Preparation method of titanate-modified nano cerium oxide/polyurethane composite paint

A technology of nano-cerium oxide and composite coatings, applied in the field of coatings, to achieve good corrosion resistance and aging resistance, good storage stability, and not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

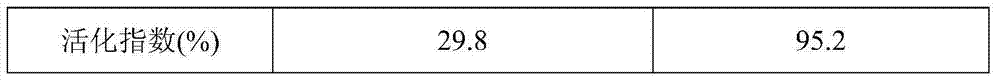

Embodiment 1

[0055] (1.1) Prepare raw materials according to the weight of the following components:

[0056] Nano cerium oxide 10kg;

[0057] NDZ-102 titanate coupling agent 0.2kg;

[0058] Mixed solvent (water: ethanol = 1:9) 89.8kg;

[0059] (1.2) First put 10kg of nano-cerium oxide powder into the high-speed disperser, then dilute it with 89.8kg of mixed solvent (water:ethanol=1:9), start the high-speed disperser, stir fully, and measure the pH value of the solution. The speed of the high-speed disperser is set at 600-1000 rpm, and the dispersion time is 20 minutes;

[0060] (1.3) Pour the mixture in step (1.2) into a three-necked flask, add 0.2kg of NDZ-102 titanate coupling agent, raise the temperature to 85°C, mix, stir and reflux for 5 hours, and test its pH value;

[0061] (1.4) Wash the pH value of the mixture prepared in step (1.3) with deionized water until it is consistent with the pH value of the mixture in step (1.2), filter the nanopowder, and wash the obtained powder wi...

Embodiment 2

[0092] (2.1) Prepare component 1. According to the weight percentage, component 1 includes the content of the following components: NDZ-102 titanate coupling agent modified nano-cerium oxide powder 2%;

[0093] Hydroxy acrylic resin 60%;

[0094] Auxiliary 5%;

[0095] Solvent 33%;

[0096] First mix NDZ-102 titanate coupling agent modified nano-cerium oxide powder, hydroxyacrylic resin, additives and solvent in a ratio of 2:60:5:33, then put it into a high-speed ball mill to achieve uniform mixing, start high-speed A ball mill. The speed of the high-speed ball mill is set at 200 rpm, and the ball milling time is 4 to 6 hours. After high-speed dispersion, component 1 of the NDZ-102 titanate coupling agent modified nano cerium oxide / polyurethane composite coating is obtained.

[0097] (2.2) Prepare component 2. According to weight percentage, component 2 includes the content of the following components:

[0098] Solvent 0~75%;

[0099] Curing agent 25~100%;

[0100] Add th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com