Novel ready-to-use aerogel microsphere and preparation method thereof

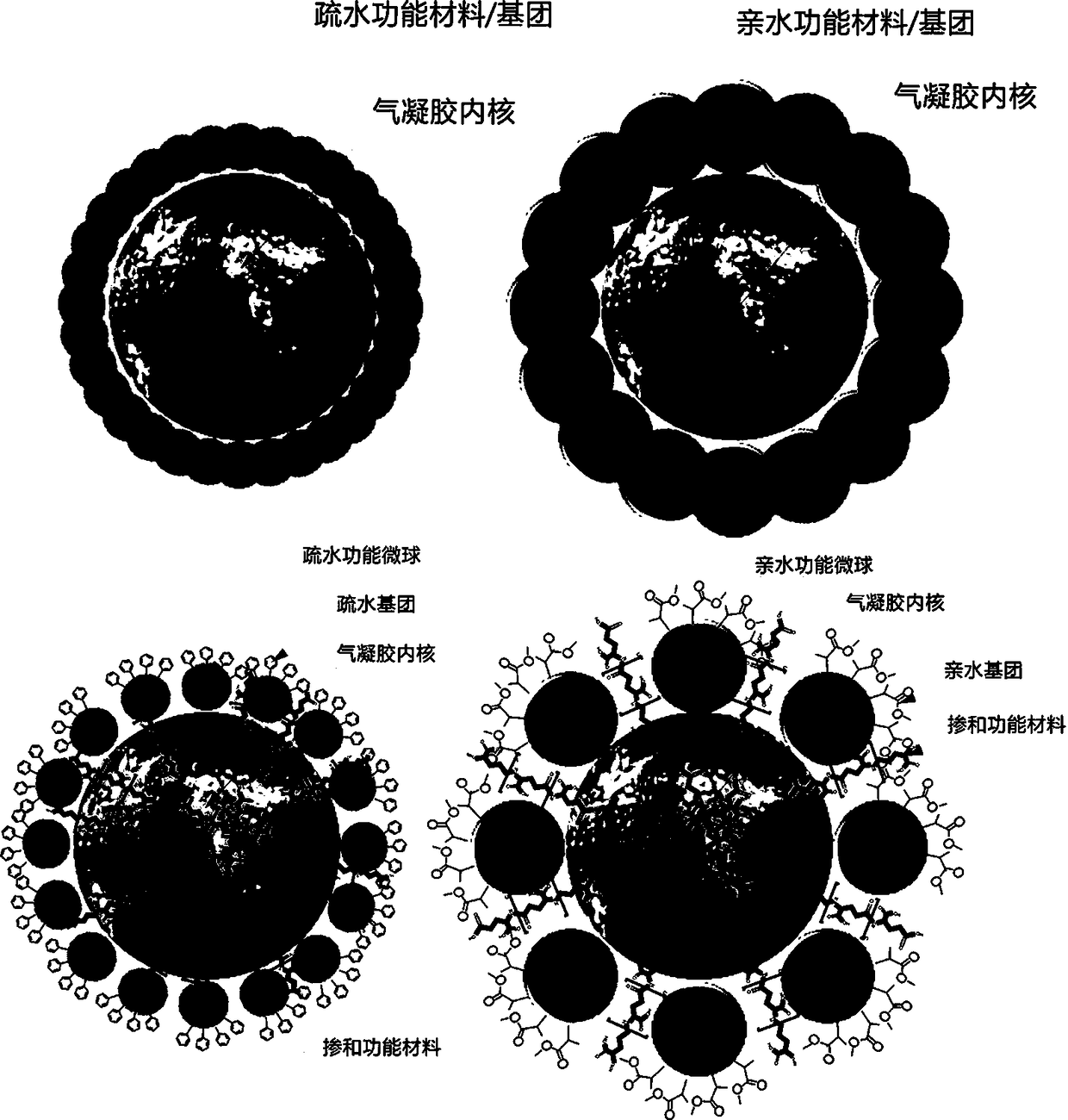

An airgel and microsphere technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of denaturation of active substances, easy aggregation and precipitation, latex demulsification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

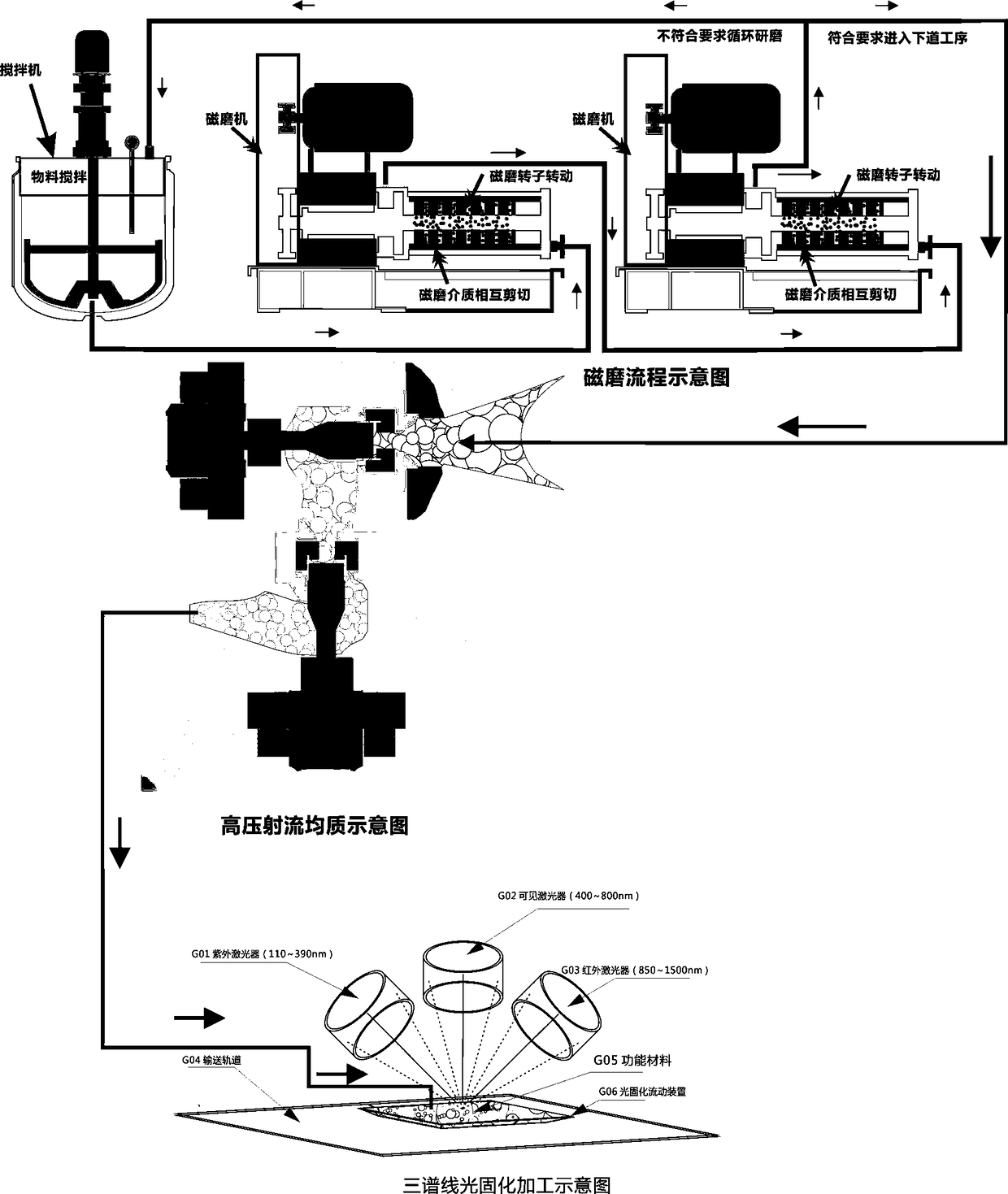

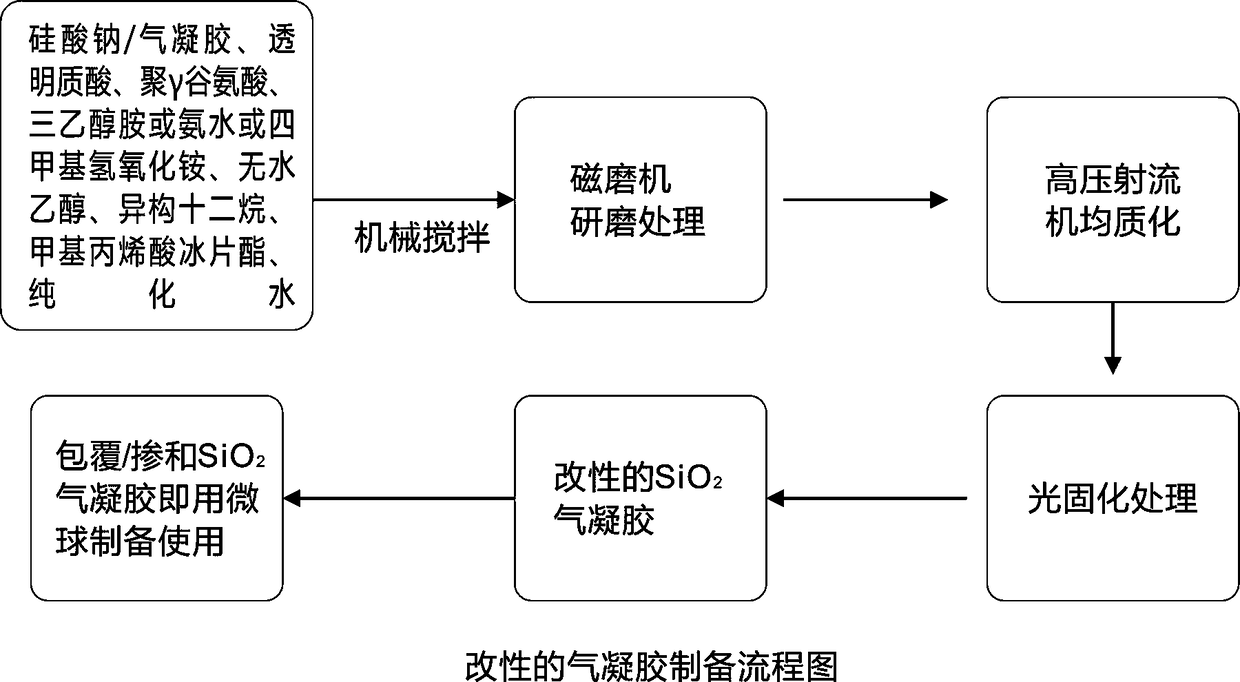

Method used

Image

Examples

Embodiment 1

[0143] The ready-to-use airgel microsphere emulsion was prepared by mixing 170 nanometer size silica airgel particles (600g), poly(methyl vinyl ether / maleic acid) half ester copolymer (5.0g), absolute ethanol ( 150 ml), added to 6.7 liters of isododecane, fully ground in a magnetic grinder for later use; Hyaluronic acid elastomer (1.0g), lauryl trimethylamine oxide (1.5g), absolute ethanol (150ml), ammonia water (9.0ml), purified water (2.9L) after stirring and dissolving in a high-speed homogenizer Slowly add dropwise to the above-mentioned standby silica airgel suspension, and then quickly add it to the high-pressure jet homogenizer, use the rated (flow rate: 6L / h, working pressure: 800bar, machine stroke number: 110 times / min , maximum product temperature: 80°C) after homogenization treatment, and then three-spectrum high-energy light curing treatment, cycle twice to get the pretreated ready-to-use airgel microsphere suspension. The ready-to-use airgel microspheres can be ...

Embodiment 2

[0145] The ready-to-use airgel microsphere emulsion was prepared by mixing 110 nanometer size silica airgel particles (300g), poly(methyl vinyl ether / maleic acid) half ester copolymer (3.0g), absolute ethanol ( 300 ml), added to 7.7 liters of isododecane, bis((3,4-epoxycyclohexyl)methyl)adipate and isobornyl methacrylate in a 33:1:1 mixture, in Grind fully in a magnetic mill in the dark for later use; in addition, weigh poly-γ-glutamic acid (2.0 g), low-acyl gellan gum (0.10 g), acetylated sodium hyaluronate (0.5 g), polyethylene Pyrrolidone K90 ((4.5g)), 2,4,7,9-tetramethyl-5-decyne-4,7-diol (1.0g), ammonia (4.5ml), purified water (2.0L) high speed After the homogenizer stirs and dissolves, slowly add it dropwise to the above-mentioned standby silica airgel suspension, and then quickly add it to the high-pressure jet homogenizer, use the rated (flow rate: 6L / h, working pressure: 800bar, machine stroke number: 110 times / min, maximum product temperature: 80°C) after homogeniza...

Embodiment 3

[0147]The ready-to-use airgel microsphere emulsion was obtained by mixing 250 nanometer size silica airgel particles (450g), poly(methyl vinyl ether / maleic acid) half ester copolymer (3.0g), absolute ethanol ( 300 ml), to 6.7 liters of 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, fluorinated diphenyl titanocene and isobornyl methacrylate 1:1: 60 mixed solution, fully ground in a magnetic mill under the condition of avoiding light for later use; in addition, weigh poly-γ-glutamic acid (1.0g), high-acyl gellan gum (0.02g), sodium hyaluronate oligosaccharide (0.5 g), polyvinylpyrrolidone K60 ((3.0g)), 2,4,7,9-tetramethyl-5-decyne-4,7-diol (1.5g), ammonia water (5.5ml), purified water (2.9 liters) after stirring and dissolving with a high-speed homogenizer, slowly add it dropwise to the above-mentioned spare silica airgel suspension, and then quickly add it to the high-pressure jet homogenizer, use the rated (flow rate: 6L / h, working pressure : 800bar, number of machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com