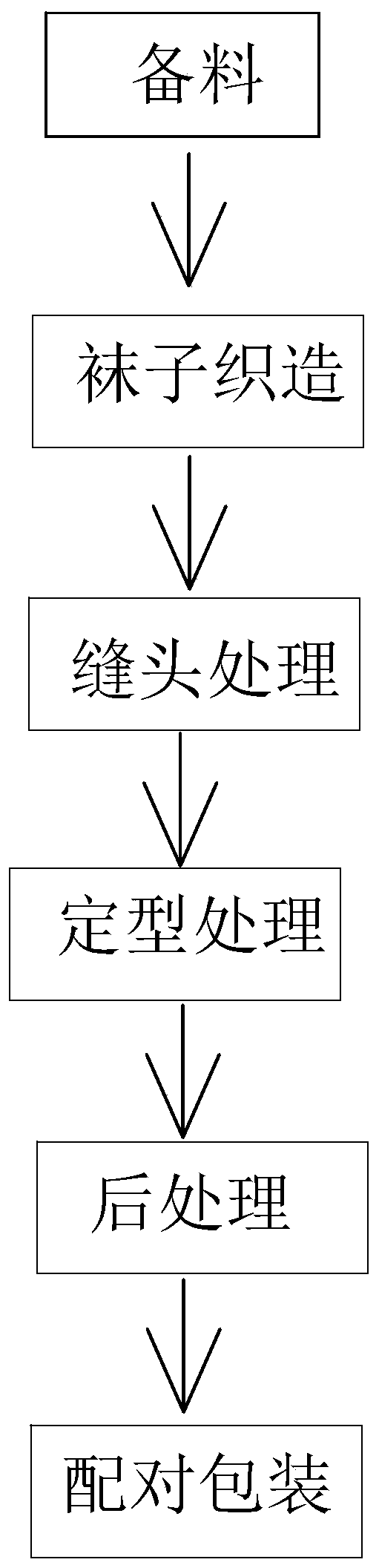

Production process of anti-static high moisture-absorbing reinforced socks

A production process and high moisture absorption technology, applied in socks, pantyhose, knitting, etc., can solve the problems of poor foot comfort of socks, achieve strong moisture absorption and hydrophilic function, good anti-shedding function, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

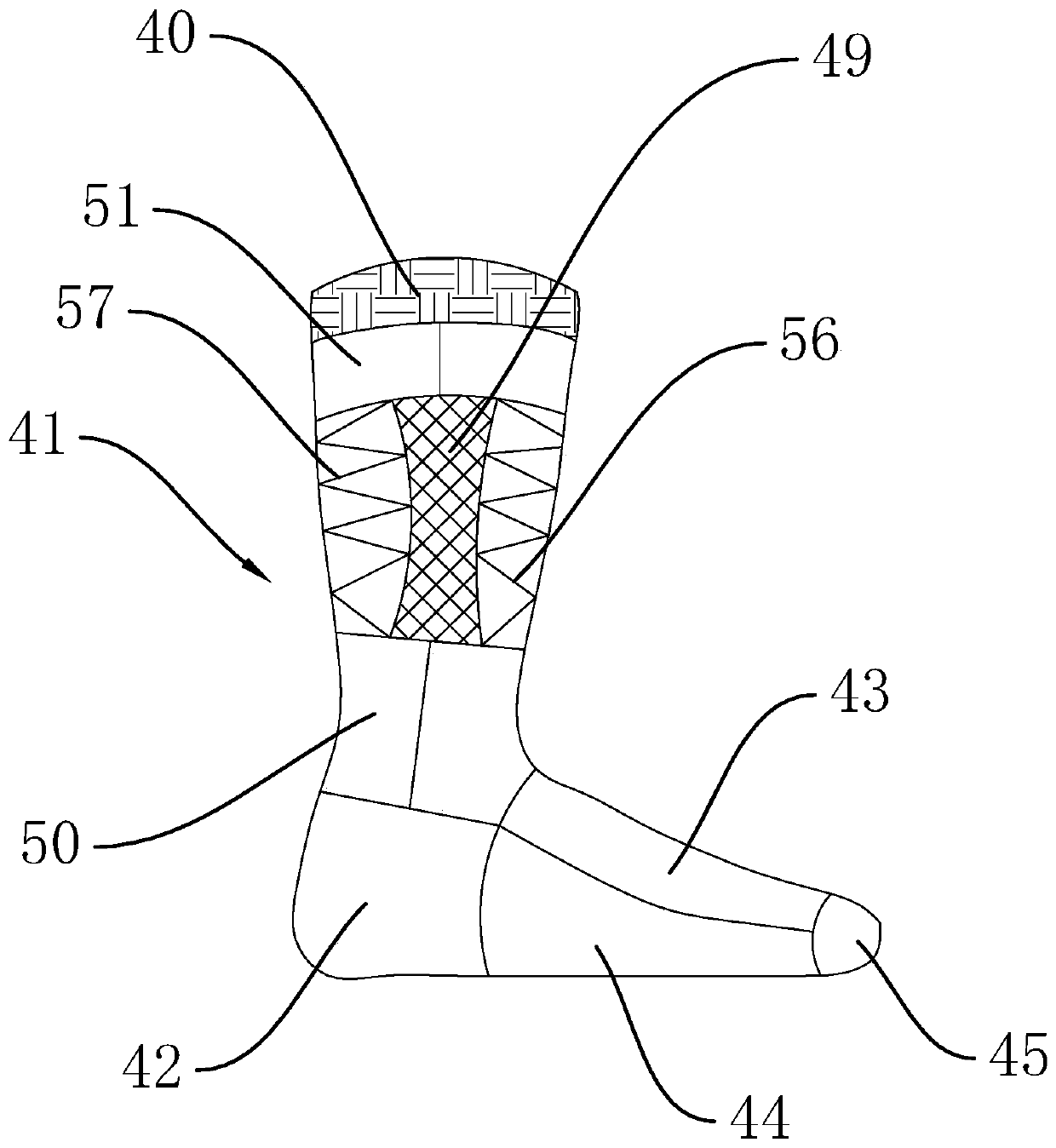

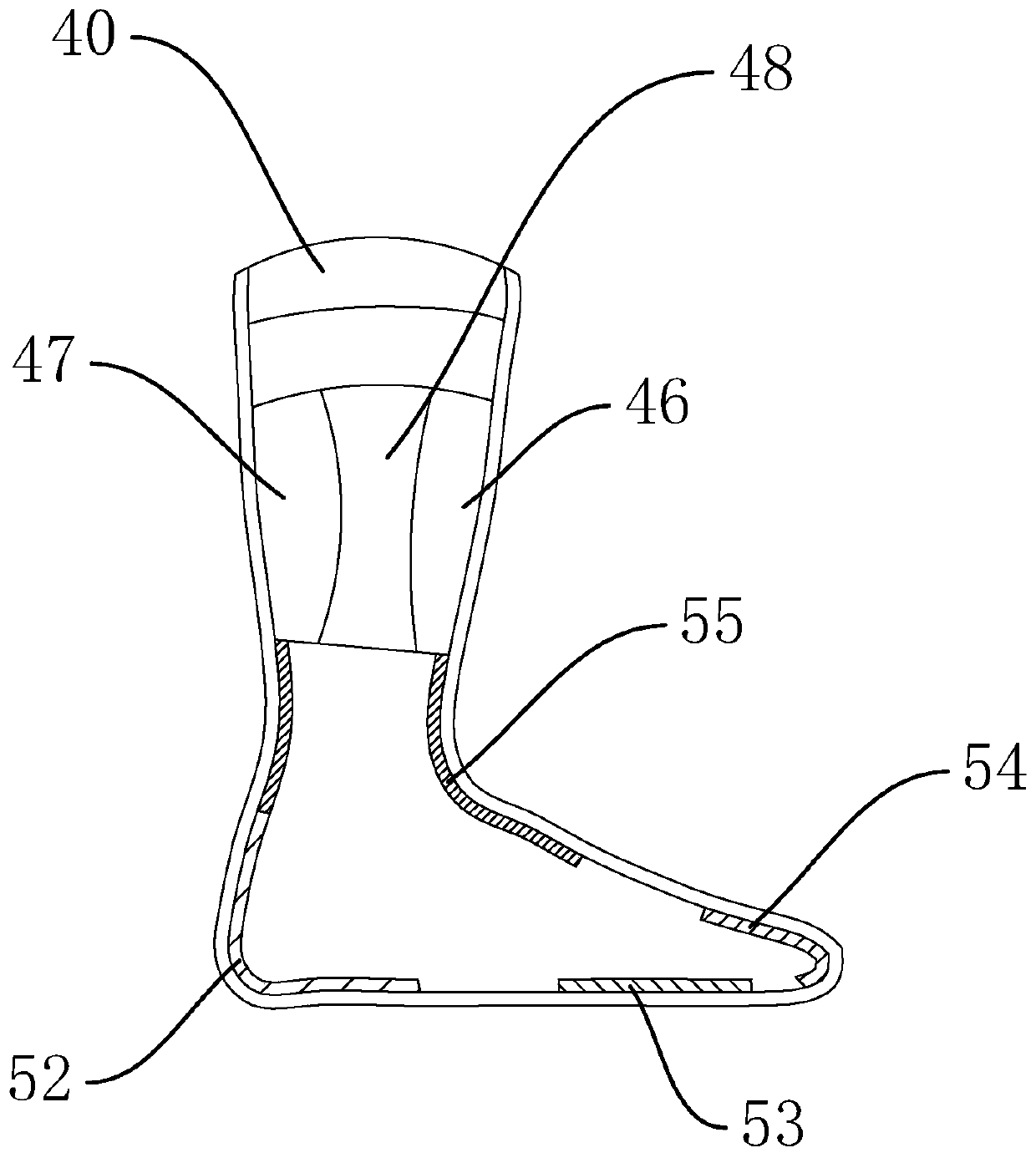

[0045] like figure 1 and figure 2As shown, the present invention provides a kind of anti-static high moisture-absorbing reinforced socks, comprising a sock body, the sock body includes a sock opening 40, a sock tube 41, a sock heel 42, a sock face 43, a sock bottom 44 and a sock toe 45, and the sock body adopts modified The interweaving of high-strength polyester low-stretch yarn, porous polyester yarn and soluble spandex makes the socks have strong hygroscopic and hydrophilic functions, good resilience, anti-static, and good anti-shedding functions.

[0046] Specifically, the sock tube 41 includes a tensioning portion 46, a tensioning portion 2 47, a mesh portion 1 48 and a mesh portion 2 49; the tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com