A compact double-rod hydraulic cylinder

A compact, hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of use in places with limited space, long cylinder length, inconvenient use and installation, etc., to reduce volume, reduce cylinder length, and facilitate installation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

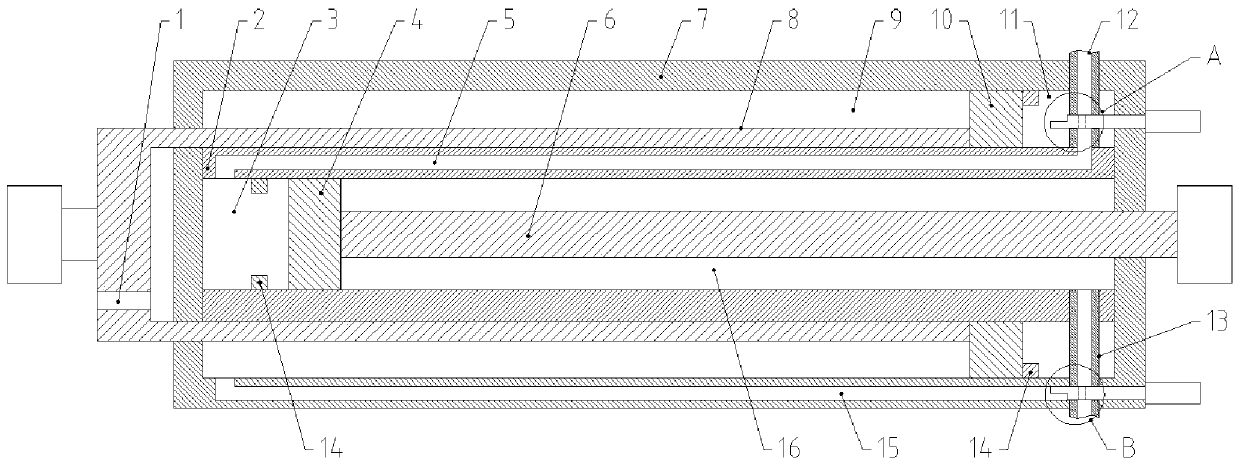

[0025] A compact double-rod hydraulic cylinder, comprising an outer cylinder 7, an inner cylinder 2 is arranged inside the outer cylinder 7, a hollow hydraulic rod 8 is sleeved on the outer wall of the inner cylinder 2, the left end of the hollow hydraulic rod 8 protrudes from the outer cylinder 7, and the hollow hydraulic rod 8. The right end is connected with an annular piston 10 that is in contact with the outer wall of the inner cylinder 2 and the inner wall of the outer cylinder 7. The left and right sides of the annular piston 10 are respectively the outer oil return chamber 9 and the outer oil inlet chamber 11. The inner cylinder 2 is provided with a piston 4 The hydraulic rod 6, the left and right sides of the piston 4 are respectively the inner oil inlet chamber 3 and the inner oil return chamber 16, the right end of the hydraulic rod 6 extends out of the outer cylinder 7, and the inner cylinder 2 is provided with an oil inlet connected to the inner oil inlet chamber 3 ...

Embodiment 2

[0029] This embodiment improves on the basis of Embodiment 1:

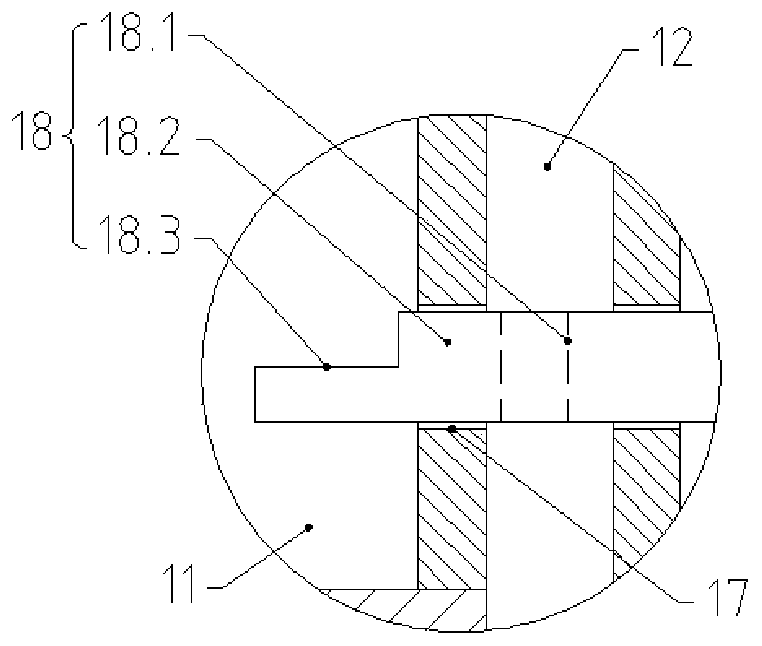

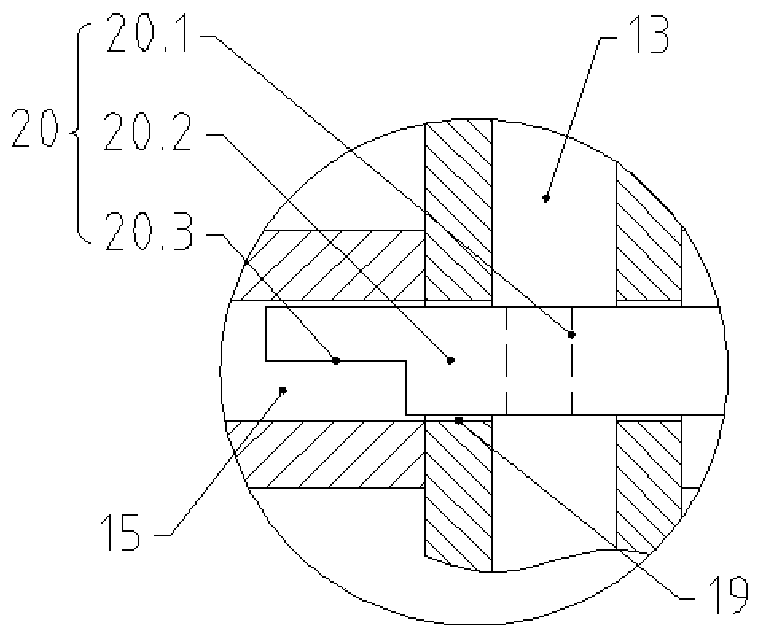

[0030] The oil inlet hole 17 and the oil return hole 19 are respectively provided with a pipeline switching mechanism a18 and a pipeline switching mechanism b20.

[0031] The advantages of the above improvements are: the pipeline switching mechanism a and the pipeline switching mechanism b can realize the switching of the oil inlet and oil return of the oil inlet pipe and the oil return pipe, and realize that the hollow hydraulic rod and the hydraulic rod can perform telescopic work independently, while still being able to Simultaneous expansion and contraction, so that the device can meet different usage requirements.

Embodiment 3

[0033] This embodiment improves on the basis of Embodiment 2:

[0034] The pipeline switching mechanism a18 includes a cylinder a18.2 whose rod body traverses through the oil inlet pipe 12 and corresponds to the oil inlet hole 17. The diameter of the rod body of the cylinder a18.2 is the same as the inner diameter of the oil inlet pipe 12. 12 The pipeline is connected to the matched oil inlet 18.1, and the end of the rod body of the cylinder a18.2 is provided with a semi-cylindrical notch a18.3 on the outer side of the outer cylinder 7.

[0035] Working principle: Working principle: When the hollow hydraulic rod 8 needs to be extended, the rod body of the cylinder a18.2 extends to the gap a corresponding to the pipeline of the oil inlet pipe 12. At this time, the rod body of the cylinder a18.2 on the back of the gap a18.3 is blocked The oil inlet pipe 12 pipeline before the oil inlet channel 5 opens the oil inlet hole 17 at the same time, and the hydraulic medium oil enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com