Functional negative ion coating and preparation method thereof

A negative ion coating and functional technology, applied in the field of functional coatings and its preparation, can solve the problem of low negative ion release, achieve low radioactivity, increase the concentration of negative ions, and ensure the safety of formula components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

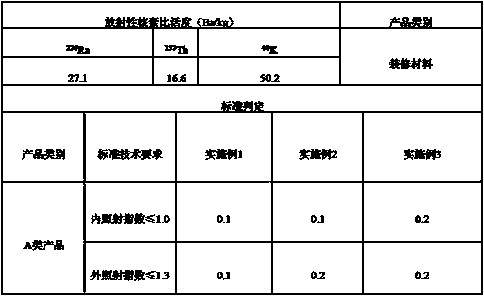

Examples

Embodiment 1

[0037] This functional negative ion coating is mainly made of the following raw materials:

[0038] Purified water 18kg

[0039] Acrylic adhesive 25 kg

[0040] Sodium cetyl sulfonate 0.2 kg

[0041] Heavy calcium powder 40 kg

[0042] Lithopone 7 kg

[0043] Sodium lactate 0.2 kg

[0044] Suspending agent 0.2kg

[0045] Simethicone 0.2kg

[0046] Carboxymethylcellulose 2 kg

[0047] Tourmaline 15 kg.

[0048] The preparation method of the coating is as follows: at room temperature, first mix 15kg 2800~4000mesh tourmaline, 5kg pure water, 5kg heavy calcium powder, 2kg lithopone and 0.1kg suspending agent in a high-speed dispersing machine, and mix it at 60000r / min Stir for 30 minutes at a rotating speed to obtain a paste-like anion additive.

[0049] Put 13kg of pure water in a disperser, and add 25kg of acrylic adhesive while stirring at a speed of 3000r / min, and then add 0.2kg of sodium hexadecylsulfonate after stirring for 5 minutes, and continue stirring for 5 min...

Embodiment 2

[0051] This functional negative ion coating is mainly made of the following raw materials:

[0052] Purified water 20kg

[0053] Acrylic adhesive 25 kg

[0054] Sodium cetyl sulfonate 0.2 kg

[0055] Titanium dioxide 36 kg

[0056] Lithopone 10kg

[0057] Sodium dehydroacetate 0.3kg

[0058] Suspending agent 0.3kg

[0059] Simethicone 0.3kg

[0060] Hydroxypropyl methylcellulose 2 kg

[0061] Tourmaline 10 kg;

[0062] The preparation method of the coating is as follows: at room temperature, first mix 10kg of 2800~4000mesh tourmaline, 10kg of pure water, 10kg of titanium dioxide, 0.2kg of lithopone and 0.2kg of suspending agent in a high-speed disperser, and mix them at a speed of 48000r / min. Stir for 50 minutes to obtain a paste-like anion additive.

[0063]Put 10kg of pure water in a disperser, and add 25kg of acrylic adhesive while stirring at a speed of 3600r / min, and then add 0.2kg of sodium hexadecylsulfonate after stirring for 10 minutes, and continue stirring ...

Embodiment 3

[0065] This functional negative ion coating is mainly made of the following raw materials:

[0066] Purified water 18kg

[0067] Acrylic adhesive 25 kg

[0068] Sodium cetyl sulfonate 0.2 kg

[0069] Titanium dioxide 38 kg

[0070] Lithopone 8 kg

[0071] Potassium sorbate 0.2 kg

[0072] Suspending agent 0.3kg

[0073] Simethicone 0.2kg

[0074] Sodium caseinate 3 kg

[0075] Tourmaline 20kg;

[0076] The preparation method of the coating is as follows: at room temperature, first mix 20kg of 2800~4000mesh tourmaline, 8kg of pure water, 8kg of titanium dioxide, 1kg of lithopone and 0.2kg of suspending agent in a high-speed disperser, and mix them at a speed of 60000r / min. Stir for 30 minutes to obtain a paste-like anion additive.

[0077] Put 10kg of pure water in a disperser, and add 25kg of acrylic adhesive while stirring at a speed of 3000r / min, and then add 0.2kg of sodium hexadecylsulfonate after stirring for 5 minutes, and continue stirring for 5 minutes to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com