A device and method for removing residual water on the surface of roller quenching of plate and strip

A technology for removing devices and plates and strips, which is applied in the direction of quenching devices, furnaces, furnace types, etc., can solve the problems of complex heat transfer forms, difficult to effectively control the heat transfer process, and affect the jet impact heat transfer process, so as to improve the cooling intensity and uniformity, improved controllability and uniformity, and improved cooling intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

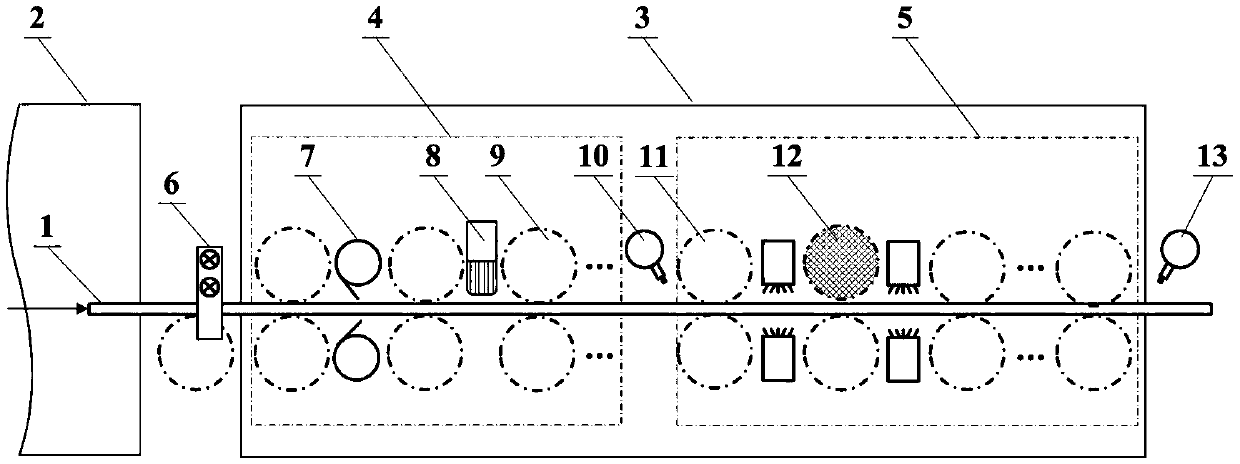

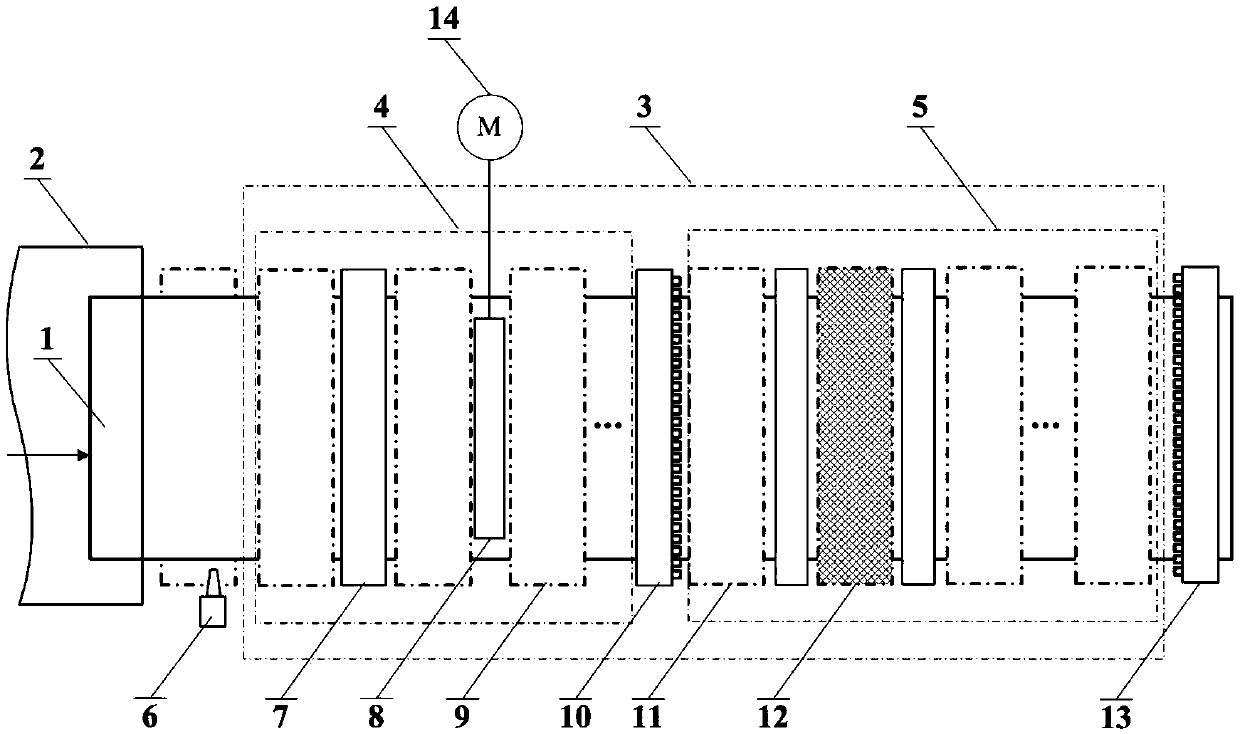

[0031] This embodiment provides a specific embodiment of the device for removing residual water on the surface of a plate and strip roller quenching of the present invention, such as figure 1 , 2 As shown, choose 80mm thick, 2500mm wide, 8m long plate and strip as an example to illustrate the implementation process. After the head of the plate and strip 1 leaves the heat treatment furnace 2 and reaches the front end of the high-pressure cooling zone 4 of the roller quenching machine 3, the air blowing nozzle 6 at the front of the high-pressure cooling zone is opened, the air injection pressure is 0.4-0.6MPa, and the air injection flow rate is 10Nm 3 / min, air injection time 2min, when the tail of the plate and strip 1 leaves the front end of the high-pressure cooling zone 4 of the roller quenching machine 3, the air blowing nozzle 6 at the front of the high-pressure cooling zone is closed. When the head of the strip 1 reaches the end of the high-pressure cooling zone 4 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com