Multilayer metal mask seed layer for glass HF etching and manufacturing method thereof

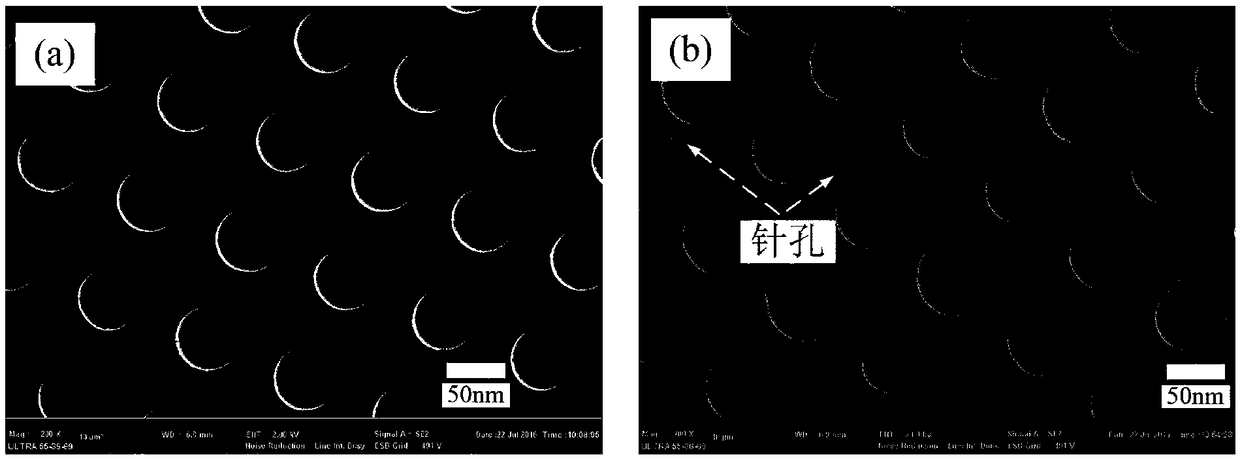

A multi-layer metal and metal mask technology, applied in the field of mask layers, can solve problems such as poor effect, uneven corrosion, pinholes, etc., and achieve the effect of avoiding undercutting, good uniformity and outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

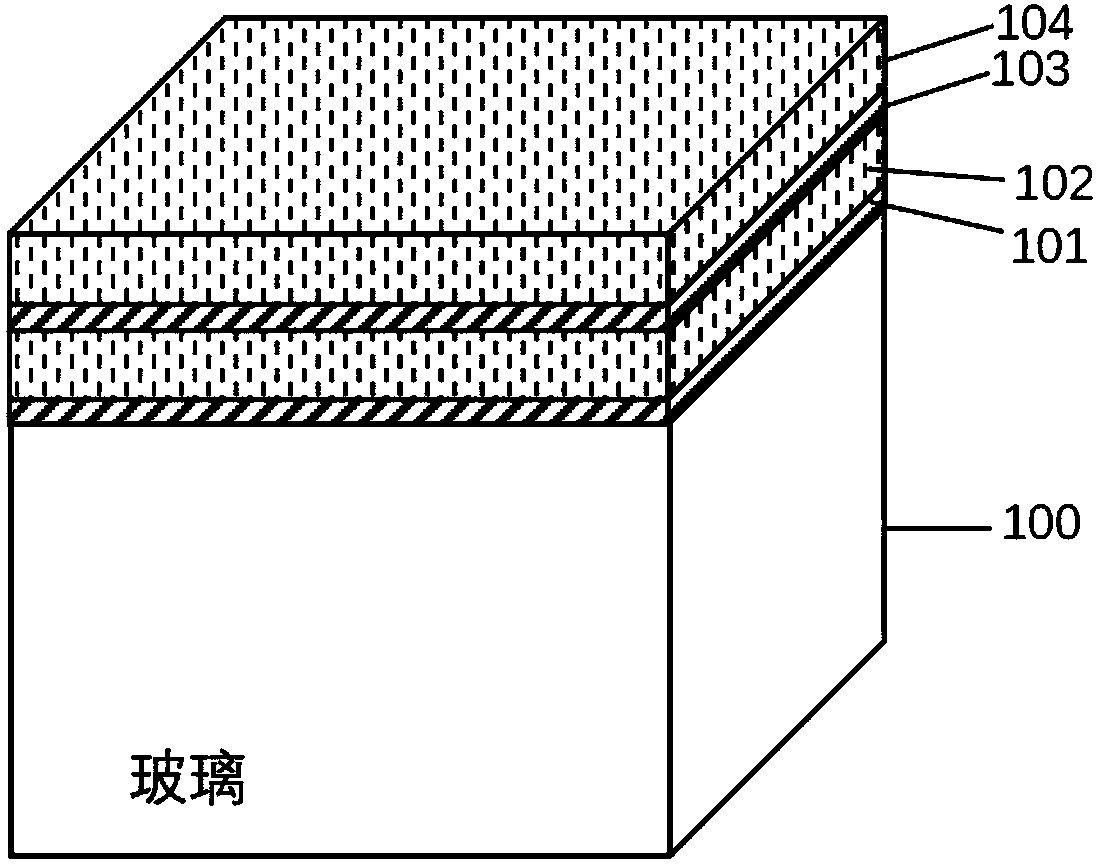

[0025] Such as figure 1 Shown: a kind of multi-layer metal mask seed layer that is used for glass HF corrosion of the present embodiment, described metal mask is four layers, from glass substrate 100 upwards successively is the first Cr layer 101, the first Cu layer 102, a second Cr layer 103, and a second Cu layer 104, forming a complex mask layer structure of Cr / Cu / Cr / Cu. Both the first Cr layer 101 and the second Cr layer 103 have a thickness of 50 nm, and the first Cu layer 102 and the second Cu layer 104 have a thickness of 200 nm.

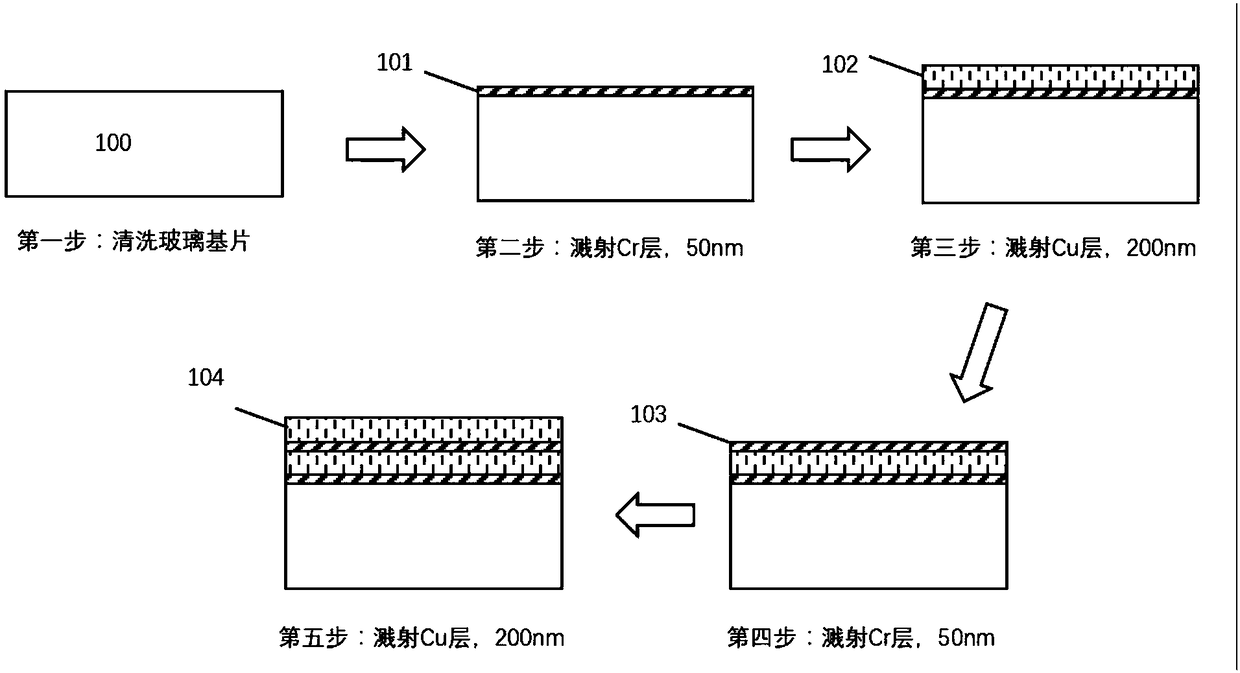

[0026] Such as figure 2 As shown, the preparation method of the multilayer metal mask seed layer of the present embodiment is to go through the following steps in sequence:

[0027] Step 1: Sputter a first Cr layer 101 with a thickness of 50 nm on the surface of a clean and dry glass substrate 100 by magnetron sputtering;

[0028] The second step: sputtering a first Cu layer 102 with a thickness of 200 nm on the basis of the first step; ...

Embodiment 2

[0041] When the thicknesses of each layer of the prepared Cr / Cu / Cr / Cu multilayer mask layer are 10nm / 100nm / 10nm / 100nm, the others are the same as in Example 1.

Embodiment 3

[0043] When the thicknesses of each layer of the obtained Cr / Cu / Cr / Cu multilayer mask layer are 100nm / 300nm / 100nm / 300nm respectively, the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com