Method for preparing hollow micro-nano carbon spheres from lignin by means of microwave-assisted heating

A microwave-assisted, lignin technology, applied in the field of waste resource utilization, can solve the problems of difficult to control morphology, poor process controllability of carbon materials, complex lignin structure, etc., and achieve excellent electrical conductivity, good thermal stability, The effect of high strength to weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Taking alkali lignin as an example to introduce the implementation process of the present invention is as follows:

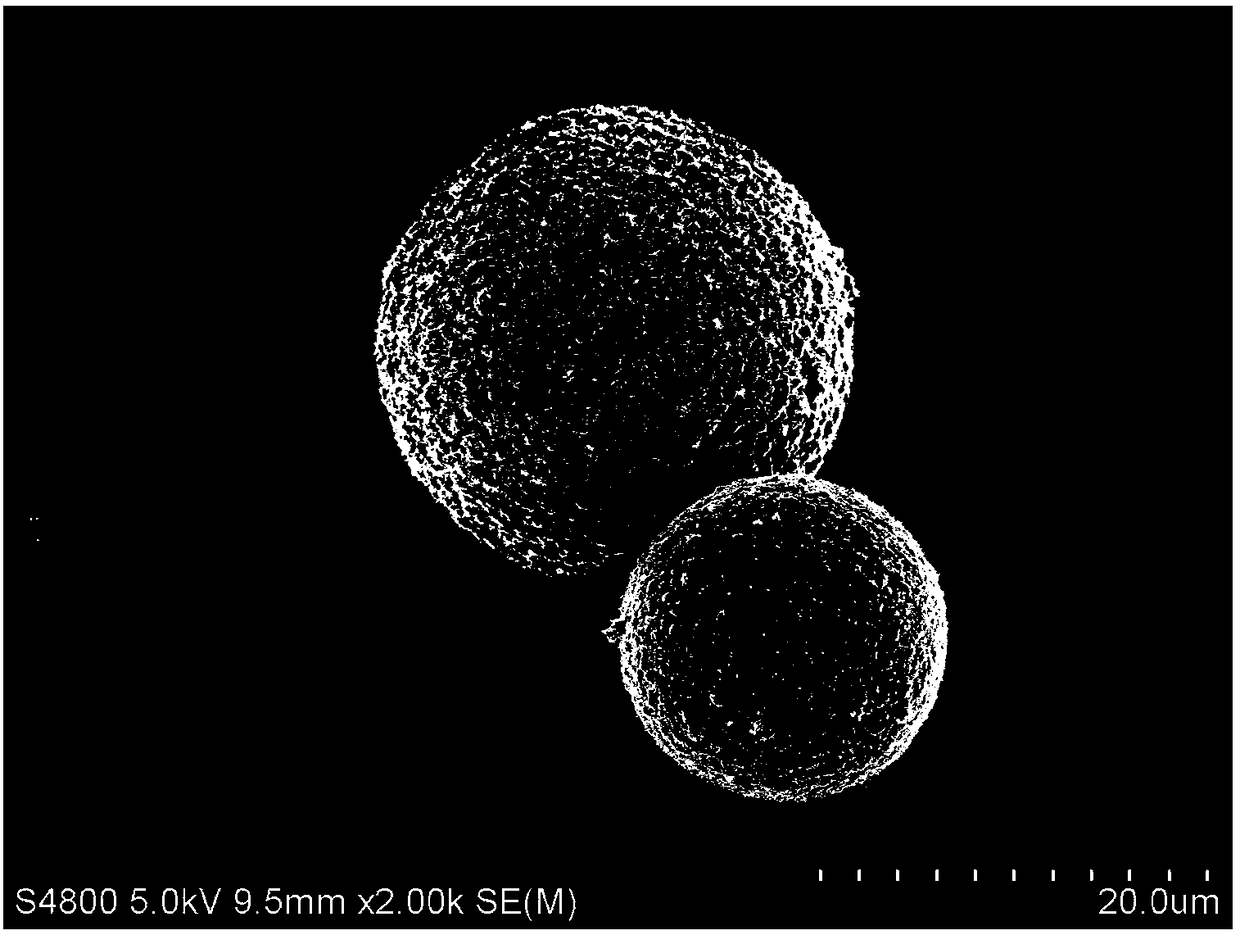

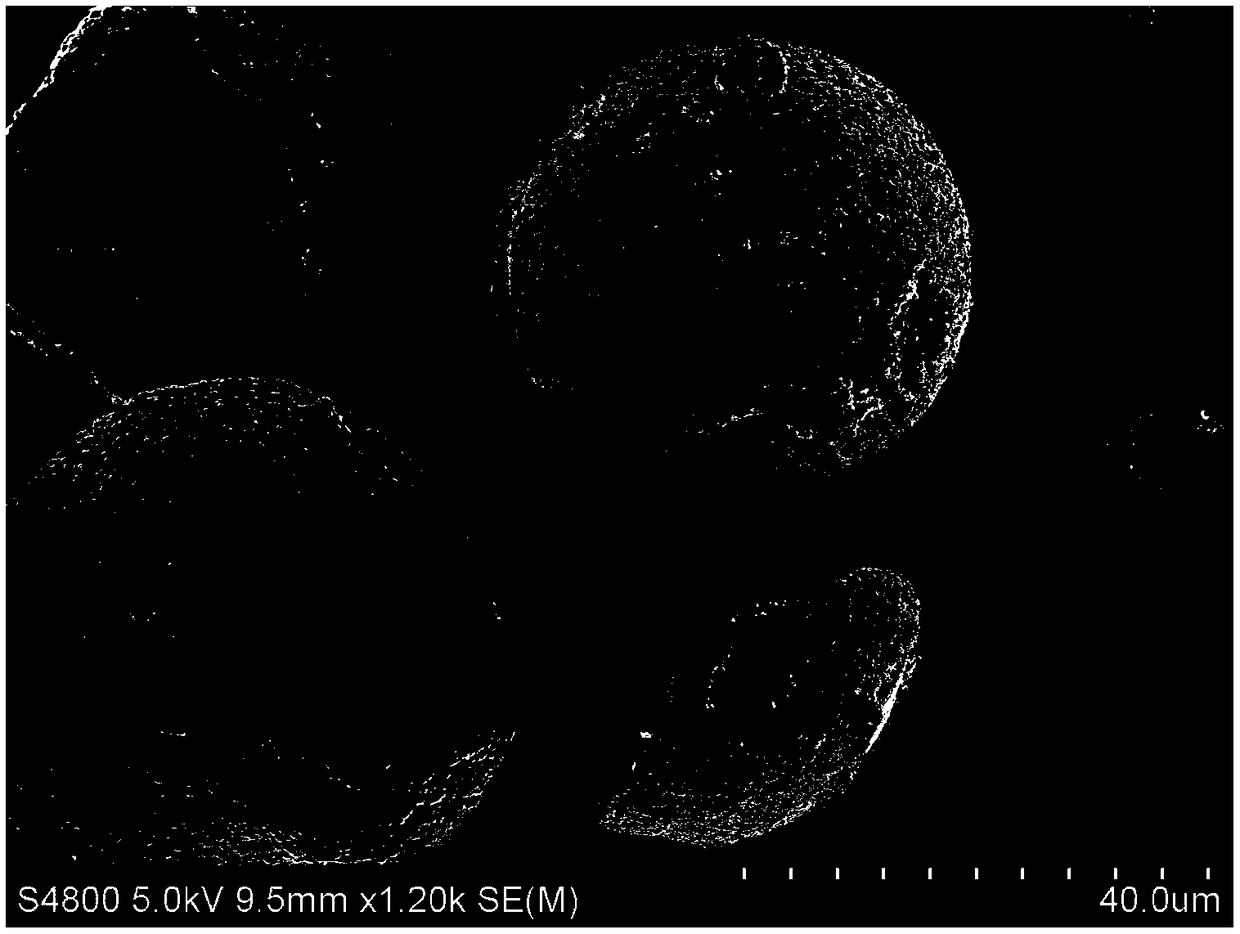

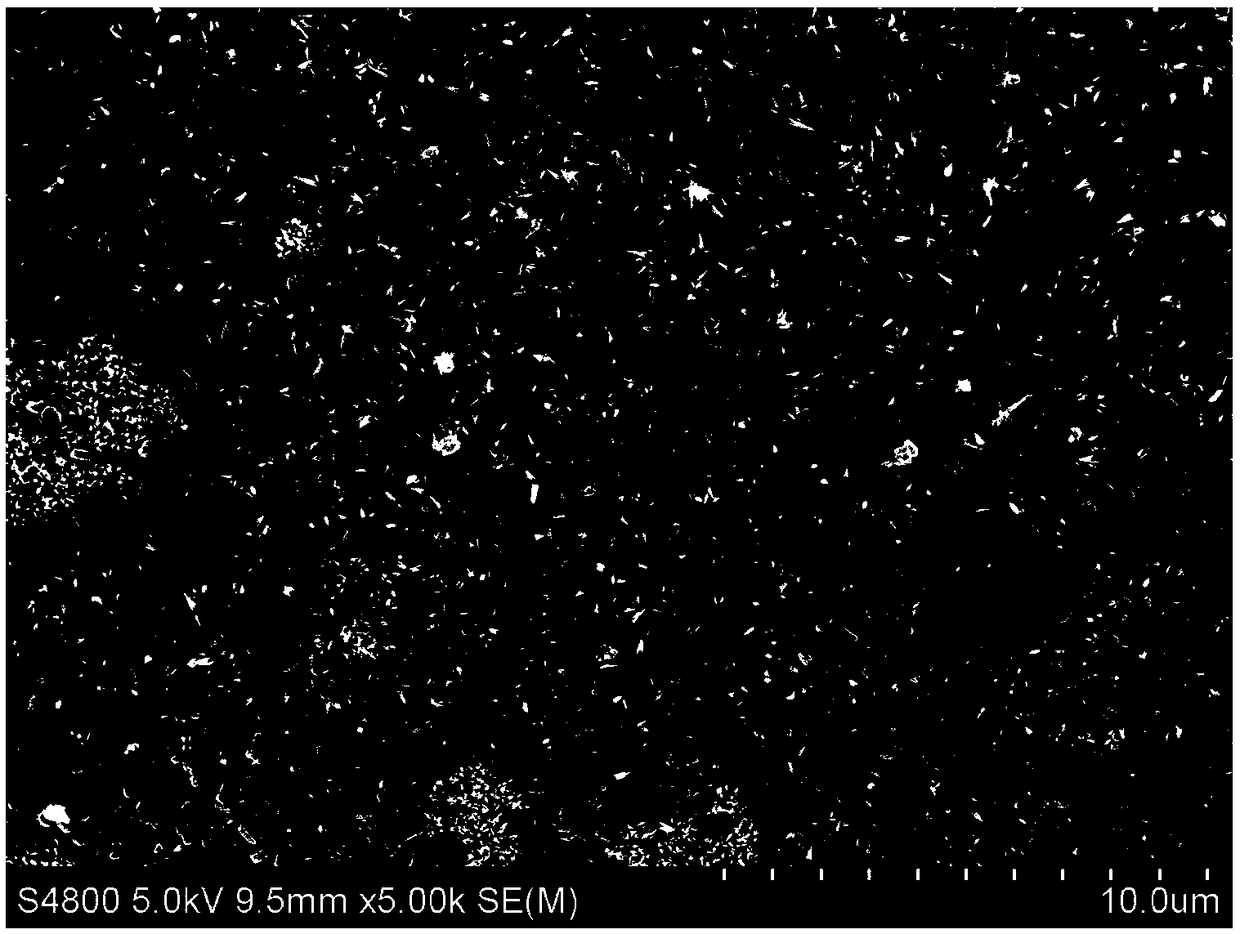

[0031] Put 10 grams of lignin with a particle size of 10-150 μm in a microwave reactor, and then pass 400mL / min nitrogen gas for 20 minutes to eliminate the air in the microwave reaction system, then turn on the microwave reactor for microwave-assisted heating, and the microwave frequency is 2.45 GHz, the microwave power is 800W, and the corresponding heating rate is 50°C / min. After the temperature rises to 350°C, adjust the microwave power to 300W, and the corresponding heating rate is 10°C / min, raise the temperature to 600°C, keep warm for 60 minutes, and then shut down Microwave reactor, when the temperature in the system drops below 150°C, turn off the nitrogen, and sieve the obtained solid product through a 12500-mesh filter. The solid product that passes through the filter is hollow carbon nanospheres, and the solid product that does not pass through...

Embodiment 2

[0034] Taking lignosulfonate as an example to introduce the implementation process of the present invention is as follows:

[0035] Put 10 grams of lignin with a particle size of less than 90 μm in a microwave reactor, and then pass 1000 mL / min of argon gas for 10 minutes to remove the air in the microwave reaction system, then turn on the microwave reactor for microwave-assisted heating, and the microwave frequency is 2.45 GHz , the microwave power is 2000W, and the corresponding heating rate is 150°C / min. After the temperature rises to 550°C, adjust the microwave power to 800W, and the corresponding heating rate is 50°C / min, raise the temperature to 800°C, keep warm for 10 minutes, and then turn off the microwave Reactor, when the temperature in the system drops below 150°C, turn off the argon, and sieve the obtained solid product through a 12500-mesh filter. The solid product that passes through the filter is hollow carbon nanospheres, and the solid product that does not pas...

Embodiment 3

[0037] Taking kraft lignin, dealkalized lignin, and enzymatic lignin mixed lignin (the mixing mass ratio of the three is 1:3:2) as an example to introduce the implementation process of the present invention as follows:

[0038] Put 10 grams of mixed lignin with a particle size of less than 50 μm in a microwave reactor, and then pass 800 mL / min of nitrogen gas for 15 minutes to eliminate the air in the microwave reaction system, then turn on the microwave reactor for microwave-assisted heating, and the microwave frequency is 2.45 GHz , the microwave power is 1400W, and the corresponding heating rate is 100°C / min. After the temperature rises to 450°C, adjust the microwave power to 550W, and the corresponding heating rate is 30°C / min, raise the temperature to 700°C, keep warm for 20 minutes, and then turn off the microwave Reactor, when the temperature in the system drops below 150°C, turn off the nitrogen, and sieve the obtained solid product through a 12500 mesh filter. The soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com