Environment-friendly lightweight concrete and preparation method thereof

A lightweight concrete and environmentally friendly technology, applied in the field of concrete, can solve the problems of low resource utilization and energy waste, achieve low bulk density, save ground material resources, and reduce the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

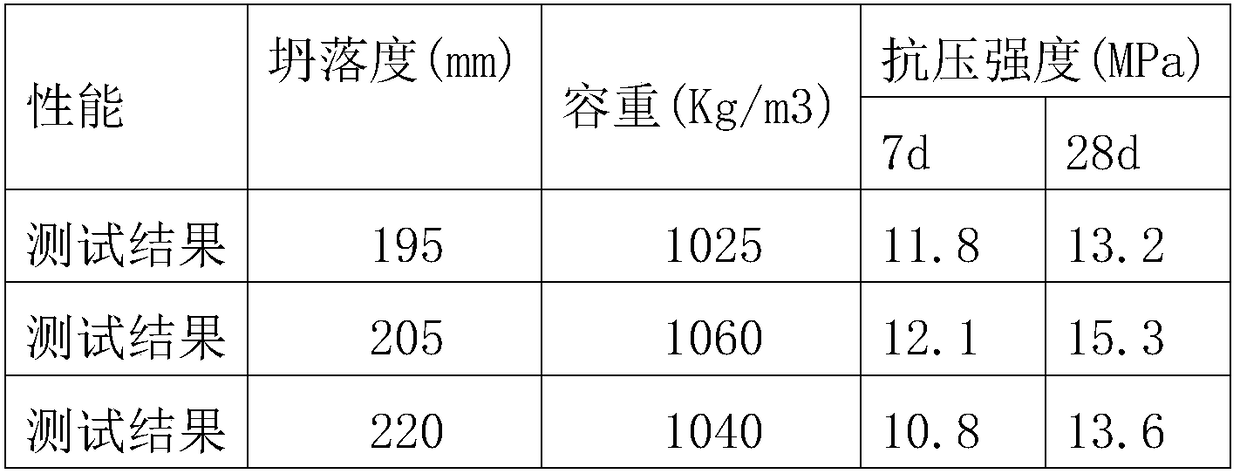

Examples

Embodiment 1

[0020] The invention discloses an environment-friendly lightweight concrete, which is prepared from the following components in parts by weight: 360 parts of cement, 120 parts of fly ash, 300 parts of slag, 150 parts of foamed ceramics, and 6 parts of polyphenylene particles , 180 parts of water, 12 parts of admixture, and 0.4 part of thickener.

[0021] The admixture adopts polycarboxylate high-performance water reducer.

[0022] The thickener adopts cellulose ether.

[0023] The foamed ceramics are waste ceramics.

[0024] The invention also discloses the preparation method of the above-mentioned environment-friendly lightweight concrete. The specific steps are as follows: according to the above-mentioned parts by weight, the foamed ceramics are pulverized, passed through 200 sieves to obtain ceramic powder, and then cement, fly ash, slag, ceramic Add the powder and polyphenylene particles into the mixer in turn, after mixing evenly, add 75% of the weighed water, stir for ...

Embodiment 2

[0026] The invention discloses an environment-friendly lightweight concrete, which is prepared from the following components in parts by weight: 400 parts of cement, 100 parts of fly ash, 100 parts of slag, 140 parts of foamed ceramics, and 5 parts of polystyrene particles , 200 parts of water, 13 parts of admixture, 0.35 parts of thickener.

[0027] The admixture adopts polycarboxylate high-performance water reducer.

[0028] The thickener adopts cellulose ether.

[0029] The foamed ceramics are waste ceramics.

[0030] The invention also discloses the preparation method of the above-mentioned environment-friendly lightweight concrete. The specific steps are as follows: according to the above-mentioned parts by weight, the foamed ceramics are pulverized, passed through 300 sieves to obtain ceramic powder, and then cement, fly ash, slag, ceramic Add the powder and polyphenylene particles into the mixer in turn, after mixing evenly, add 75% of the weighed water, stir for 1 mi...

Embodiment 3

[0032] The invention discloses an environment-friendly lightweight concrete, which is prepared from the following components in parts by weight: 420 parts of cement, 60 parts of fly ash, 280 parts of slag, 50 parts of foamed ceramics, and 7 parts of polystyrene particles , 160 parts of water, 9 parts of admixture, and 0.4 part of thickener.

[0033] The admixture adopts polycarboxylate high-performance water reducer.

[0034] The thickener adopts cellulose ether.

[0035] The foamed ceramics are waste ceramics.

[0036] The invention also discloses the preparation method of the above-mentioned environment-friendly lightweight concrete. The specific steps are as follows: according to the above-mentioned parts by weight, the foamed ceramics are pulverized, passed through 200 sieves to obtain ceramic powder, and then cement, fly ash, slag, ceramic Add the powder and polyphenylene particles into the mixer in turn, after mixing evenly, add 75% of the weighed water, stir for 5 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com