Fertilizer containing activated water and preparation and application method thereof

A technology of active water and fertilizer, applied in fertilization methods, applications, inorganic fertilizers, etc., can solve the problems of increasing fertilizer efficiency, and achieve the effects of increasing fruit, early harvest, and promoting photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

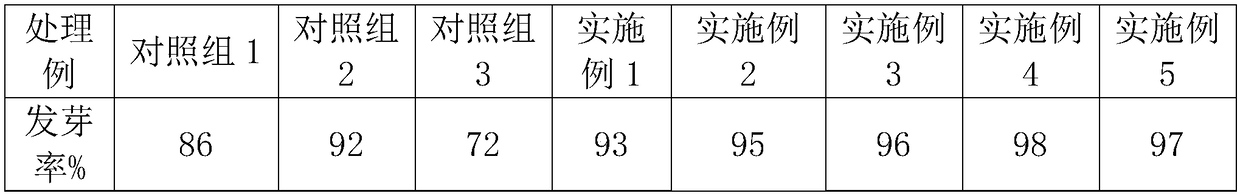

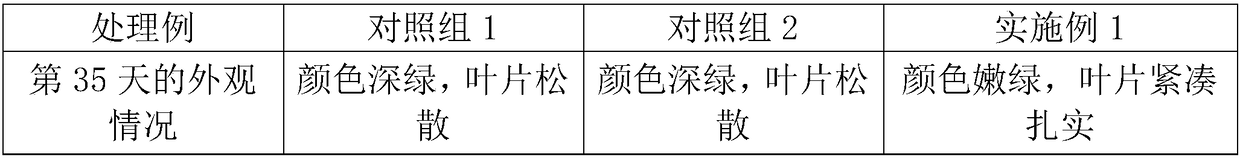

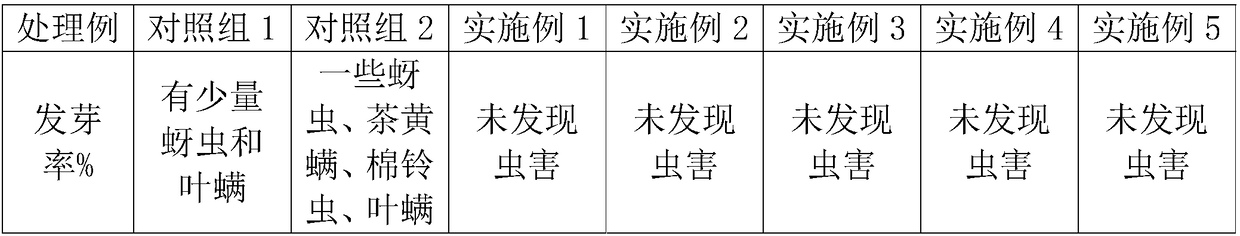

Examples

Embodiment 1

[0034] Weigh 18.12g of component A and 52.95g of active water and mix evenly, 6.14g of component B and 18.91g of active water, mix evenly, mix 0.02g of component C and 3.78g of active water, and then stir the three evenly Mix together. Wherein, Component A contains 7.94g silicon fertilizer (silicon dioxide), 2.02g magnesium fertilizer (magnesium chloride), 3.35g titanium fertilizer (nano-titanium dioxide), 19.5g calcium fertilizer (calcium magnesium phosphate fertilizer) and 2.4g potassium fertilizer (sulfuric acid Potassium), wherein, contain 2.34g fertilizer tackifier in the component B, 1.39g organic colloid, 2.09g polymer dispersant (polyvinyl alcohol), 0.01g advanced agricultural silver agent (nano-silver halide colloid), 0.5g selenium Source material (selenourea formaldehyde); Wherein, 0.02g in component C, component C is trace element Fe+Cu+Mn+Zn+B+Mo, and each component mass ratio is Zn:Mn:B:Mo:Cu: Fe=16:8:2.5:1.5:1.5:1.

Embodiment 2

[0036]Weigh 19.5g of component A and 51.41g of active water and mix evenly, 6.86g of component B and 18.36g of active water, mix evenly, mix 0.2g of component C and 3.67g of active water, and then stir the three evenly Mix together, wherein, comprise 8g silicon fertilizer (silicon dioxide) in the component A, 2.5g magnesium fertilizer (magnesium chloride), 3.5g titanium fertilizer (nano-titanium dioxide), 2.5g calcium fertilizer (calcium magnesium phosphate fertilizer) and 3g potash fertilizer ( Potassium sulfate), wherein, comprise 2.5g fertilizer viscosifier in the component B, 2.5g macromolecule dispersant (polyvinyl alcohol), 0.01g advanced agricultural silver agent (nano-silver halide colloid) and 0.35g selenium source material (selenium urea formaldehyde). Wherein, component C is trace element Fe+Cu+Mn+Zn+B+Mo, and the mass ratio of each component is Zn:Mn:B:Mo:Cu:Fe=16:8:2.5:1.5:1.5:1.

Embodiment 3

[0038] Weigh 25g of component A and 45.47g of active water and mix evenly, 10g of component B and 16.24g of active water, mix evenly, mix 0.05g of component C and 3.25g of active water, and then mix the three evenly in the Together, wherein, in component A, comprise 10g silicon fertilizer (silicon dioxide), 3g magnesium fertilizer (magnesium chloride), 4g titanium fertilizer (nano-titanium dioxide), 5g calcium fertilizer (calcium magnesium phosphate fertilizer), 3g potash fertilizer (potassium sulfate), wherein , Component B contains 4.1g fertilizer tackifier, 2.8g organic colloid, 0.02g high-grade agricultural silver agent (nano-silver halide colloid), 0.08g selenium source material (selenourea formaldehyde); wherein, component C is trace element Fe+Cu+Mn+Zn+B+Mo, the mass ratio of each component is Zn:Mn:B:Mo:Cu:Fe=16:8:2.5:1.5:1.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com