Base fertilizer specially used for figs and preparation method thereof

A production method and technology for figs, applied in inorganic fertilizers, applications, magnesium fertilizers, etc., can solve problems such as late start, and achieve the effects of improving anoxic state, improving yield and quality, and promoting metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

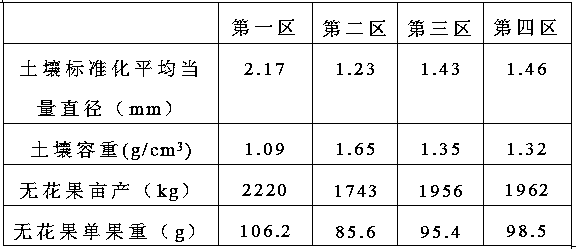

Image

Examples

Embodiment 1

[0016] A special base fertilizer for figs, comprising the following components in parts by weight: 600 parts of cattle and sheep manure, 300 parts of methane residue, 80 parts of calcium magnesium phosphate fertilizer, 40 parts of nitrogen fertilizer, 25 parts of calcium peroxide, 15 parts of magnesium peroxide, sea foam 10 parts of stone powder, 15 parts of calcium carbide powder, 25 parts of sodium bentonite and 2 parts of organic fertilizer fermentation bacteria.

Embodiment 2

[0018] A special base fertilizer for figs, comprising the following components in parts by weight: 800 parts of cattle and sheep manure, 400 parts of methane residue, 100 parts of calcium magnesium phosphate fertilizer, 50 parts of nitrogen fertilizer, 30 parts of calcium peroxide, 20 parts of magnesium peroxide, sea foam 15 parts of stone powder, 20 parts of calcium carbide powder, 35 parts of sodium bentonite and 2.5 parts of organic fertilizer fermentation bacteria.

Embodiment 3

[0020] A special base fertilizer for figs, comprising the following components in parts by weight: 700 parts of cattle and sheep manure, 350 parts of methane residue, 90 parts of calcium magnesium phosphate fertilizer, 45 parts of nitrogen fertilizer, 28 parts of calcium peroxide, 18 parts of magnesium peroxide, sea foam 12 parts of stone powder, 18 parts of calcium carbide powder, 30 parts of sodium bentonite and 2.2 parts of organic fertilizer fermentation bacteria.

[0021] A kind of preparation method of base fertilizer special for fig, comprises the following steps:

[0022] S1. Mix the cattle and sheep manure and biogas residue in the above parts by weight and dry them at a temperature of 50-55° C. until the water content is 35%, and then crush the dried materials to a particle size of 3-5 mm to obtain a fermented material;

[0023] S2, in the fermented material of S1 gained, add the above-mentioned organic fertilizer fermenting agent of weight part and mix homogeneously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com