Short-flow efficient production process of double-metal composite belt material

A production process and composite strip technology, applied in metal rolling and other directions, can solve the problems of easy oxidation of high melting point metal strip surface, low interface bonding strength, and environmental burden, and achieve easy control of product uniformity and interface bonding quality High, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

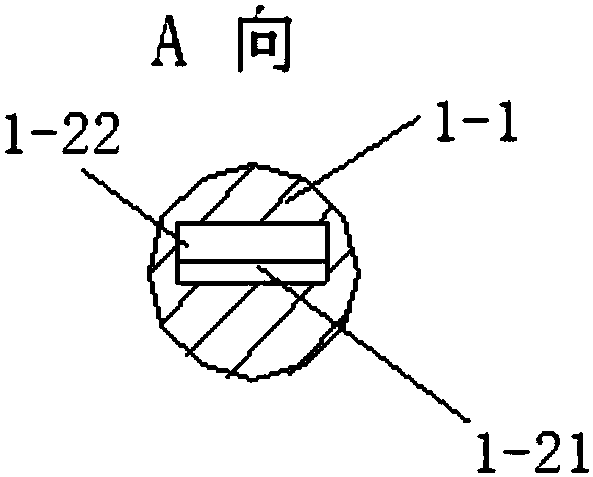

Image

Examples

Embodiment 1

[0045] The short-process production process of copper-aluminum composite strip with a width of 100mm and a thickness of 0.3mm, the thickness of the copper layer of the strip accounts for 25% of the total thickness.

[0046] (1) Using T2 pure copper and 1070 pure aluminum as raw materials, a continuous casting composite process is used to prepare a copper-aluminum composite slab with a width of 100mm and a thickness of 25mm and a metallurgical bonding interface in one step. Among them, the casting temperature of molten copper and molten aluminum 1150°C and 750°C respectively, the primary cooling water flow rate is set to 800L / h, the secondary cooling water flow rate is 200L / h, and the continuous casting speed is 100mm / min;

[0047] (2) Put the copper-aluminum composite slab prepared by continuous casting in a heating furnace for heating, the heating temperature is 250°C, and the heating time is 30 minutes;

[0048] (3) The heated slab is warm-rolled by a single-stand reciprocat...

Embodiment 2

[0052] The short-process production process of 3003 / 4004 double aluminum composite strip with a width of 200mm and a thickness of 0.4mm, the thickness of 3003 of the strip accounts for 20% of the total thickness.

[0053] (1) Using 3003 and 4004 as raw materials, a continuous casting composite process was used to prepare a double-aluminum composite slab with a width of 200mm and a thickness of 20mm and a metallurgical bonding interface in one step. The cooling water flow rate is set to 1000L / h, the secondary cooling water flow rate is 500L / h, and the continuous casting speed is 120mm / min;

[0054] (2) Put the double-aluminum composite slab prepared by continuous casting in a heating furnace for heating, the heating temperature is 200°C, and the heating time is 30 minutes;

[0055] (3) The heated slab is warm-rolled and formed by a single-stand reciprocating flat-roll rolling mill. The reduction rate of the first pass is controlled at 50%, and the reduction rate of the subseque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com