Water-resistant granite paint and construction technology thereof

A technology of granite coating and construction technology, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., which can solve problems such as uneven construction, affecting appearance, easy yellowing, etc., to ensure the decorative effect and quality Requirements, good construction effect, effect with distinct layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

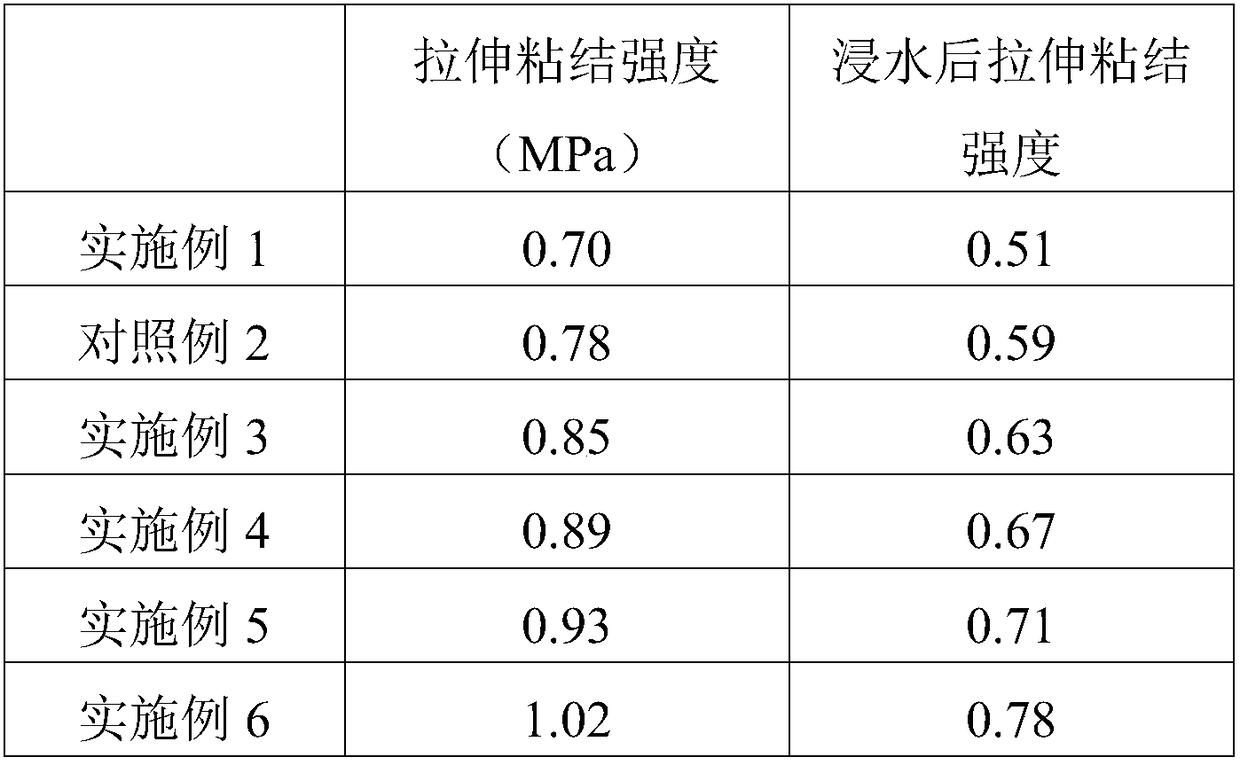

Examples

Embodiment 1

[0065] The construction technology of water-resistant granite coating includes the following steps:

[0066] S1 base treatment: remove the sundries on the coating base surface, and use cement to fill up the local unevenness or surface cracks to ensure the base surface is smooth;

[0067] S2 Spraying primer: Apply primer evenly on the coating base surface to form a primer film with a thickness of 0.1mm for back sealing treatment; when painting primer, spray the small surface first and then the large surface, from top to bottom Brush evenly;

[0068] S3 Spray topcoat: 24 hours after the primer is sprayed, spray the topcoat for the first time on the base surface coated with primer to form a topcoat film with a thickness of 0.1mm; spray the topcoat for the first time After 24 hours, spray the topcoat for the second time to form a topcoat film with a thickness of 0.1mm again;

[0069] S4 Elastic line, grid, adhesive tape: segment the coating base surface to form a well-shaped gri...

Embodiment 2

[0075] It is basically the same as Example 1, the only difference is:

[0076] The preparation process of the water-resistant granite coating is as follows: add 100 g of deionized water to the container, and then add 3 g of dispersant, 1 g of wetting agent, 0.5 g of defoamer and hydroxyethyl methylcellulose in succession under stirring at 300 rpm. 1g of plain ether; after adding, increase the speed to 1000 rpm, stir for 5 minutes, then add 40g of film-forming aid, and stir for 3 minutes; then reduce the speed to 500 rpm, add 300g of styrene-acrylic emulsion, and stir for 20 minutes , using sodium hydroxide to adjust the pH to 8, and continue to stir for 5 minutes to obtain a slurry; under stirring at 500 rpm, add 800 g of 40-mesh natural colored sand to the slurry while stirring, and increase the speed to 800 after adding rev / min, stirring for 5 minutes; under stirring at 800 rev / min, add 1g of anti-corrosion and anti-fungal agent, 0.5g of defoamer and 0.1g of thickener succes...

Embodiment 3

[0079] It is basically the same as Example 2, except that the styrene-acrylic emulsion uses a core-shell type styrene-acrylic emulsion.

[0080] The core-shell type styrene-acrylic emulsion is obtained by the following method:

[0081] (1) Preparation of nuclear layer pre-emulsion: dissolve 10 g of sodium methacrylate hydroxypropyl sulfonate with 200 g of water, stir at 600 rpm for 10 minutes, then add 50 g of styrene, 200 g of isooctyl acrylate, and 4 g of acrylamide , methacrylic acid 4g, potassium persulfate 2g, stirred for 30 minutes with 600 revs / min, obtained nuclear layer pre-emulsion;

[0082] (2) Preparation of shell pre-emulsion: dissolve 10 g of sodium methacrylate hydroxypropyl sulfonate with 200 g of water, stir at 600 rpm for 10 minutes, then add 100 g of styrene, 50 g of methyl methacrylate, and isoacrylate Octyl ester 100g, acrylamide 4g, methacrylic acid 4g, N-methylolacrylamide 4g, potassium persulfate 2g, stirred at 600 rpm for 30 minutes to obtain a shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com