Electric leakage point positioning method for aiming at floating gate

A positioning method and leakage point technology, applied in the direction of measuring electricity, measuring electrical variables, testing dielectric strength, etc., can solve the problem of low positioning accuracy and achieve the effect of ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

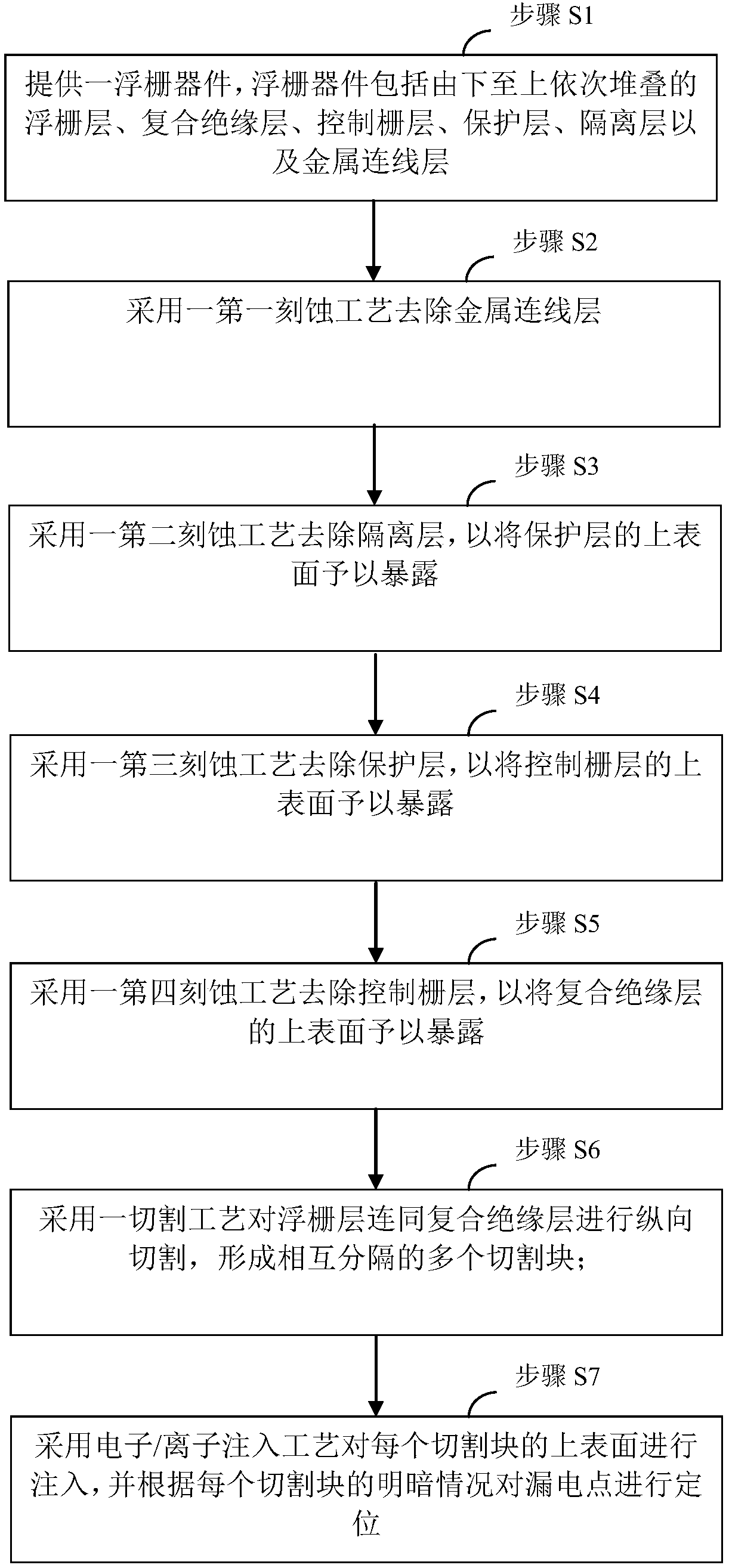

[0027] In a preferred embodiment, as figure 1 As shown, a method for positioning the leakage point of the floating gate is proposed, and the schematic diagram of the formed structure can be shown as Figure 2 ~ Figure 4 As shown, wherein, the leakage point positioning method for the floating gate may include:

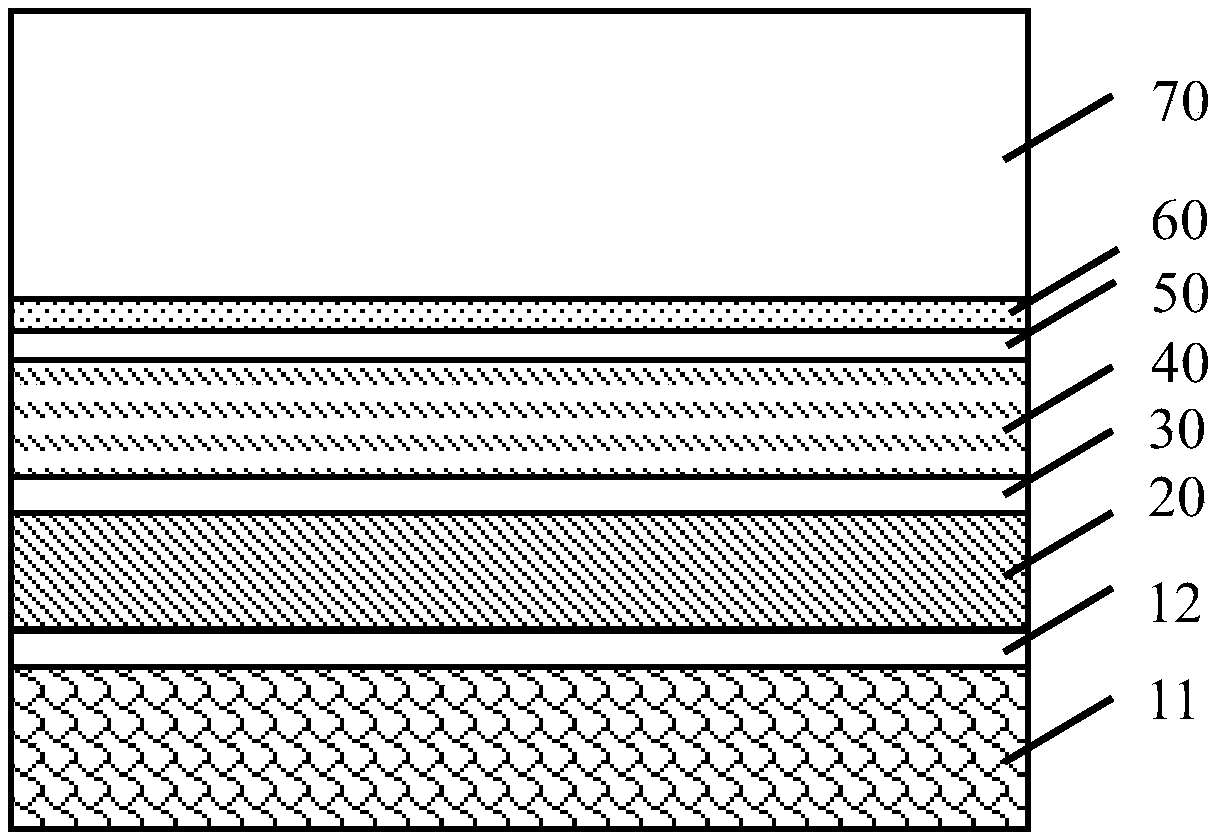

[0028] Step S1, providing a floating gate device, which includes a floating gate layer 20, a composite insulating layer 30, a control gate layer 40, a protective layer 50, an isolation layer 60, and a metal wiring layer 70 stacked sequentially from bottom to top;

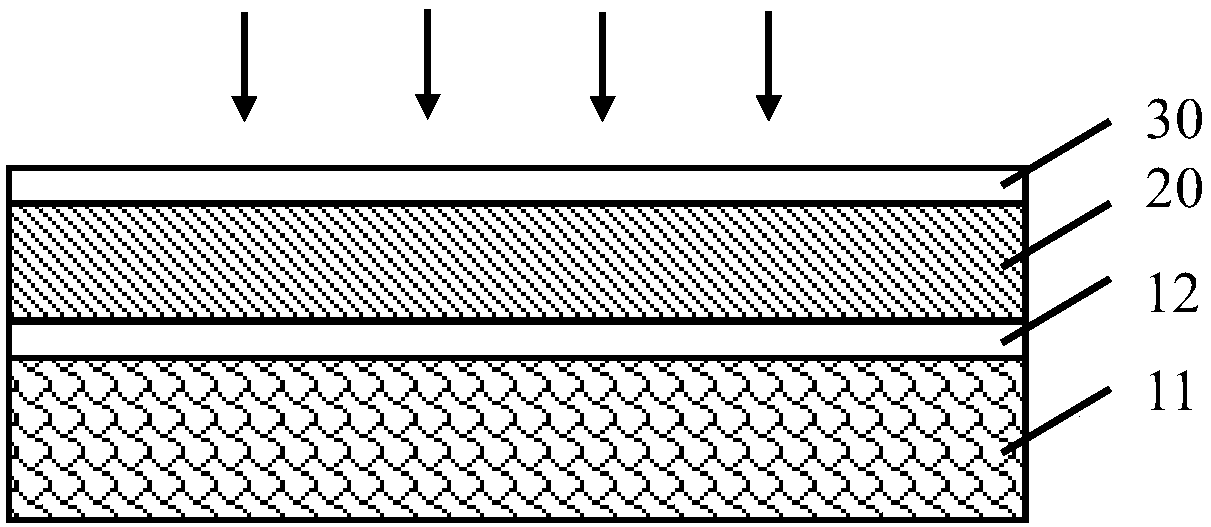

[0029] Step S2, using a first etching process to remove the metal wiring layer 70;

[0030] Step S3, using a second etching process to remove the isolation layer 60, so as to expose the upper surface of the protection layer 50;

[0031] Step S4, using a third etching process to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com