A kind of alloy etching liquid and the etching method of alloy

An etchant and etching technology, applied in the field of touch screens, can solve the problems of difficulty in grasping the degree of etching and different etching rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0037] According to the formula in Table 1, use deionized water to prepare alloy etching solution, and to figure 1 The structure shown was etched. The results are shown in Table 3.

[0038] The composition of alloy etching solution in the embodiment of the present invention 1~3 in table 1

[0039] Example acetic acid(%) Hydrogen peroxide (%) Surfactant(%) Defoamer (%) 1 5 20 1.5 1.0 2 10 20 1.5 1.0 3 10 30 1.5 1.0

[0040] The surfactant in Examples 1-3 is sodium lauryl sulfate; the defoamer is polydimethylsiloxane.

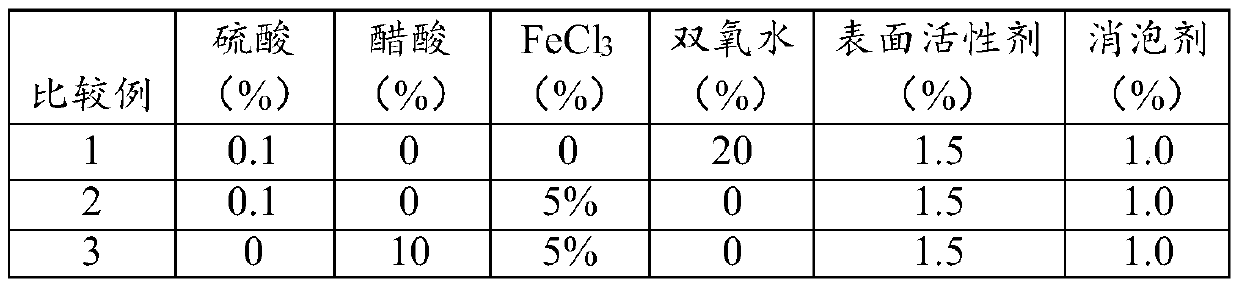

Embodiment 1~3 and comparative example 1~3

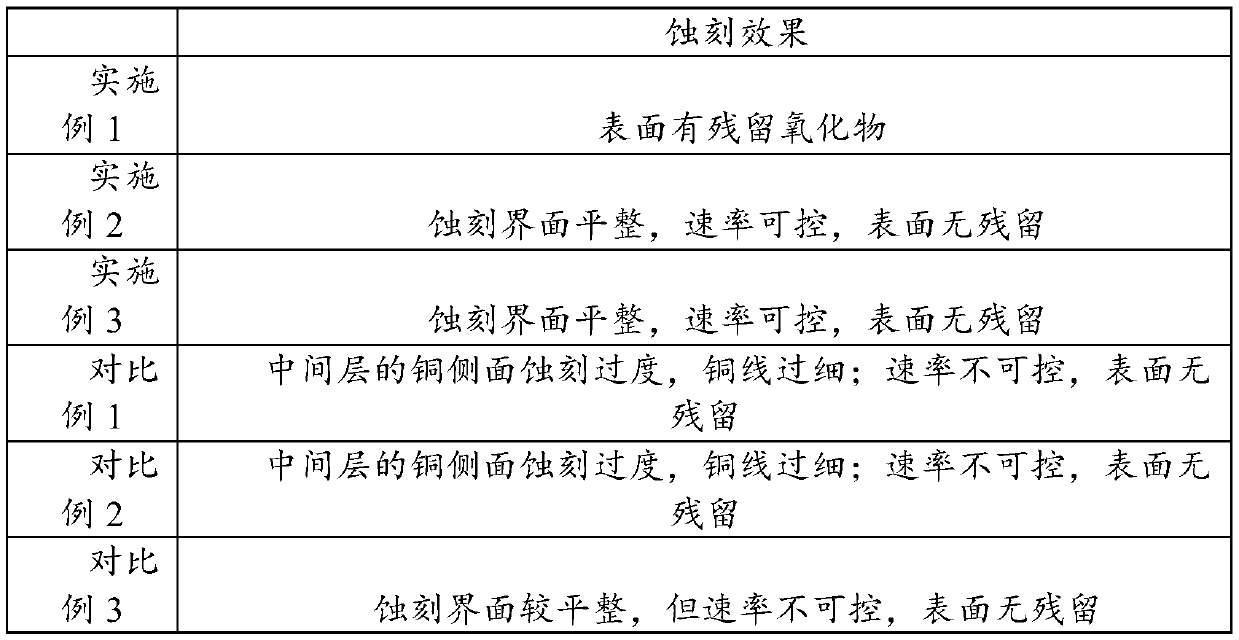

[0045] Table 3 The etching effect of alloy etching solution in the embodiment 1~3 of the present invention and comparative example 1~3

[0046]

[0047] Visible by the comparison of embodiment 2 and comparative example 1, strong acid has greater influence to the etching speed of copper, can influence the effect of etching;

[0048] By the comparison of embodiment 1 and embodiment 2, it can be seen that the amount of acetic acid content has a greater impact on the etching rate of copper, and the too low content of acetic acid will cause endless etching;

[0049] Visible by the comparison of embodiment 2 and comparative example 3, FeCl 3 It is not as good as hydrogen peroxide in controlling the rate of etching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com