Fusion device divertor water cooling module and applied divertor cooling target board structure thereof

A divertor and water-cooling technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve problems such as insufficient cooling, achieve the effects of reducing the average heat flow, increasing the total area to withstand heat flow, and eliminating the highest temperature point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings:

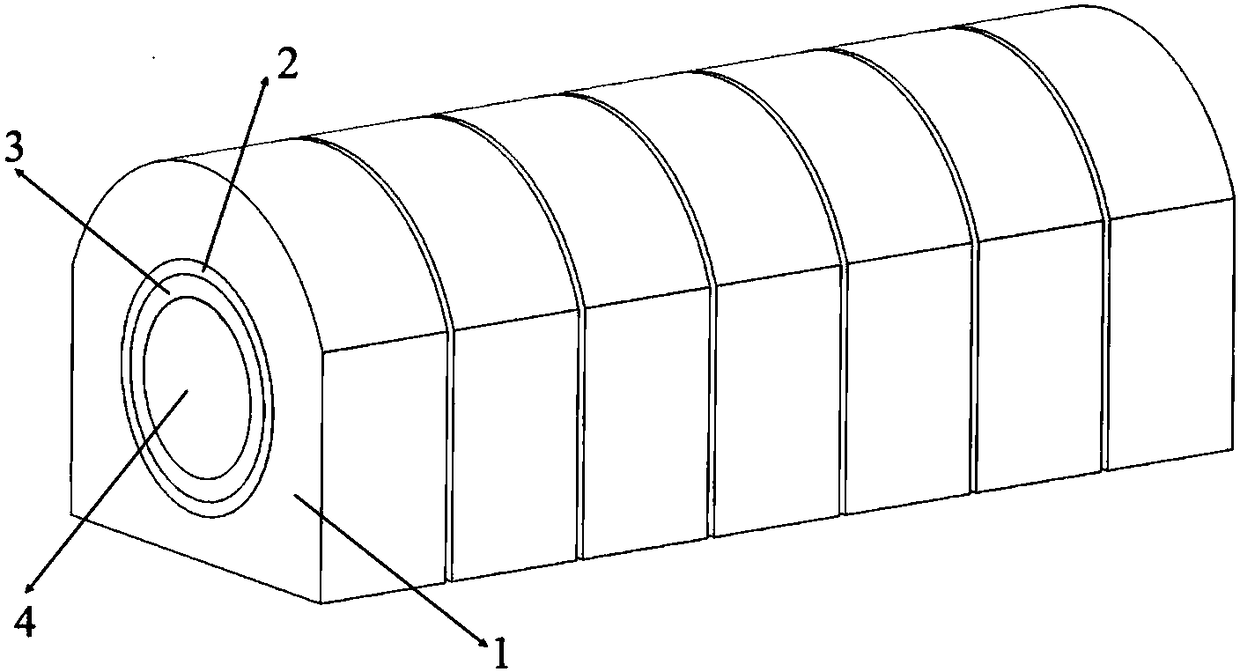

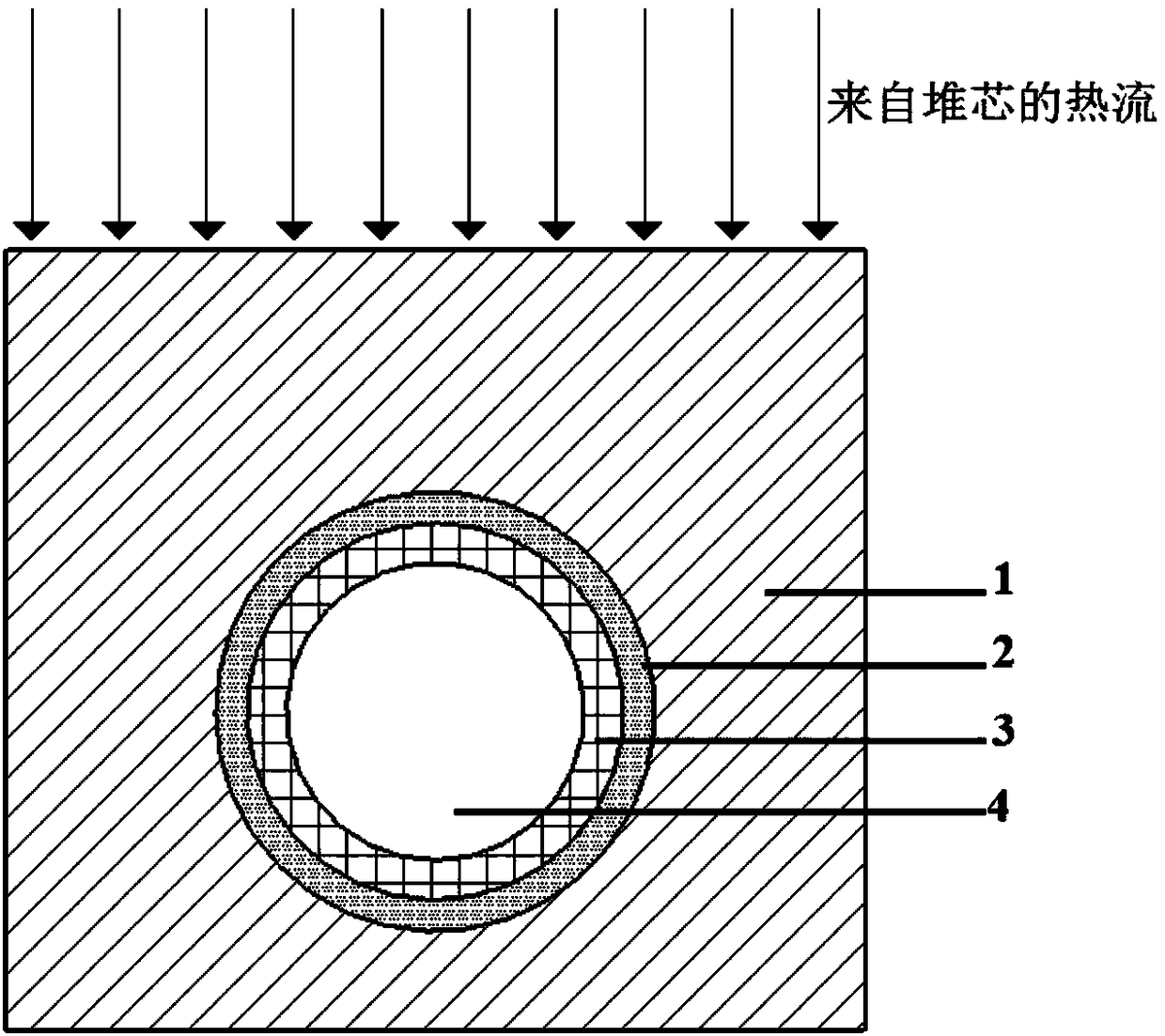

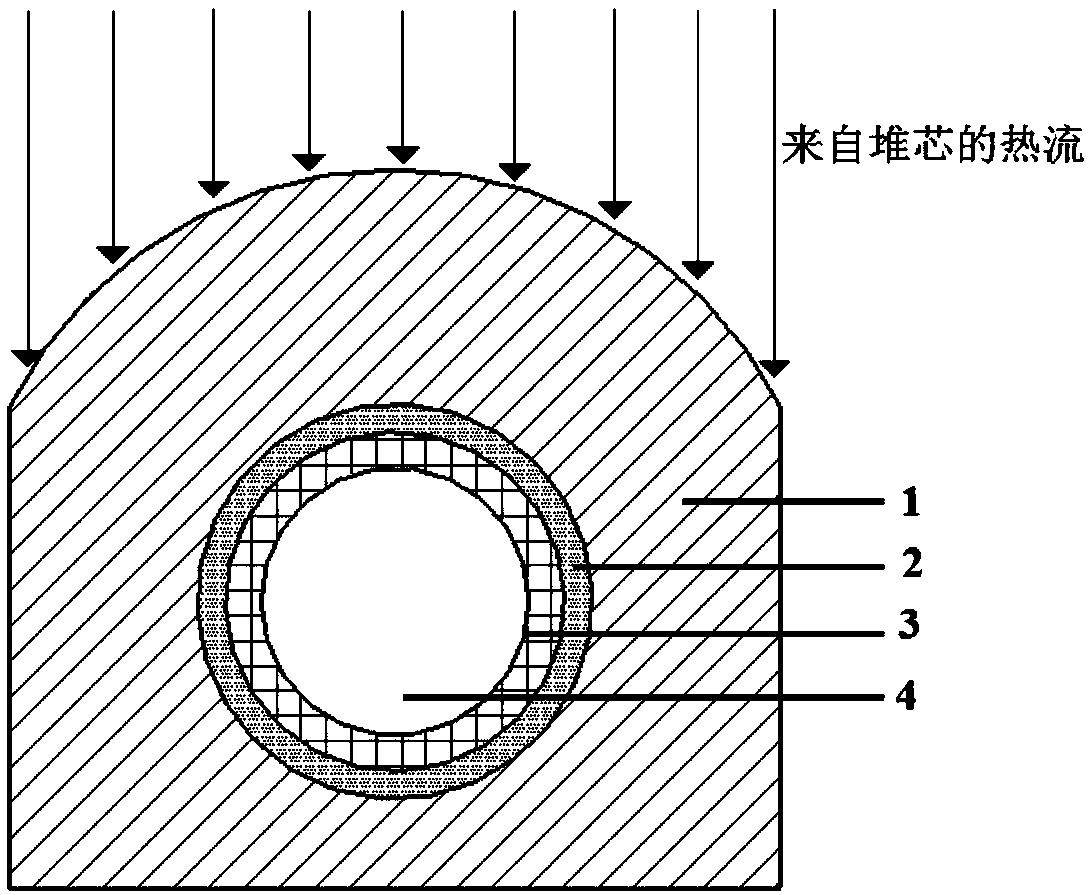

[0030] Such as figure 1 As shown, a divertor water-cooling module of a fusion device according to the present invention includes a plasma-facing structure 1 , a buffer layer structure 2 , a heat sink structure 3 and a coolant 4 . The connection between the plasma-facing structure 1, the buffer layer structure 2 and the heat sink structure 3 is hot isostatic welding. The structure is finally connected in series and then in parallel according to the axial direction of the coolant to form a whole and installed on the divertor target plate location.

[0031] Among them, the plasma-facing structure 1 is a hexahedral structure made of tungsten material, one of which protrudes in the direction of the fusion center in the shape of an arc; The component is specifically composed of a heat sink coolant pipe made of a CuCrZr alloy with high thermal conductivity; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com