A kind of two-component mirror glass ink and its application method

A glass ink, two-component technology, applied in the direction of ink, applications, household appliances, etc., can solve the problems of failing to pass the ultrasonic test, difficult to meet the set requirements, not suitable for large-area printing, etc., to avoid glass bursting, Not easy to fade, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

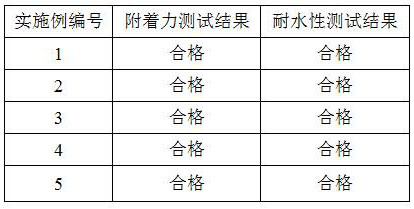

Examples

Embodiment 1

[0024] Preparation of component A: Add 50% varnish, 50% mirror silver paste, and 0% pigment into the mixer, control the stirring speed to 150r / min, and stir evenly to prepare component A.

[0025] The preparation method of the varnish is: adding 80% isophorone, 10% modified cellulose ether, 5% Aofan SL-95 solid resin, and 5% zinc ricinoleate in mass percentages In the stirrer, control the stirring speed to 1200 r / min, and stir at 25°C for 120 min to prepare the varnish.

[0026] The preparation method of the modified cellulose ether is as follows: adding 51% water-soluble cellulose ether, 2% sodium hydroxide, and 20% deionized water into a reaction kettle equipped with a stirring device, and controlling The stirring speed is 350r / min. After reacting at 25°C for 30min, add 22% tetramethylsilane and 5% sodium lignosulfonate by mass respectively, then raise the temperature to 65°C, continue the reaction for 2h, and then depressurize Distillation to obtain modified cellulose ethe...

Embodiment 2

[0029]Preparation of Component A: Add 60% varnish, 35% mirror silver paste, and 5% titanium dioxide to the mixer, control the stirring speed to 150r / min, and stir evenly to prepare Component A .

[0030] The preparation method of the varnish is: adding 83% isophorone, 5% modified cellulose ether, 8% Aofan SL-95 solid resin, and 4% zinc ricinoleate in mass percentages In the stirrer, control the stirring speed to 1200 r / min, and stir at 25°C for 120 min to prepare the varnish.

[0031] The preparation method of the modified cellulose ether is as follows: add water-soluble cellulose ether, 6% sodium hydroxide, and 10% deionized water in a mass percentage of 56% respectively in a reactor equipped with a stirring device, and control The stirring speed is 350r / min. After reacting at 25°C for 30min, add 20% tetramethylsilane and 8% sodium lignosulfonate by mass respectively, then raise the temperature to 65°C, continue the reaction for 2h, and then depressurize Distillation to obt...

Embodiment 3

[0034] Preparation of Component A: Add 58% varnish, 32% mirror silver paste, and 10% carbon black to the mixer, control the stirring speed to 150r / min, and stir evenly to prepare Component A .

[0035] The preparation method of the varnish is: adding 82% isophorone, 8% modified cellulose ether, 5% Aofan SL-95 solid resin, and 5% zinc ricinoleate in mass percent In the stirrer, control the stirring speed to 1200 r / min, and stir at 25°C for 120 min to prepare the varnish.

[0036] The preparation method of the modified cellulose ether is as follows: add water-soluble cellulose ether, 2% sodium hydroxide, and 18% deionized water in a reaction kettle equipped with a stirring device, and control The stirring speed is 350r / min. After reacting at 25°C for 30min, add 18% tetramethylsilane and 10% sodium lignosulfonate by mass respectively, then raise the temperature to 65°C, continue the reaction for 2h, and then depressurize Distillation to obtain modified cellulose ether.

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com