Preparation method of high-specific surface area nitrogen-rich classified porous carbon electrode material for supercapacitor

A high specific surface area, supercapacitor technology, applied in hybrid capacitor electrodes, chemical instruments and methods, carbon compounds, etc., to achieve simple process, low energy consumption, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

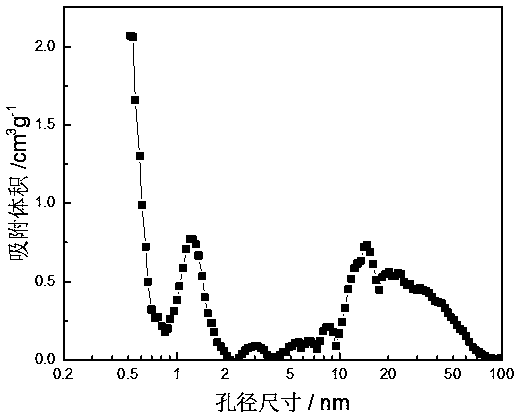

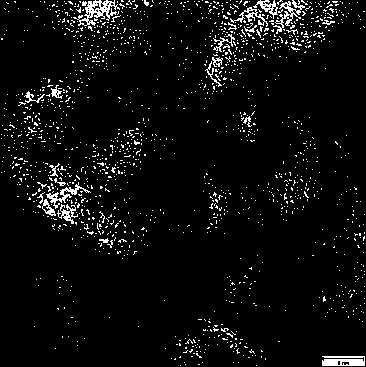

[0020] Take 25g of ethylenediaminetetraacetic acid disodium zinc salt and carbonize it at 700°C for 10 h under nitrogen atmosphere. The carbonized product is washed with 0.5 mol / L hydrochloric acid and water in sequence to prepare porous carbon. The nitrogen adsorption and desorption test shows that the specific surface area of the activated carbon material is 1530m 2 g -1 , pore volume 1.23 cm 3 g -1 , Mesoporosity is 50.5%. The pore size distribution curve is as figure 1 As shown, it shows that the pore size of the prepared carbon material contains micropores of 1-2nm and mesopores of 10-30nm. TEM as figure 2 As shown, abundant mesopores and micropores can be observed. XPS test nitrogen element distribution such as image 3 As shown, the material has a nitrogen content of 7.46%. The above materials were mixed according to the ratio of active material: acetylene black: PTFE = 85:10:5 to prepare electrode sheets, at 6 mol L -1 Two-electrode constant-current charge...

Embodiment 2

[0022] Take 30g of ethylenediaminetetraacetic acid disodium zinc salt and carbonize it at 850°C for 2 hours under the atmosphere of argon and nitrogen mixed gas volume ratio (1:1). The carbonized product was washed with 3 mol / L nitric acid and water in sequence to prepare porous carbon. The specific surface area of the activated carbon material is 2268m 2 g -1 , pore volume 2.6 cm 3 g -1 , the mesoporosity is 53.4%, and the nitrogen content is 6.71%. According to the test method of Example 1, when its current density is 0.1 A / g, the specific capacitance is calculated from the discharge curve up to 330F g -1 , the current density increased to 50 A g -1 , the specific capacitance still maintains 270 F g -1 , indicating that it has both high specific capacity and excellent rate capability.

Embodiment 3

[0024] Take 40g of ethylenediaminetetraacetic acid disodium zinc salt and carbonize it at 1000°C for 1h under an argon atmosphere. The carbonized product is washed with mixed acid of 2mol / L hydrochloric acid and 1mol / L sulfuric acid, and washed with water to prepare porous carbon. The specific surface area of the porous carbon material is 2680m 2 g -1 , pore volume 3.0 cm 3 g -1 , The mesoporosity is 59.4%. Nitrogen content 2.23%. According to the test method of Example 1, when its current density was 0.1 A / g, the specific capacitance was calculated from the discharge curve up to 326F g -1 , the current density increased to 50 A g -1 , the specific capacitance still remains 289 F g -1 , its specific capacity and rate performance are outstanding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com