A kind of normal temperature synthetic early-strength type liquid alkali-free accelerator and preparation method thereof

A room temperature synthesis, early strength technology, applied in the field of cement concrete additives, can solve the problems of decreased concrete strength and durability, unfavorable large-scale popularization and large loss of strength of accelerators, etc., and achieves reduced possibility and good economic benefits. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

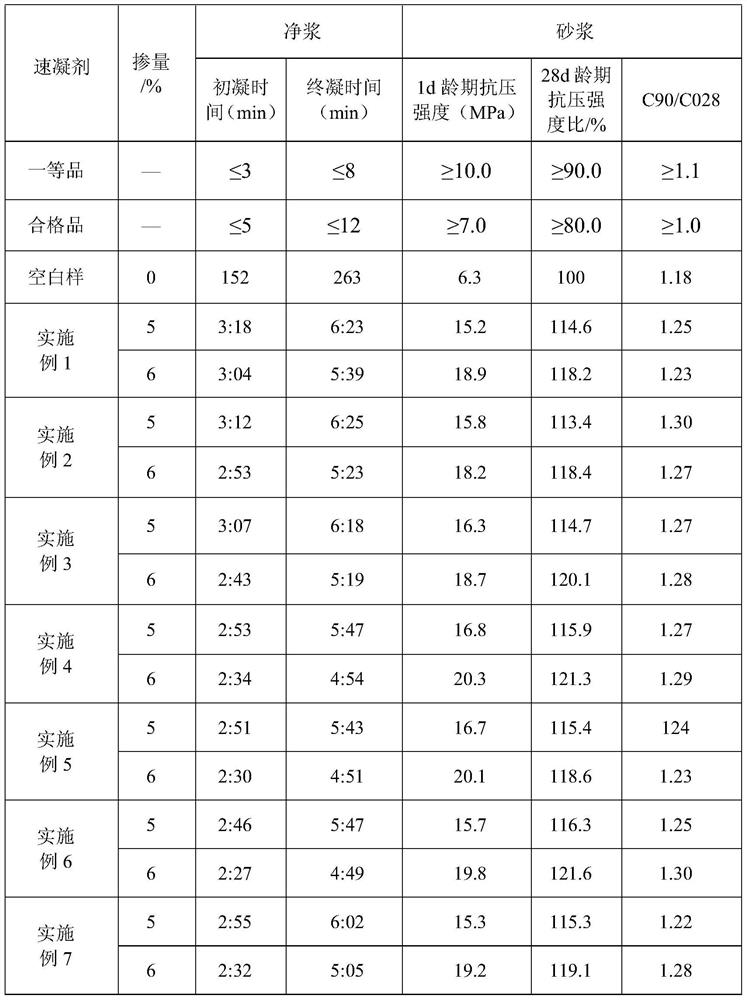

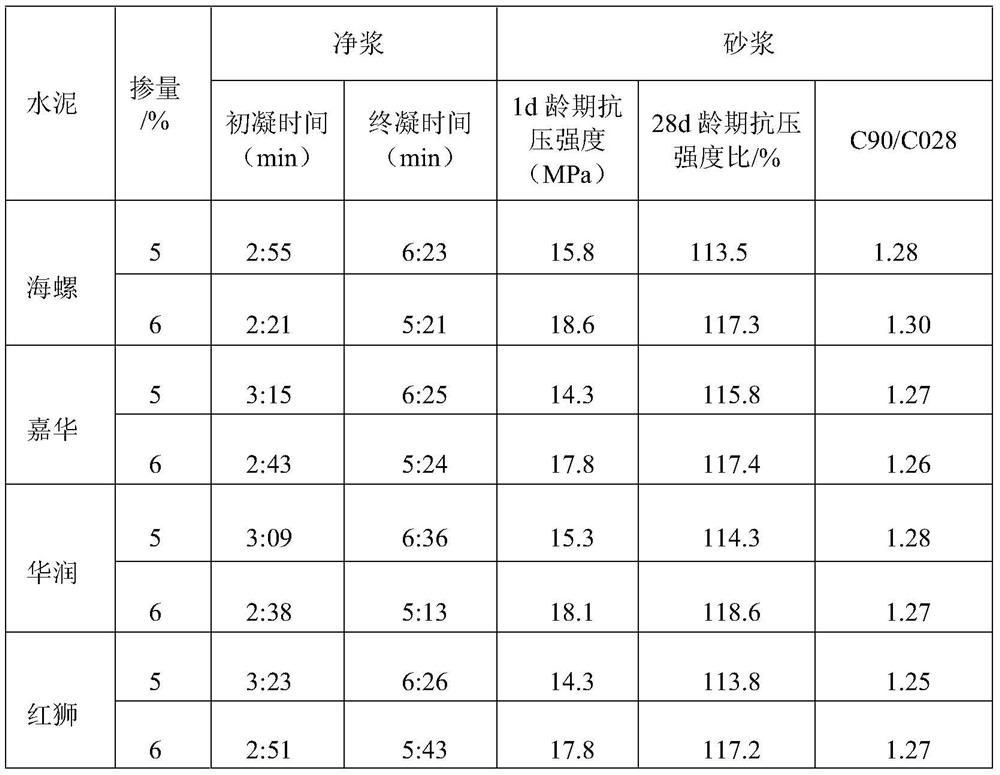

Examples

Embodiment 1

[0023] Prepare a normal temperature synthetic early-strength type liquid alkali-free accelerator, the specific steps are as follows:

[0024] A. Add 30 parts of water and 10 parts of diethanolamine (purity>99%) to 60 parts of polyaluminum sulfate (Al 2 o 3 content 19%), stirred at room temperature until the polyaluminum sulfate dissolves to form a stable transparent solution, that is, the modified polyaluminum sulfate solution;

[0025] B, take each raw material by following each component: modified polyaluminum sulfate solution 60%, graphene oxide (layered graphene oxide below 5 layers) 3%, stabilizer (citric acid) 1%, performance regulator 5%, water 31%;

[0026] C. Add 3 parts of graphene oxide and 31 parts of water into 60 parts of modified polyaluminum sulfate solution for ultrasonic dispersion for 20 minutes to obtain a stable transparent solution;

[0027] D. Add 5 parts of performance modifier to the stable transparent solution obtained above, stir at room temperatu...

Embodiment 2

[0029] Prepare a normal temperature synthetic early-strength type liquid alkali-free accelerator, the specific steps are as follows:

[0030] A. Add 30 parts of water and 15 parts of diethanolamine to 55 parts of polyaluminum sulfate (Al 2 o 3 content 18%), stirred at room temperature until the polyaluminum sulfate dissolves to form a stable transparent solution, that is, the modified polyaluminum sulfate solution;

[0031] B, each raw material is weighed according to the following components: modified polyaluminum sulfate solution 65%, graphene oxide 2%, stabilizer (ethylenediaminetetraacetic acid) 1%, performance regulator 4%, water 28%;

[0032] C. Add 2 parts of graphene oxide and 28 parts of water into 65 parts of modified polyaluminum sulfate solution for ultrasonic dispersion for 20 minutes to obtain a stable transparent solution;

[0033] D. Add 4 parts of performance modifier to the stable transparent solution obtained above, stir for 1 hour at room temperature to e...

Embodiment 3

[0035] Prepare a normal temperature synthetic early-strength type liquid alkali-free accelerator, the specific steps are as follows:

[0036] A. Add 40 parts of water and 10 parts of diethanolamine to 50 parts of polyaluminum sulfate (Al 2 o 3 content 19%), stirred at normal temperature until the polyaluminum sulfate dissolves to form a stable transparent solution, that is, the modified polyaluminum sulfate solution;

[0037] B, each raw material is weighed according to the following components: modified polyaluminum sulfate solution 70%, graphene oxide 1%, stabilizer (citric acid) 2%, performance modifier 3%, water 24%;

[0038] C. Add 1 part of graphene oxide and 24 parts of water into 70 parts of modified polyaluminum sulfate solution for ultrasonic dispersion for 20 minutes to obtain a stable transparent solution;

[0039] D. Add 3 parts of performance modifier to the stable transparent solution obtained above, stir at room temperature for 1 hour to ensure its full compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com