Extractor hood and integrated type steam generation module thereof

A technology for generating modules and range hoods, applied in the directions of steam generation, steam generation methods, and oil fume removal, etc., can solve problems such as unfavorable structural optimization and modular design of the whole machine, higher pressure requirements of water pumps, and increased risk of water leakage, etc. Achieve the effect of facilitating modular design, reducing the risk of water leakage, and eliminating the need for pump structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

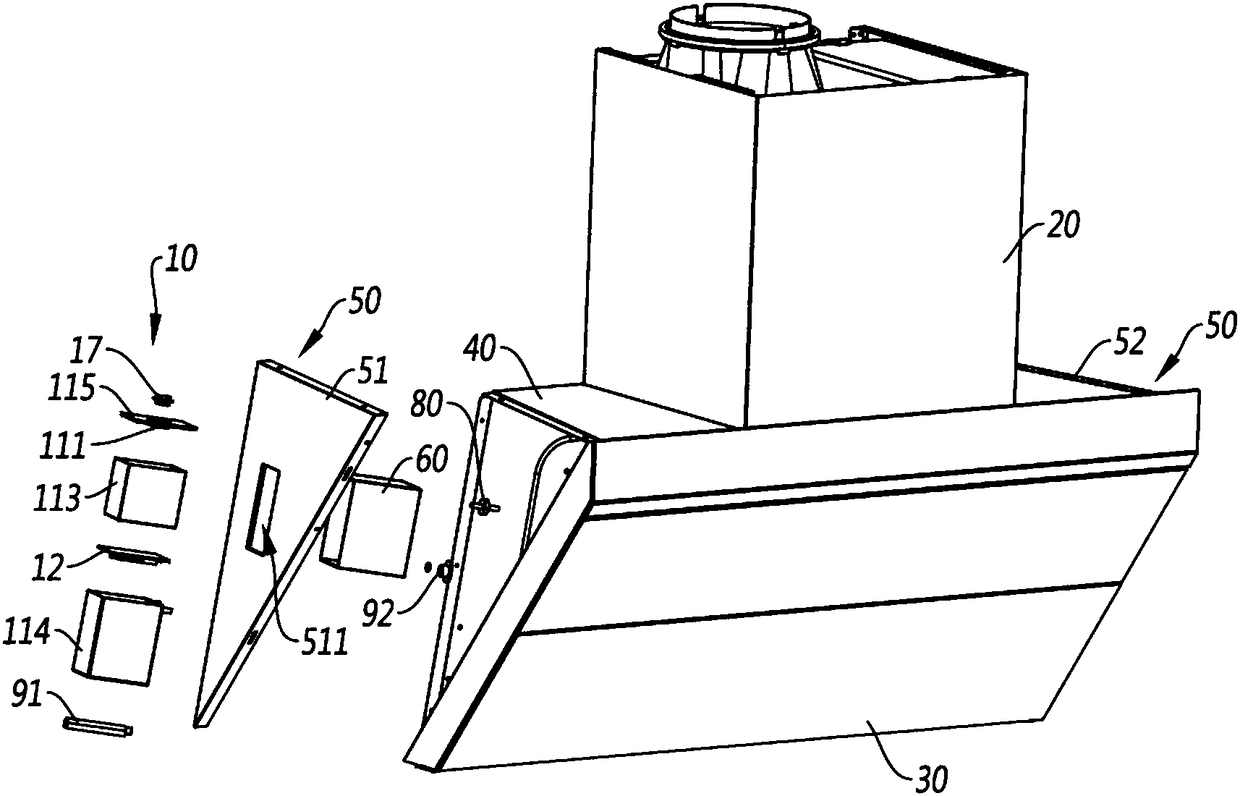

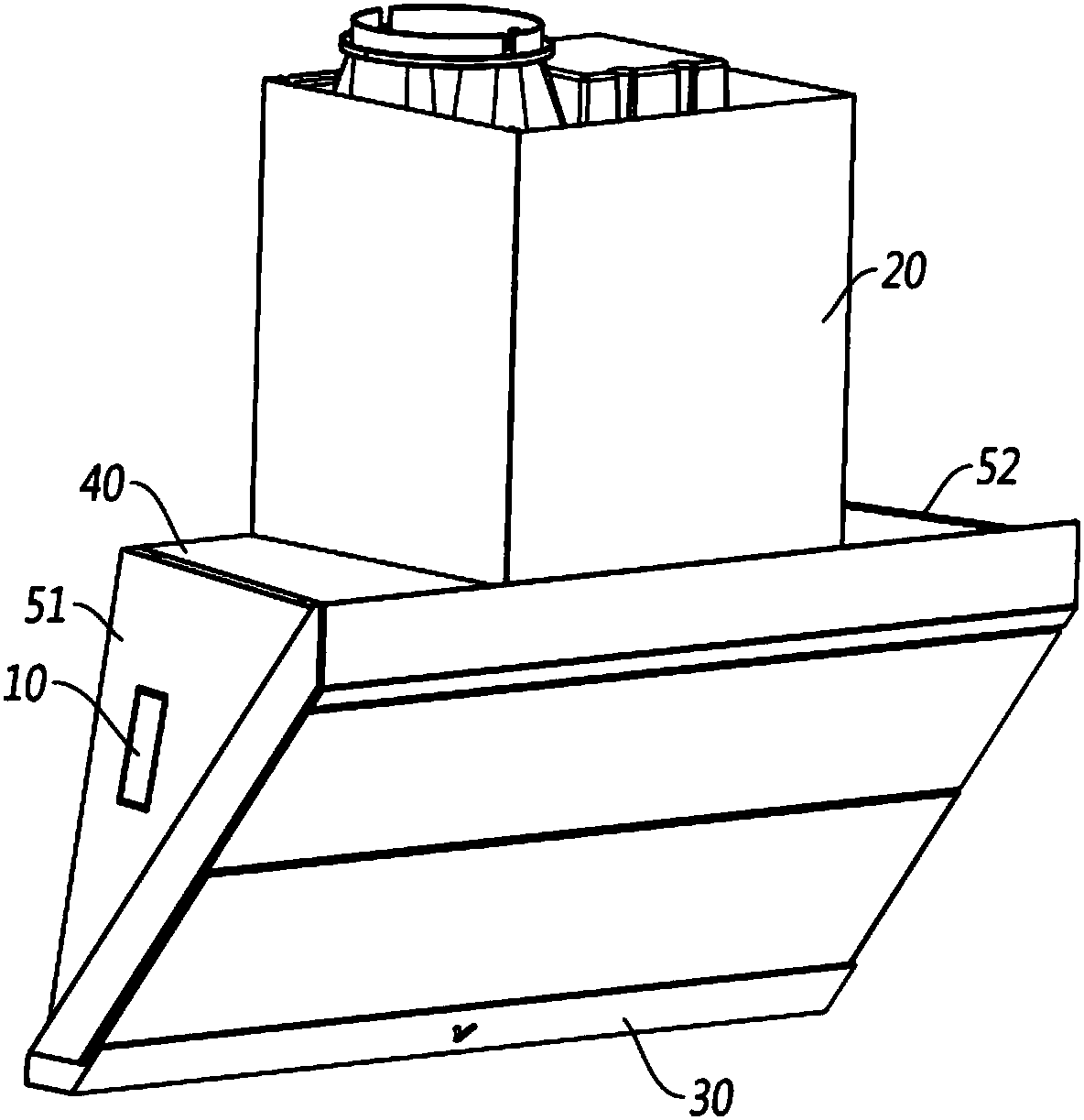

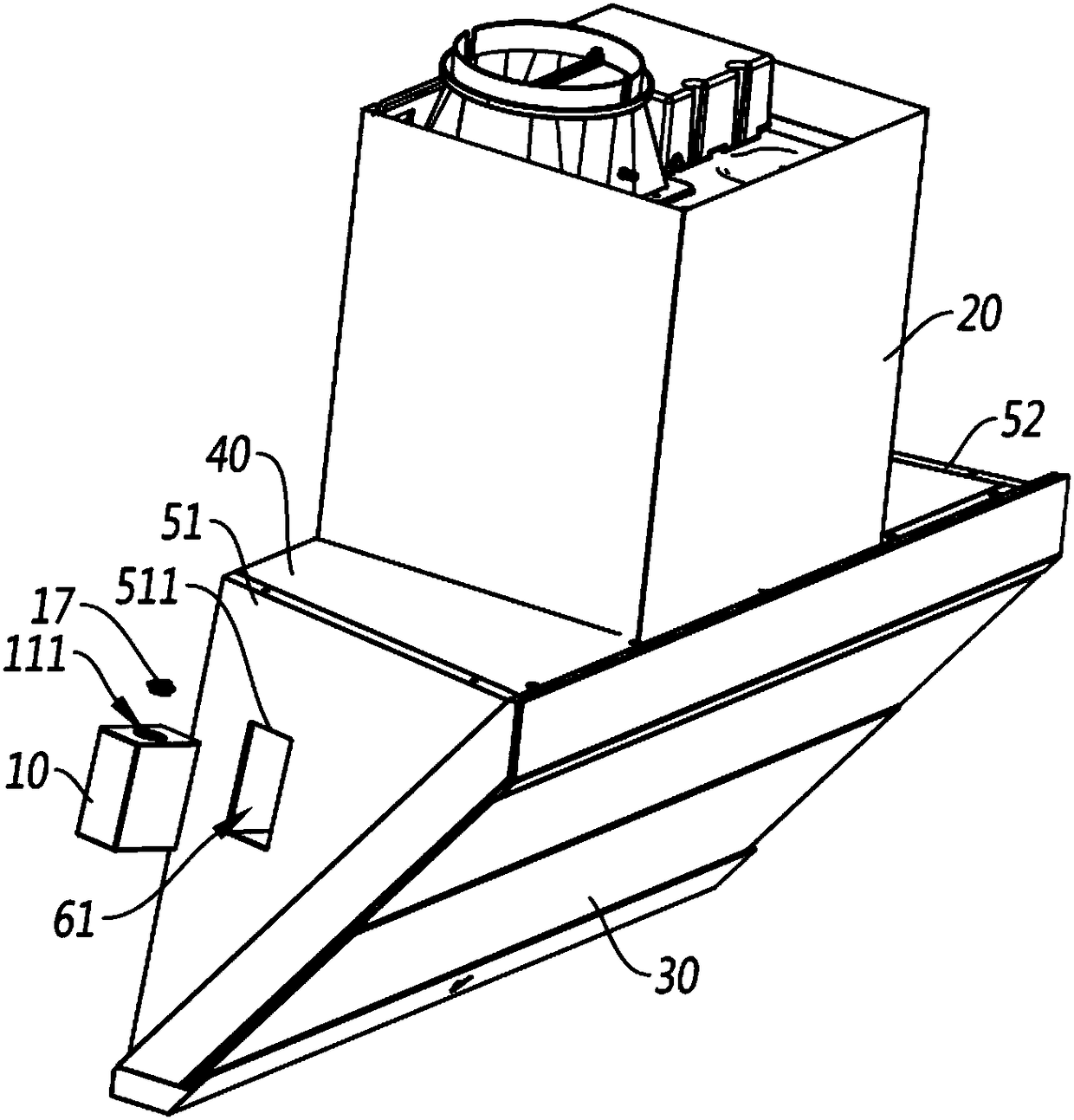

[0027] Such as Figure 1 to Figure 8 As shown, an integrated steam generating module 10 applied to a range hood according to a preferred embodiment of the present invention includes: an airtight water storage container 11, a heating body 12 arranged at the bottom of the water storage container 11, an electrical Connected to the power plug 13 of the heating body 12 , the water storage container 11 is provided with a water injection port 111 and a steam outlet 112 for discharging steam, and a steam pipe joint 14 is connected to the steam outlet. When in use, the power plug 13 is connected to an external power supply, so that the heating body 12 heats the water in the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com