Hard carbon material and preparing method and application thereof

A hard carbon and pyrolysis reaction technology, applied in the field of materials, can solve the problems of complex preparation methods of flake hard carbon, and achieve the effects of source of raw materials, economy, good electrochemical performance and wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of hard carbon material, comprises the following steps:

[0031] The citric acid is placed in a protective atmosphere, and the pyrolysis reaction is carried out to obtain a hard carbon material.

[0032] After heating, citric acid will undergo polymolecular linear polycondensation to form higher molecular weight linear compounds, or undergo intramolecular dehydration to form rings, and polymerize between ring molecules to form higher molecular weight polymers. During the pyrolysis reaction, citric acid is melted, dehydrated, polymerized, and finally pyrolyzed into a hard carbon material with a two-dimensional structure.

[0033] The present invention directly adopts citric acid to carry out a one-step pyrolysis reaction under a protective atmosphere, and prepares a hard carbon material with a unique sheet structure and a large number of micropores and mesopores, and uses the hard carbon material as a negative electrode active material to pre...

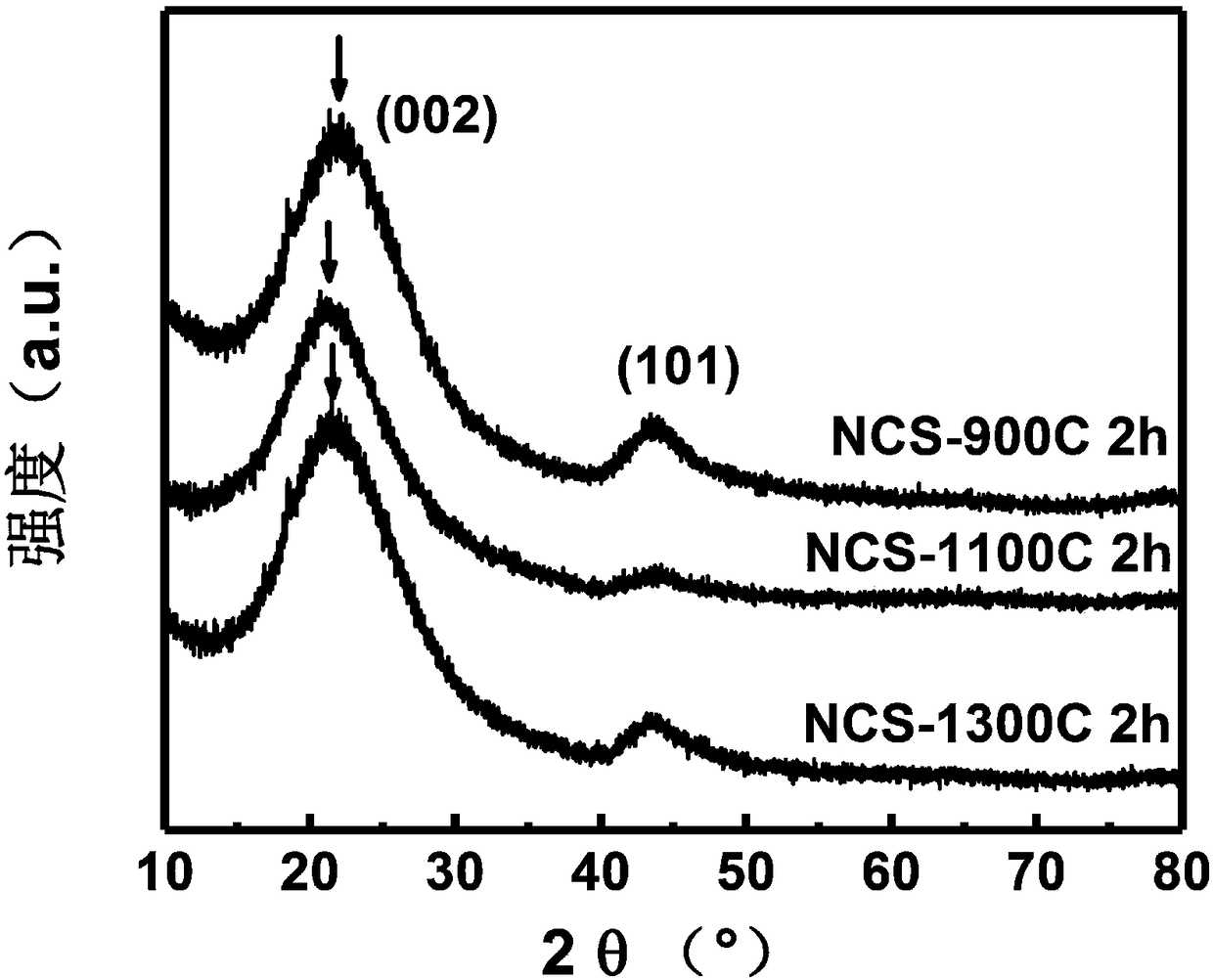

Embodiment 1

[0054] Put 50g of citric acid monohydrate in a tube furnace, and carry out pyrolysis reaction under argon atmosphere. The pyrolysis reaction includes heating up to 900°C at a heating rate of 5°C / min, keeping at 900°C for 2h, and cooling to room temperature naturally. A hard carbon material 1 (number: NCS-900C 2h) was obtained.

Embodiment 2

[0056] Put 50g of citric acid monohydrate in a tube furnace, and carry out pyrolysis reaction under an argon atmosphere. The pyrolysis reaction includes heating up to 1100°C at a heating rate of 5°C / min, keeping at 1100°C for 2h, and naturally cooling to room temperature. A hard carbon material 2 (number: NCS-1100C 2h) was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com