Method and device for measuring coal wettability under high pressure through low-field nuclear magnetic resonance

A low-field nuclear magnetic resonance and wettability technology, which is applied in the fields of nuclear magnetic resonance analysis, measurement devices, and material analysis through resonance, can solve the problems of insignificant changes in relaxation time, large errors, and slow water droplet migration. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Measuring device

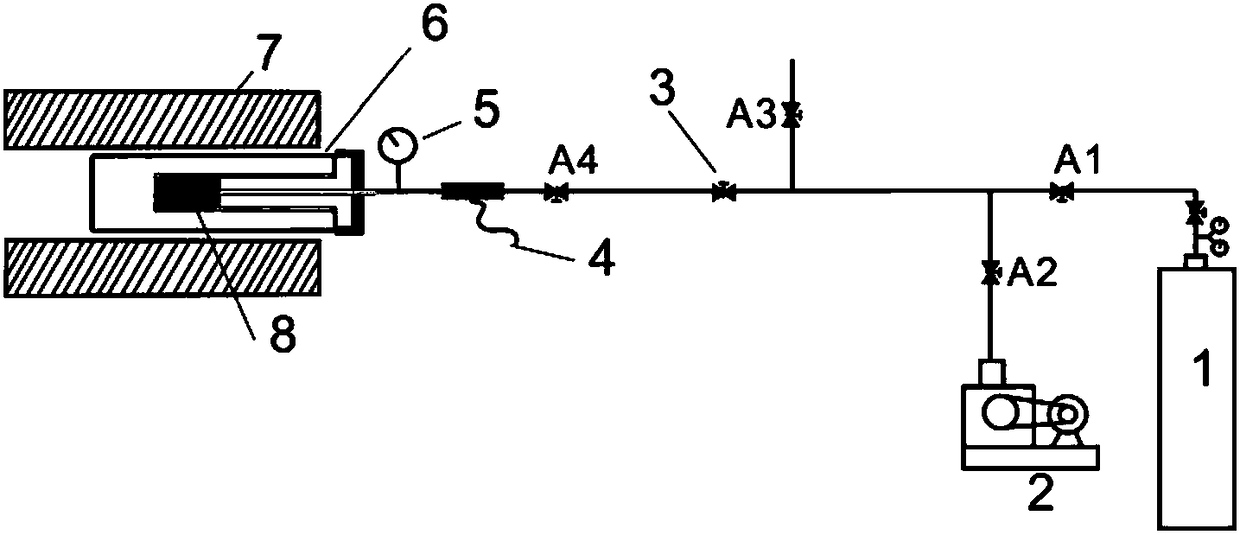

[0046] See attached image 3 , a device for measuring wettability of coal under high pressure by using low-field nuclear magnetic resonance, comprising a gas source (1), a sealed constant pressure system and a nuclear magnetic magnet (7), and the nuclear magnetic resonance magnet (7) is connected to a low-field nuclear magnetic resonance instrument. The sealed constant pressure system consists of a sealed sample cavity (6) for placing samples and pressure regulating valves (A1, A2, A3, A4) for adjusting pressure. The sealed constant pressure system is connected to the gas source (1) through the valve A1, connected to the gas booster pump (2) through the valve A2, and connected to the external environment through the valve A3. The gas (1) is connected to the sealed sample chamber (6) through a pressure regulating valve (3), a temperature sensor (4), a pressure sensor (5) and a valve A4. The sealed sample chamber (6) has an outer diameter...

Embodiment 2

[0047] Embodiment 2 measures gas pressure and is the CO of 4MPa 2 Wettability of Coal Powder in Environment

[0048] Follow the steps below:

[0049] 1. Sample preparation and loading

[0050] Select the sample SJZ from Qinshui Basin, grind about 100g of 60-80 mesh pulverized coal sample, weigh it, put it in a drying oven and dry it to constant weight; measure the apparent density of the pulverized coal sample ρ=1.55g / cm 3 ;Measure to obtain the volume V of the sample tank c =62.8cm 3 According to the formula (2), the required sample mass m=68.14g is calculated under the intergranular porosity of 30%, and the weighing 62.14g sample is loaded into the sample tank.

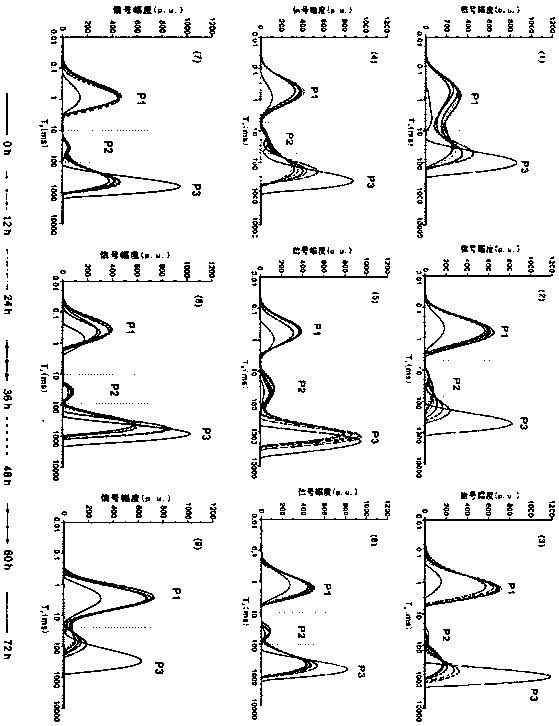

[0051] 2. Select low-field NMR measurement parameters

[0052] Select the CPMG measurement sequence; the specific parameters of the measurement are as follows: echo time (TE) = 0.3ms, number of superpositions (SCANS) = 64, waiting time (TW) = 3s, number of echoes (NECH) = 18000; set the test environment at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com