Preparation method for efficiently synthesizing palladium-carbon catalyst for biotins

A palladium-carbon catalyst and synthetic biology technology, which is applied in the preparation of sugar derivatives, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as limited effects, achieve convenient maintenance, mild reaction conditions, and good heat preservation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

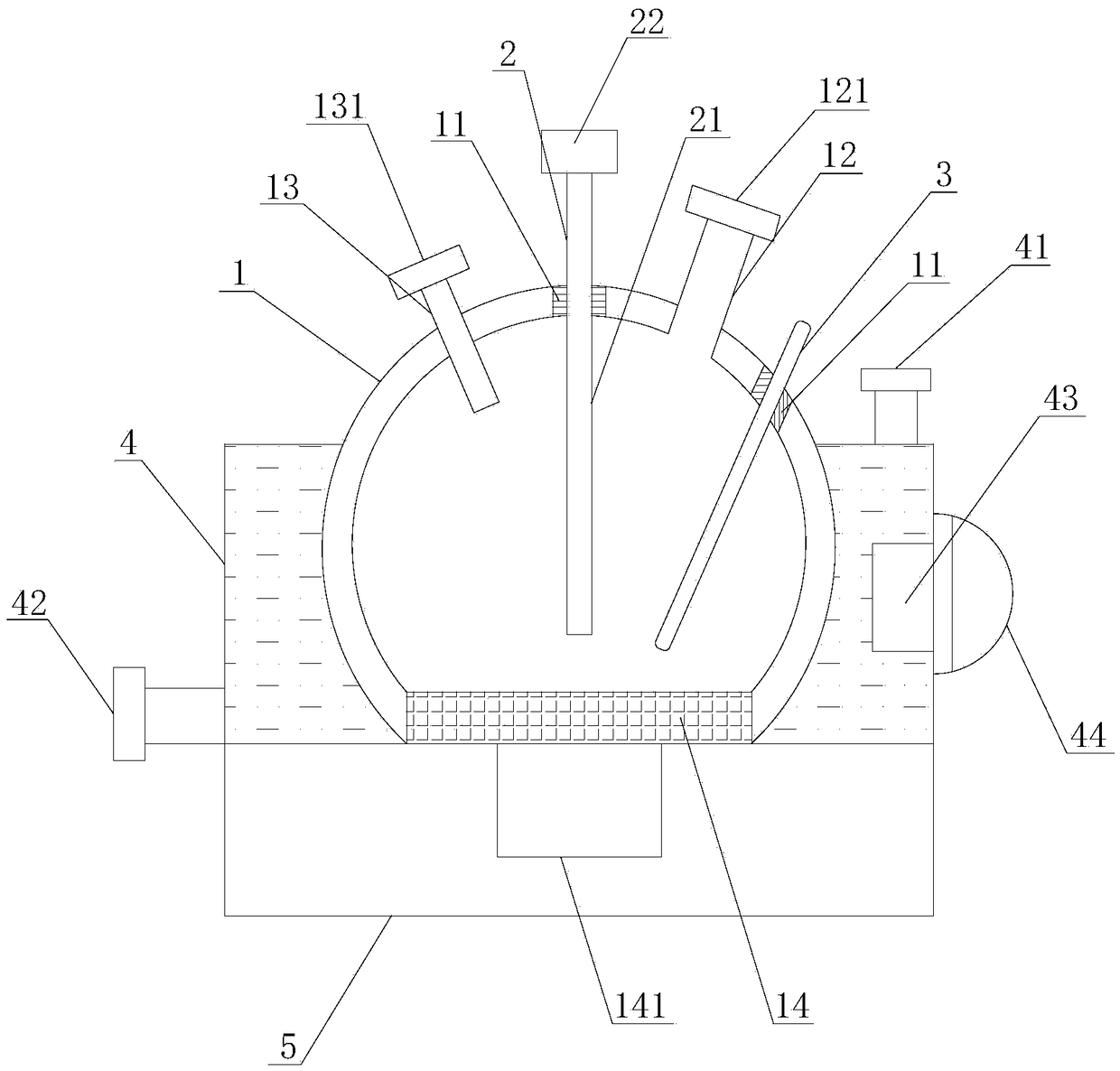

Image

Examples

preparation example Construction

[0020] A kind of preparation method of palladium-carbon catalyst for efficiently synthesizing biotin of the present invention comprises the following steps:

[0021] e) Add water into the flask, put the palladium precursor into the water, stir and dissolve, add organic acid to continue stirring and dissolve, after heating up, use alkali solution to adjust the pH value of the solution system;

[0022] f) dropping activated carbon into the solution of step a for impregnation;

[0023] g) After the impregnation is completed, add a reducing agent to the solution in step b for rapid reduction;

[0024] h) After filtering and washing the solution in step c, the palladium carbon catalyst is obtained.

[0025] Specifically, the palladium precursor described in step a is one or more mixtures of palladium dichloride, sodium chloropalladate, potassium chloropalladate, palladium nitrate, ammonium chloropalladate and chloropalladic acid, step a The organic acid described in is a mixture ...

Embodiment 1

[0032] In the 500ml flask, add 150 grams of water, take by weighing 0.45 grams of palladium equivalent chloropalladium acid solution and drop into it, then add the lactic acid aqueous solution of 6.856 grams of lactic acid equivalent, and the magnetic stirrer 14 stirs the solution under the drive of the magnetic drive motor 141, Stir to combine well. The water circulation heater 43 heats the water in the water bath 4 under the drive of the water circulation heating motor 44 to increase the temperature of the solution to 40-45°C. Use 10% sodium hydroxide solution to adjust the pH to between 6.0 and 7.0. Then add 14.55 g of activated carbon and keep warm for 8 hours. Stable temperature at 40-45°C, quickly add 0.02 molar equivalent sodium hypophosphite aqueous solution. Continue to keep warm for 4 hours. Filter and wash to obtain 15 grams of 3% palladium carbon catalyst.

[0033] In a 1000ml autoclave, add 100 grams of biotin intermediate I, 200 grams of methanol, add 5 grams...

Embodiment 2

[0035] In a 500ml flask, add 150 grams of water, weigh 0.75 grams of palladium equivalent palladium nitrate solution into it, then add 0.057 molar equivalents of citric acid aqueous solution, stir and mix evenly. Raise the temperature to 25-30°C. Use 10% sodium carbonate solution to adjust the pH to between 5.5 and 6.0. Then add 14.25 g of activated carbon and keep warm for 8 hours. Stabilize the temperature at 25-30°C, and quickly add 0.035 molar equivalent of sodium hypophosphite aqueous solution. Continue for 4 hours. 15 g of 5% palladium carbon catalyst were obtained by filtering and washing.

[0036] In a 1000ml autoclave, add 100 grams of biotin intermediate I, 200 grams of methanol, add 2.5 grams of the 5% palladium carbon catalyst prepared above, replace nitrogen three times, replace hydrogen three times, pressurize to 2.5 MPa, and heat up to 60 ° C. Leave on for 2 hours. The conversion rate of biotin intermediate I detected by liquid phase was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com