Three-dimensional and multi-directional hemp fiber blended fabric

A hemp fiber and three-dimensional technology, which is applied in the field of hemp fiber blended three-dimensional multi-directional fabrics, can solve the problems of high rigidity of hemp fiber, monotonous style, and easy wrinkle of pure hemp fabric, and achieve good wrinkle resistance and strong three-dimensional layering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, preparation and performance test of hemp blended three-dimensional multi-directional fabric

[0025] 1. Weaving process:

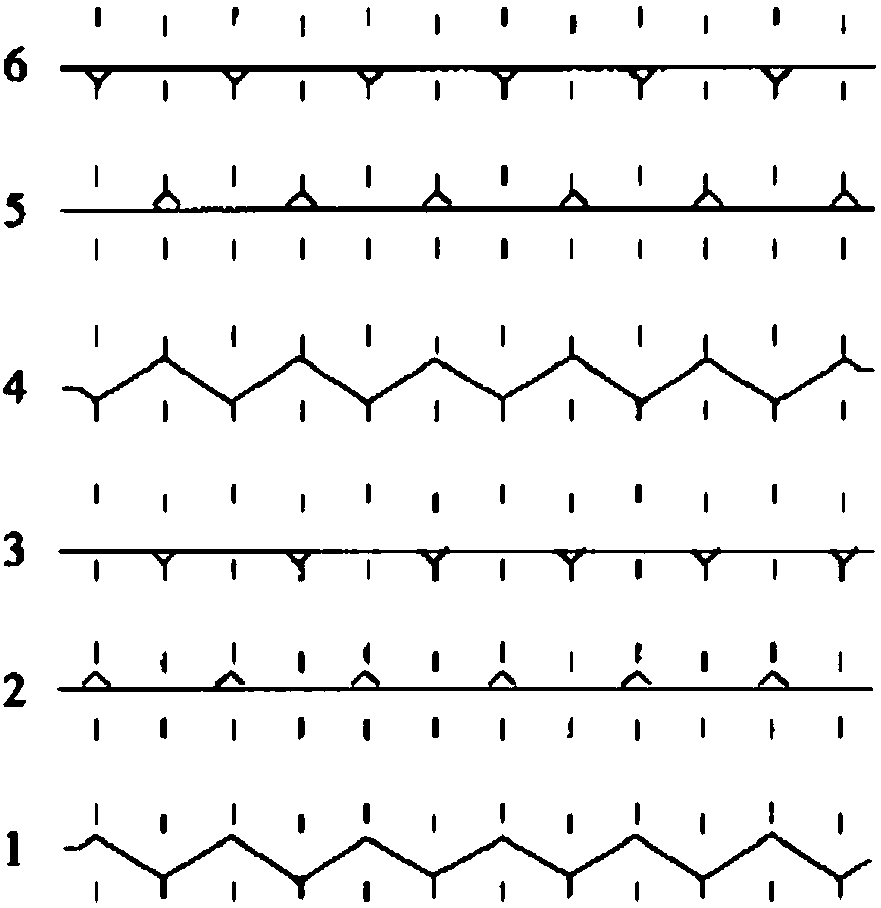

[0026] The present invention adopts the double-sided circular knitting machine with upper two and lower four multi-needle paths with a tube diameter of 16 inches and a machine number of E22. figure 1 The weaving structure shown in (weaving diagram) is a complete weave formed by six roads, in which the 2nd and 5th roads use weft yarns; the 3rd and 6th roads use warp yarns, the 1st and 4th roads use vertical yarns, and weft yarns are woven The reverse side of the hemp blended three-dimensional multidirectional fabric, the front side of the hemp blended three-dimensional multidirectional fabric is woven with warp yarns, and the front and back sides of the hemp blended three-dimensional multidirectional fabric are connected by drapes.

[0027] 2. Ingredients

[0028] Warp composition: 100% high-strength moisture-absorbing and sweat-wicki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com