Method for preparing Mo-doped Al2O3 high-resistance film by atomic layer deposition

An atomic layer deposition and high-resistance technology, which is applied in coating, metal material coating process, gaseous chemical plating, etc. Excellent thermal stability, simple preparation process, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

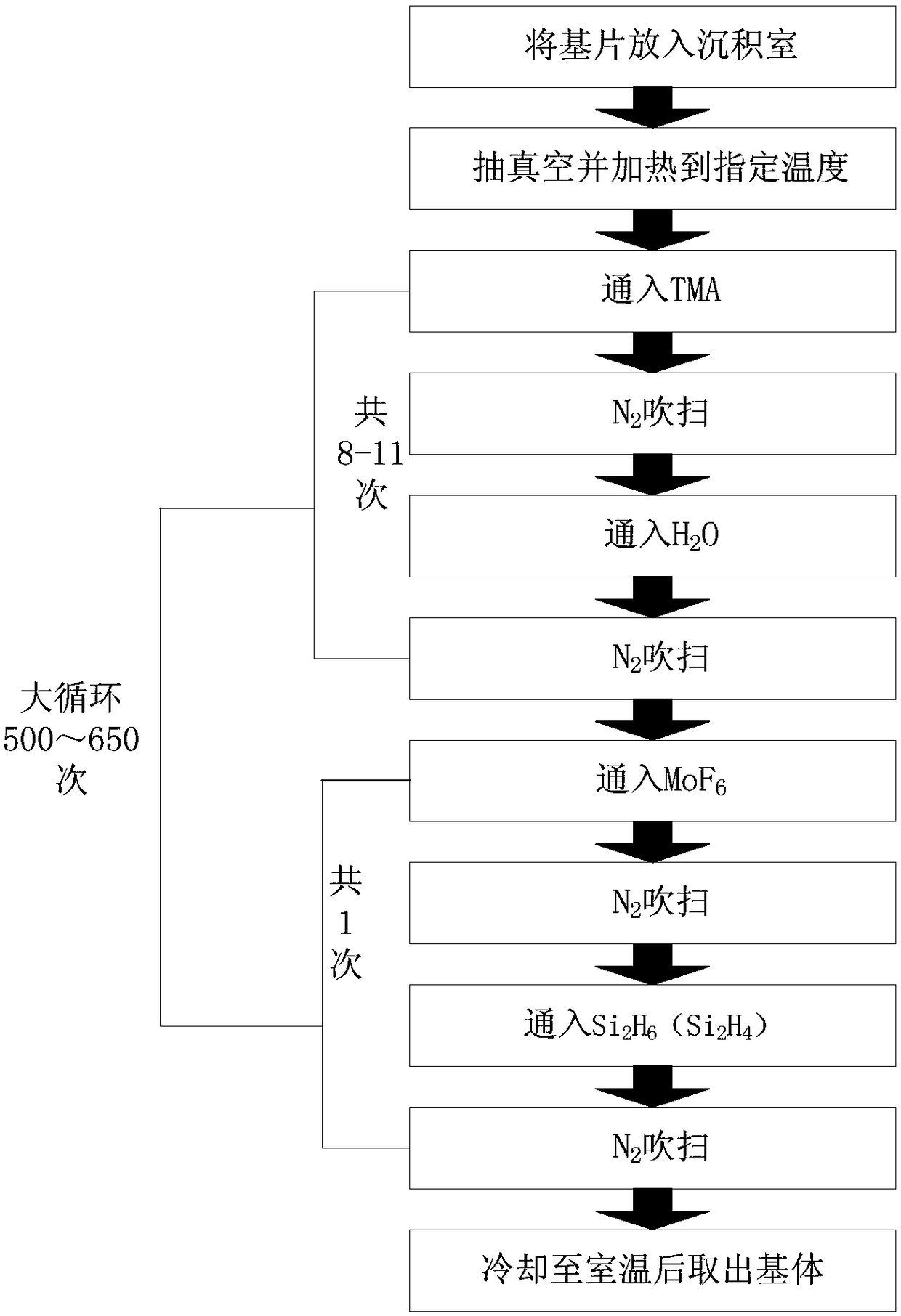

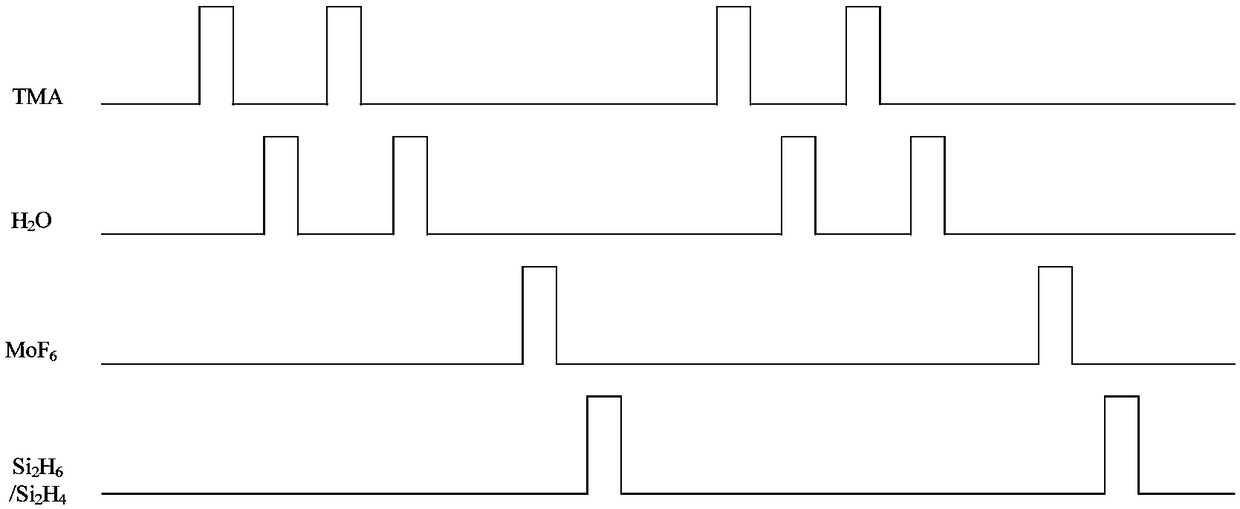

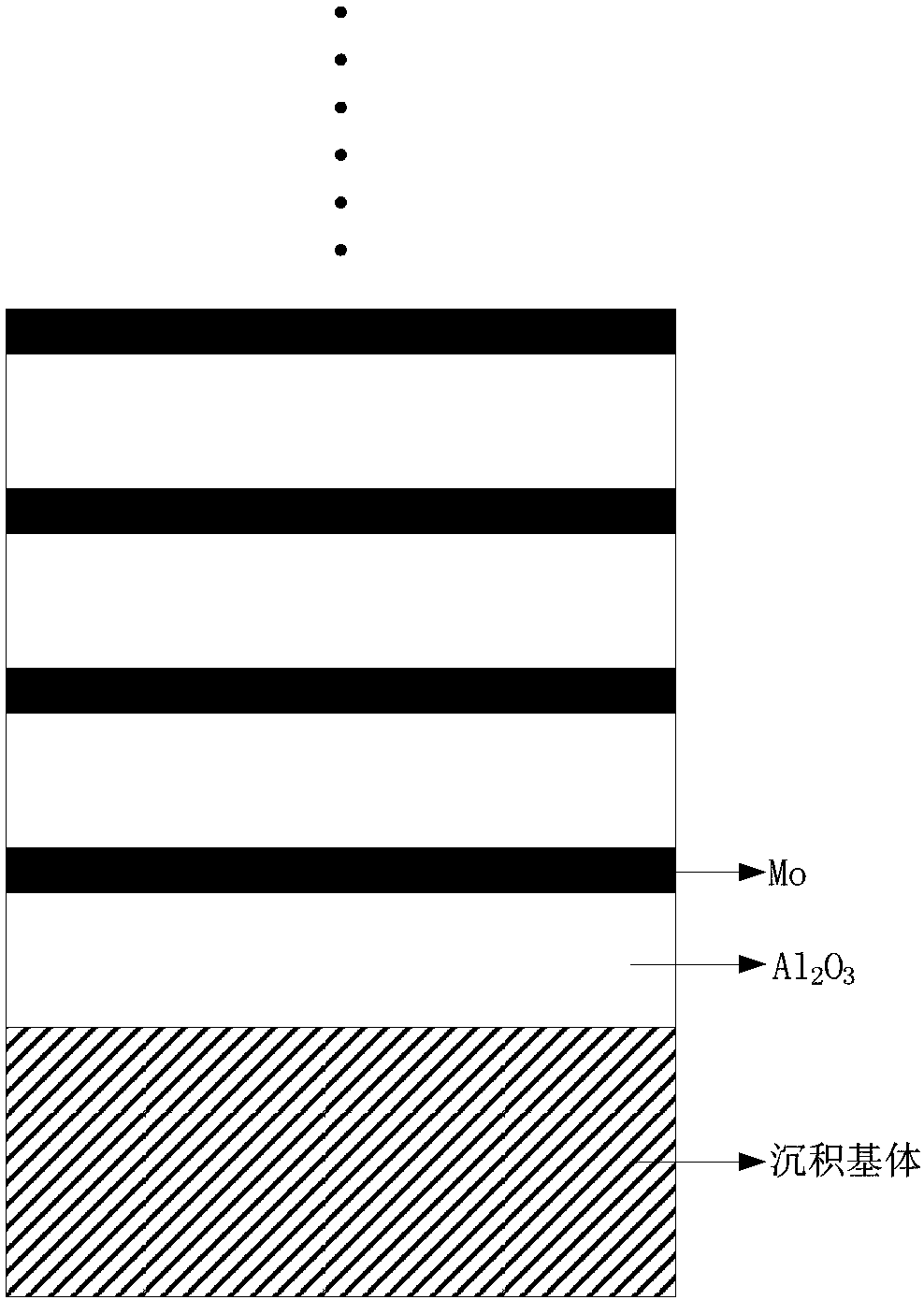

[0061] Put the substrate into the atomic layer deposition chamber and evacuate to 10 -2 Pa~10 -5 Pa, and the substrate is heated to 200°C to start Al 2 o 3 deposition, ie TMA / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 11 cycles, 1 Mo deposition, namely MoF 6 / N 2 / Si 2 h 6 (Si 2 h 4 ) / N 2 =(0.5s / 5s / 0.5s / 5s), 11 times Al 2 o 3 The deposition cycle and one Mo deposition constitute a large cycle. The deposition is stopped after 500 large cycles. After the temperature of the deposition chamber drops to room temperature, the deposition chamber is opened and the deposited Mo-doped Al 2 o 3 substrate of the film.

Embodiment 2

[0063] Put the substrate into the atomic layer deposition chamber and evacuate to 10 -2 Pa~10 -5 Pa, and the substrate is heated to 200°C to start Al 2 o 3 deposition, ie TMA / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 10 cycles, Mo deposition is carried out once, that is, M O f 6 / N 2 / Si 2 h 6 (Si 2 h 4 ) / N 2 =(0.5s / 5s / 0.5s / 5s), 10 Al2O3 deposition cycles and 1 Mo deposition is a large cycle, stop deposition after 550 large cycles, wait until the temperature of the deposition chamber drops to room temperature, open the deposition chamber, remove the deposited Mo-doped Al 2 o 3 substrate of the film.

Embodiment 3

[0065] Put the substrate into the atomic layer deposition chamber and evacuate to 10 -2 Pa~10 -5 Pa, and the substrate is heated to 200°C to start Al 2 o 3 deposition, ie TMA / N 2 / H2O / N 2 =(0.1s / 3s / 0.1s / 3s), after 9 cycles, Mo deposition is carried out once, that is, M O f 6 / N 2 / Si 2 h 6 (Si 2 h 4 ) / N 2 =(0.5s / 5s / 0.5s / 5s), 9 times Al 2 o 3 The deposition cycle and 1 Mo deposition are 1 large cycle. After 600 large cycles, the deposition is stopped. After the temperature of the deposition chamber drops to room temperature, the deposition chamber is opened, and the deposited Mo-doped Al 2 o 3 substrate of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com