Comprehensive resource utilization method of electrolytic manganese slag and steel slag tailing mud

A technology of steel slag tailing sludge and electrolytic manganese slag is applied in the field of environmental engineering, which can solve the problems of huge energy consumption and lack of economy, and achieve the effect of solving the low comprehensive utilization rate and alleviating the shortage of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

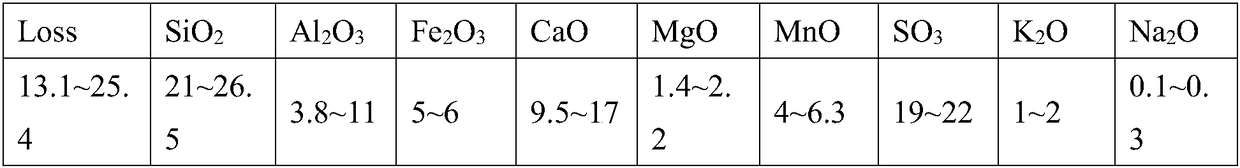

Image

Examples

Embodiment 1

[0038] An autoclaved aerated block produced by using electrolytic manganese slag and steel slag tailings, characterized in that the raw material components of the autoclaved aerated block and their weight percentages (in terms of dry weight of materials) are:

[0039]

[0040]

[0041] The measured moisture content of the raw materials is: 30% of the original electrolytic manganese slag, 15% of the original steel slag tailings, and 15% of the water-quenched blast furnace slag; the total water-cement ratio is 0.53.

[0042] Specific steps are as follows:

[0043] S1 mixed grinding

[0044] Weigh the original electrolytic manganese slag, original steel slag tailings, and water-quenched blast furnace slag according to the formula mass ratio, and add water with a total dry weight of 8% of the material to mix and grind for 45 minutes. The fineness reaches (0.045 square hole sieve residue) 14.9%. The pH value of the system was 10.5, and slurry A was prepared.

[0045] S2, ra...

Embodiment 2

[0064] An autoclaved aerated block produced by using electrolytic manganese slag and steel slag tailings, characterized in that the raw material components of the autoclaved aerated block and their weight percentages (in terms of dry weight of materials) are:

[0065]

[0066] The measured moisture content of the raw materials is: 28.5% of the original electrolytic manganese slag, 15% of the original steel slag tailings, and 12% of the water-quenched blast furnace slag; the total water-cement ratio is 0.53.

[0067] Specific steps are as follows:

[0068] S1 mixed grinding

[0069] Weigh the original electrolytic manganese slag, original steel slag tailings, and water-quenched blast furnace slag according to the formula mass ratio, and add water with a total dry weight of 9% of the material to mix and grind for 45 minutes. The fineness reaches (0.045 square hole sieve residue) 12.4%. The pH value of the system was 10.8, and slurry A was prepared.

[0070] S2, ratio measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com