Preparation method for producing slow-release flower fertilizer by using waste plastic granules

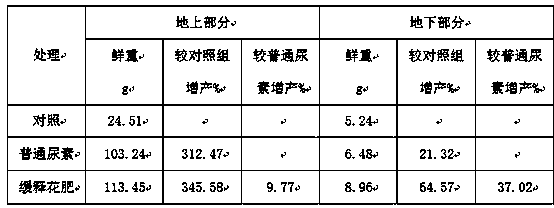

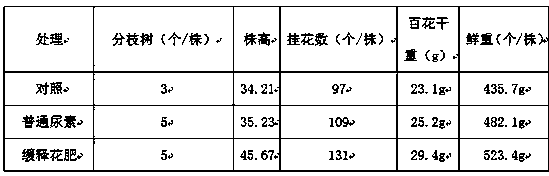

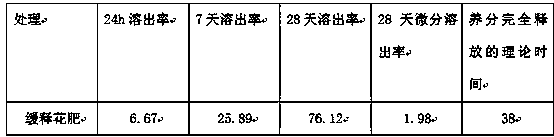

A technology for waste plastics and granules, which is applied to the preparation field of waste plastic granules to produce slow-release flower fertilizer, can solve the problems of polluted farmland, high production cost, complicated preparation process, etc., and achieves the effects of less ash, low production cost, and sturdy stems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method for producing slow-release flower fertilizer from waste plastic granules, which is made of the following raw materials in parts by weight: 30 parts of animal manure, 20 parts of waste plastic granules, 20 parts of urea, 5 parts of peanut shells, 15 parts of egg shells, and 20 parts of fruit peel waste 20 parts of potato waste, 10 parts of plant ash, 5 parts of binder, 3 parts of waste oil, and 1 part of controllable degradation agent.

[0022] A preparation method for producing slow-release flower fertilizer from waste plastic granules, comprising the following steps: (1) respectively mixing animal feces, waste plastic granules, urea, peanut shells, egg shells, fruit peel waste, potato waste, plant ash, and After the agent, waste oil, and compression molding are carried out, the pyrolysis reaction is continued, and after cooling, it is pulverized into a powder for later use; (2) plant ash and 0.1mol / L sulfuric acid solution are prepared into a mixed ...

Embodiment 2

[0029] A preparation method for producing slow-release flower fertilizer from waste plastic granules, which is made of the following raw materials in parts by weight: 40 parts of animal manure, 30 parts of waste plastic granules, 10 parts of urea, 5 parts of peanut shells, 10 parts of egg shells, and 10 parts of fruit peel waste 10 parts of potato waste, 10 parts of plant ash, 5 parts of binder, 3 parts of waste oil, and 1 to 3 parts of controllable degradation agent.

[0030]A preparation method for producing slow-release flower fertilizer from waste plastic granules, comprising the following steps: (1) respectively mixing animal feces, waste plastic granules, urea, peanut shells, egg shells, fruit peel waste, potato waste, plant ash, and agent, gutter oil, controllable degradation agent, after compression molding, continue to carry out pyrolysis reaction, after cooling, pulverize into powder again for later use; Prepare a mixed solution, microwave reaction at 40°C for 10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com