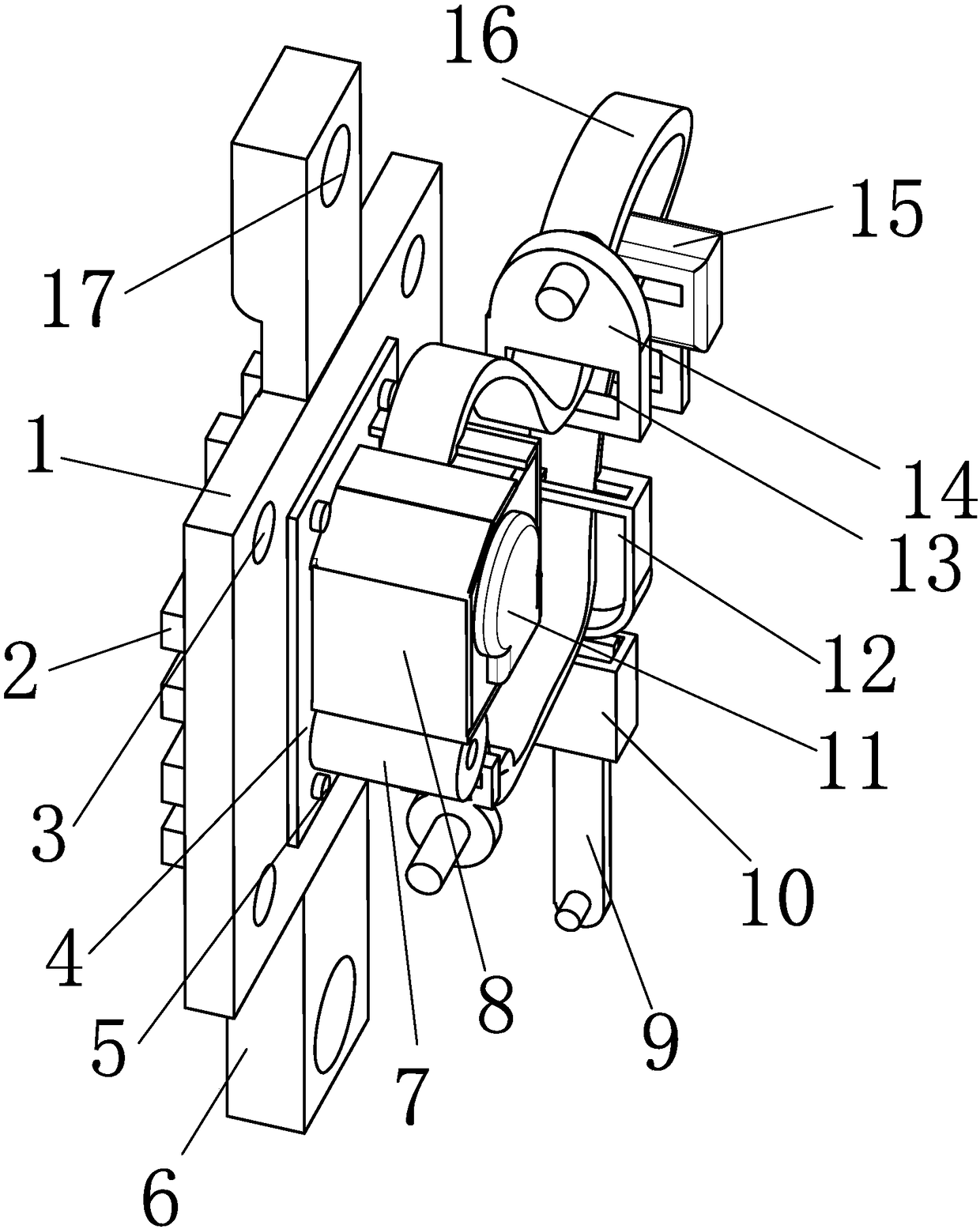

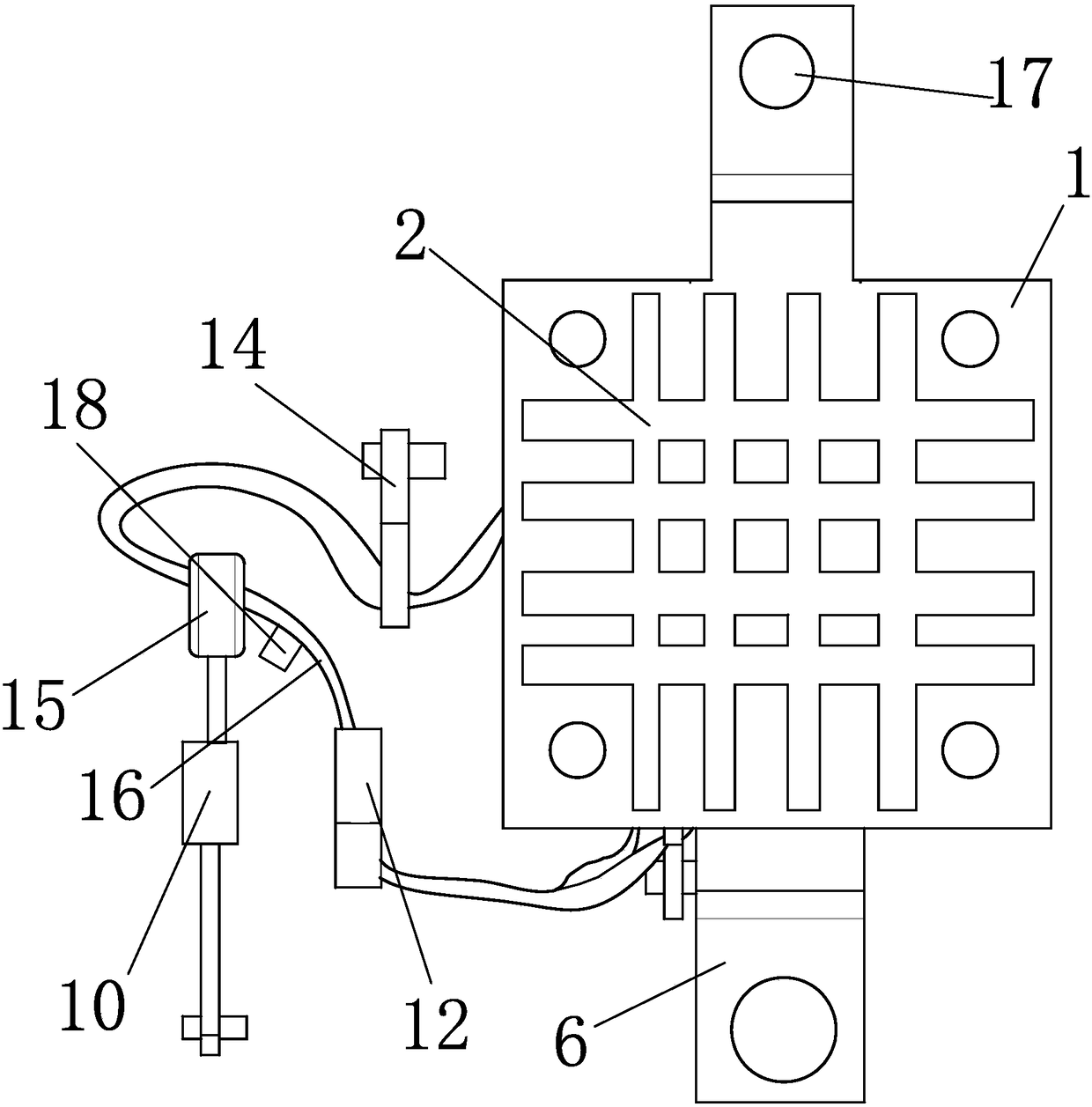

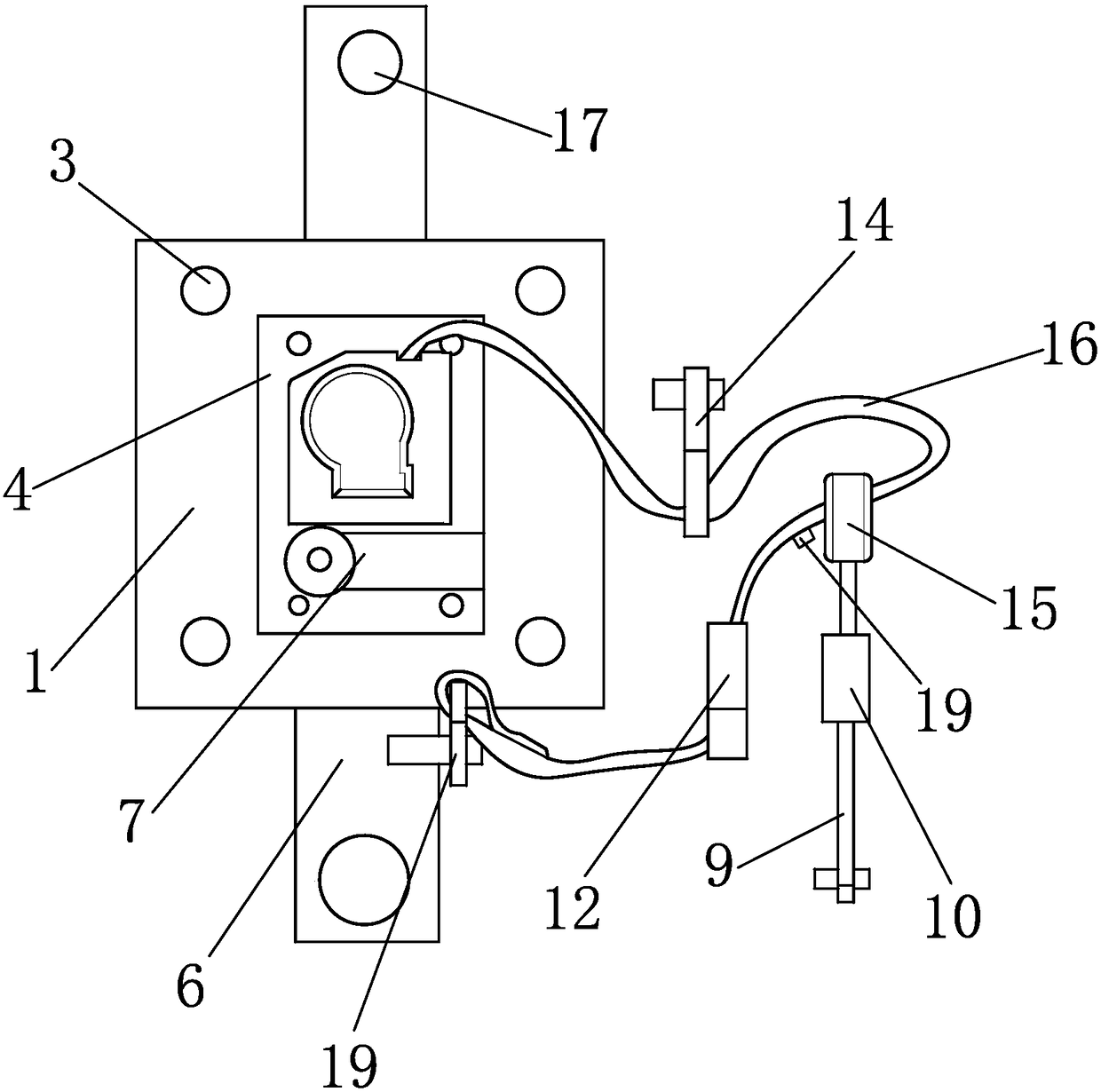

Installation structure of automobile back-row safety belt

A technology for installation structure and seat belts, which is applied in belt fixing devices, coatings, anti-corrosion coatings, etc., and can solve the problems of low installation strength and efficiency of rear seat belts, cracked inner panels of rear side walls, and large number of reinforcement plates, etc. , to achieve the effect of firm parts, increased use safety, and uniform design of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The anticorrosion coating of the present invention consists of the following components by weight: 38 parts of bisphenol F liquid epoxy resin, 20 parts of petroleum resin, 30 parts of polysulfide modified epoxy resin, 45 parts of xylene, and 12 parts of butyl acetate , 15 parts of nano-silica powder, 1 part of iron oxide red, 15 parts of chromium chloride, 12 parts of diisobutyl phthalate, and 0.1 part of carbon black.

Embodiment 2

[0023] The anticorrosion coating of the present invention consists of the following components by weight: 20 parts of bisphenol F liquid epoxy resin, 10 parts of petroleum resin, 16 parts of polysulfide modified epoxy resin, 25 parts of xylene, and 6 parts of butyl acetate , 5 parts of nano-silica powder, 5 parts of iron oxide red, 10 parts of chromium chloride, 5 parts of diisobutyl phthalate, and 2 parts of carbon black.

Embodiment 3

[0025] The anticorrosion coating of the present invention consists of the following components by weight: 26 parts of bisphenol F liquid epoxy resin, 15 parts of petroleum resin, 20 parts of polysulfide modified epoxy resin, 30 parts of xylene, and 8 parts of butyl acetate , 10 parts of nano-silica powder, 2 parts of iron oxide red, 12 parts of chromium chloride, 9 parts of diisobutyl phthalate, and 0.5 part of carbon black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com