A water-lifting aeration water quality improving device enhanced through bubble cutting and bio-contact oxidation

A technology of biological contact, water pumping and aeration, applied in the field of water treatment, can solve the problems of endangering the safety of drinking water and human health, frequent occurrence of eutrophication in water bodies, and pollution of water sources, so as to inhibit the growth of algae, reduce energy consumption, reduce The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

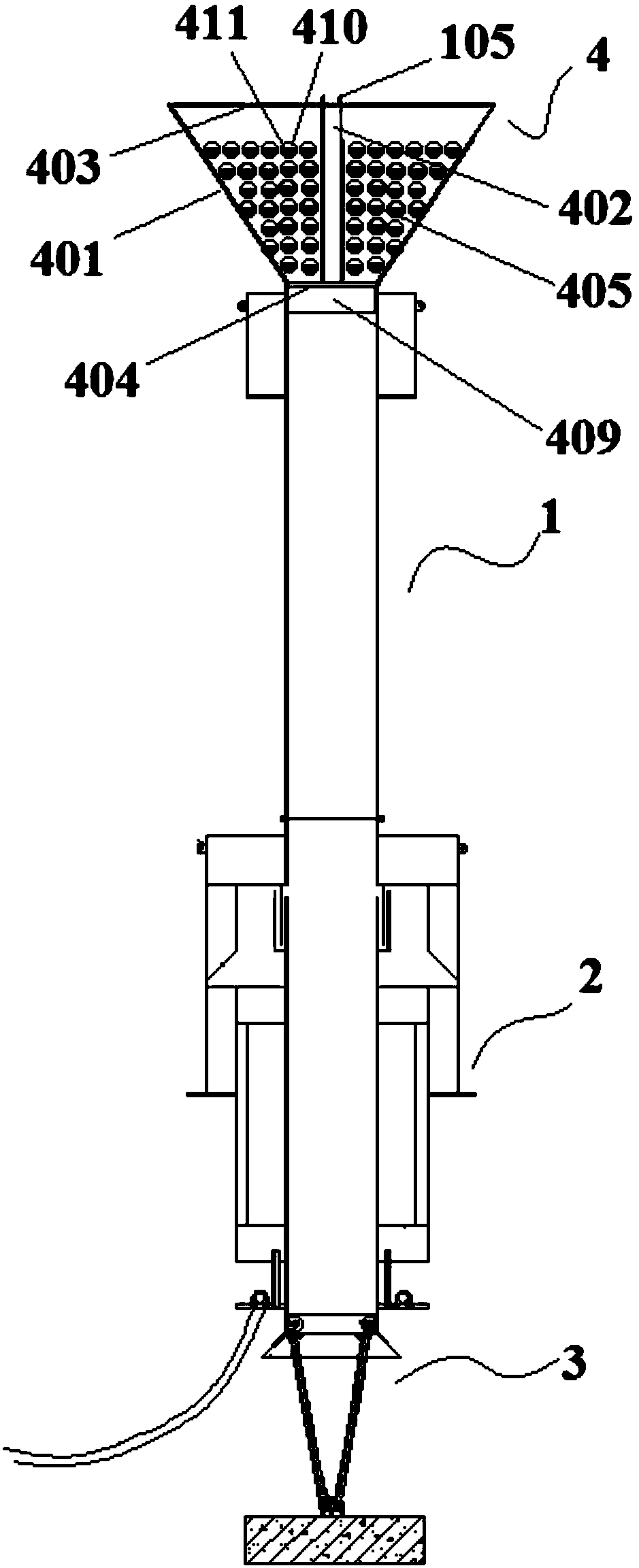

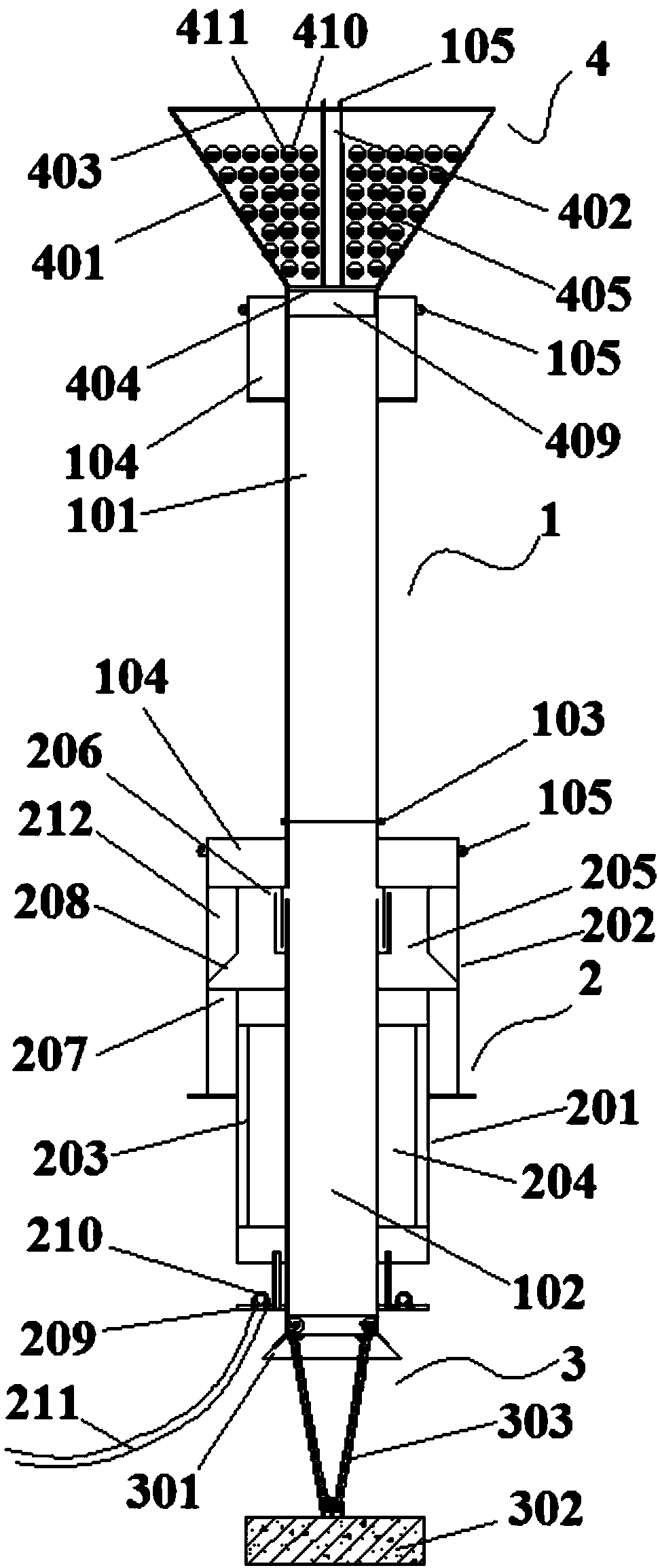

[0044] Comply with the above technical solutions, such as Figure 1 to Figure 2 As shown, the present embodiment provides a biological contact oxidation device, which includes an inverted cone-shaped cabin 401 with open ends. The inner diameter of the bottom of the cabin 401 is smaller than the inner diameter of the top. The tops are fastened together;

[0045] The cabin body 401 is provided with a hoisting central tube 402, the top of the hoisting central tube 402 and the top of the cabin body 401 are installed together through the air bubble cutting grille cover plate 403, the bottom end of the hoisting central tube 402 is connected to the top of the cabin body 401 The bottom end is installed together by the air bubble cutting water distribution grid 404, the cabin body 401, the hoisting central cylinder 402 and the lifting cylinder unit 1 are coaxially arranged, and the cavity between the cabin body 401 and the hoisting central cylinder 402 is the filler filling chamber 405...

Embodiment 2

[0054] Comply with the above technical solutions, such as Figure 1 to Figure 2 As shown, this embodiment provides a device for improving water quality by air bubble cutting biological contact oxidation enhanced pumping and aeration, which includes a rising cylinder unit 1, a main aeration unit 2 is arranged at the bottom of the rising cylinder unit 1, and a bottom end of the rising cylinder unit 1 is provided with An anchoring unit 3, a biological contact oxidation unit 4 is arranged on the top of the ascending cylinder unit 1;

[0055] The biological contact oxidation unit 4 adopts the biological contact oxidation device described in Example 1.

[0056] During the operation of the equipment, the rising water flow enters the filler filling chamber 405 through the air bubble cutting water distribution grid 404, and the water body is in contact with the filler, thereby performing bioremediation of the water body through biological contact oxidation, effectively reducing the con...

Embodiment 3

[0059] Comply with the above technical solutions, such as Figure 2 to Figure 3 As shown, this embodiment provides a device for improving water quality by air bubble cutting biological contact oxidation enhanced water pumping and aeration. And the anchoring unit 3 can take the following specific scheme as an example to illustrate the scheme of the present application.

[0060] Specifically, the ascending cylinder unit 1 includes an upper ascending cylinder 101 and a lower ascending cylinder 102 connected together by a flange 103, the top of the upper ascending cylinder 101 is affixed to the bottom of the cabin body 101; The end is affixed to the trumpet-shaped inlet 301 of the anchor unit 3 .

[0061] Both the upper ascending cylinder 101 and the lower ascending cylinder 102 are provided with an airtight chamber 104; the airtight chamber 104 is used to provide buoyancy, and the fixed cylinder is relatively stable and suspended in water.

[0062] Lifting lugs 105 are provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com