High-quality powder recovery device

A recycling device, high-quality technology, applied in the field of 3D printing, can solve the problem of not being able to completely separate it, and achieve the effect of preventing oxidation and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

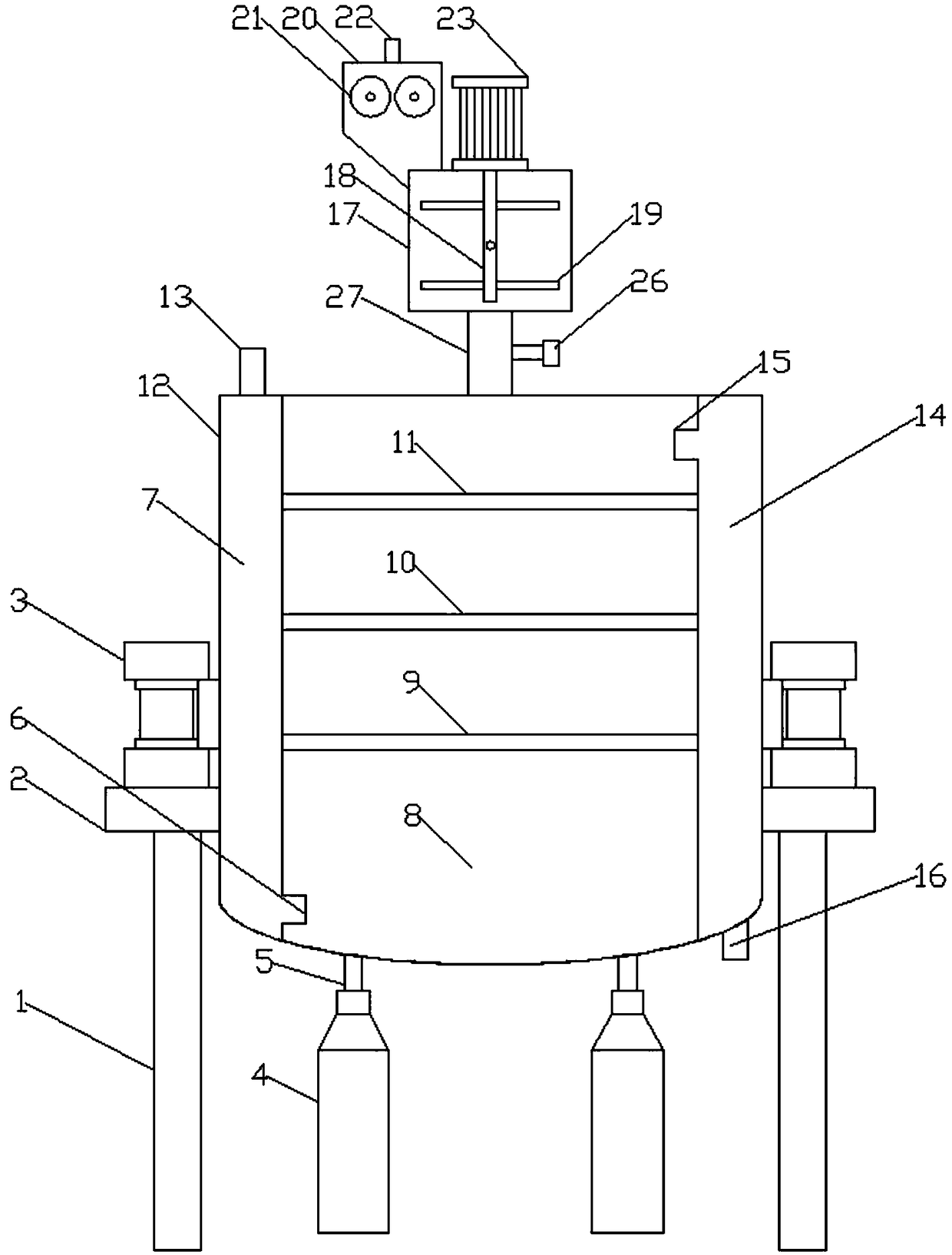

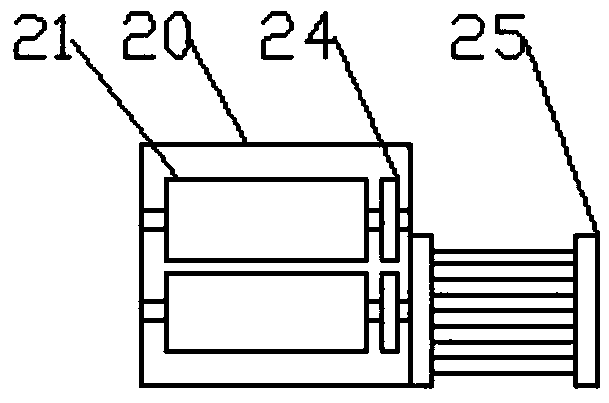

[0013] Figure 1-2 Show the specific embodiment of the present invention: a kind of high-quality powder recovering device, comprise the supporting leg 1 of ring table 2 and its bottom, described ring table 2 two ends are provided with vibrating motor 3, the vibrating motor 3 The output shaft is provided with a sieve box 12, and the sieve box 12 is respectively provided with a left cavity 7, a powder sieving cavity 8 and a right cavity 14, and the upper end of the sieve box 12 is provided with an air inlet pipe 13 communicating with the left cavity 7 , the bottom of the sieve box 12 is provided with an air outlet pipe 16 communicating with the right cavity 14 and a powder outlet pipe 5 communicating with the powder sieving chamber 8, the lower end of the powder outlet pipe 5 is connected with a recovery steel cylinder 4, and the left cavity The bottom of the 7 is provided with an air inlet 6 communicating with the powder sieving chamber 8, and the upper end of the right cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com