A cmos driver for output signal slew rate control

An output signal, slew rate technology, applied in the direction of automatic power control, electrical components, etc., can solve the problems of large changes in driving capability, changes in output signal slew rate, etc., to achieve the effect of improving process deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

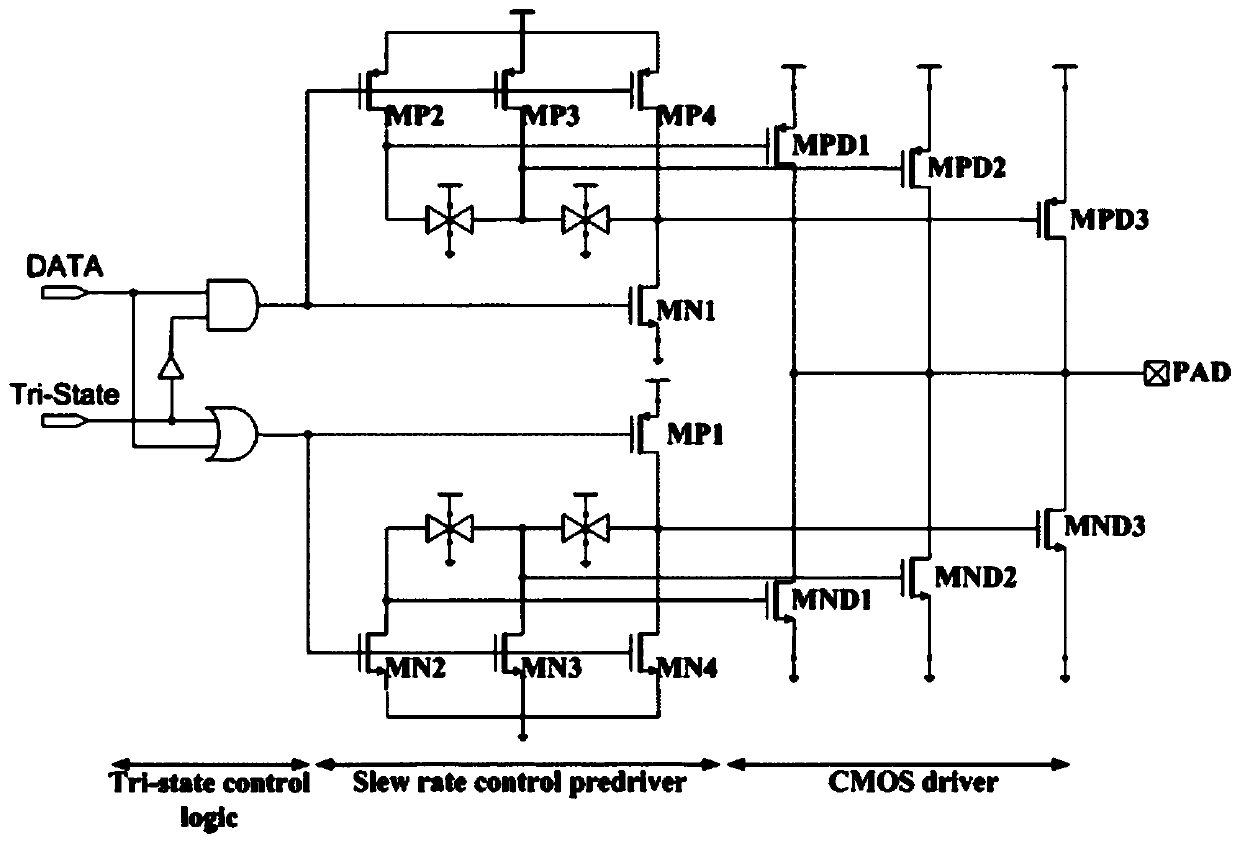

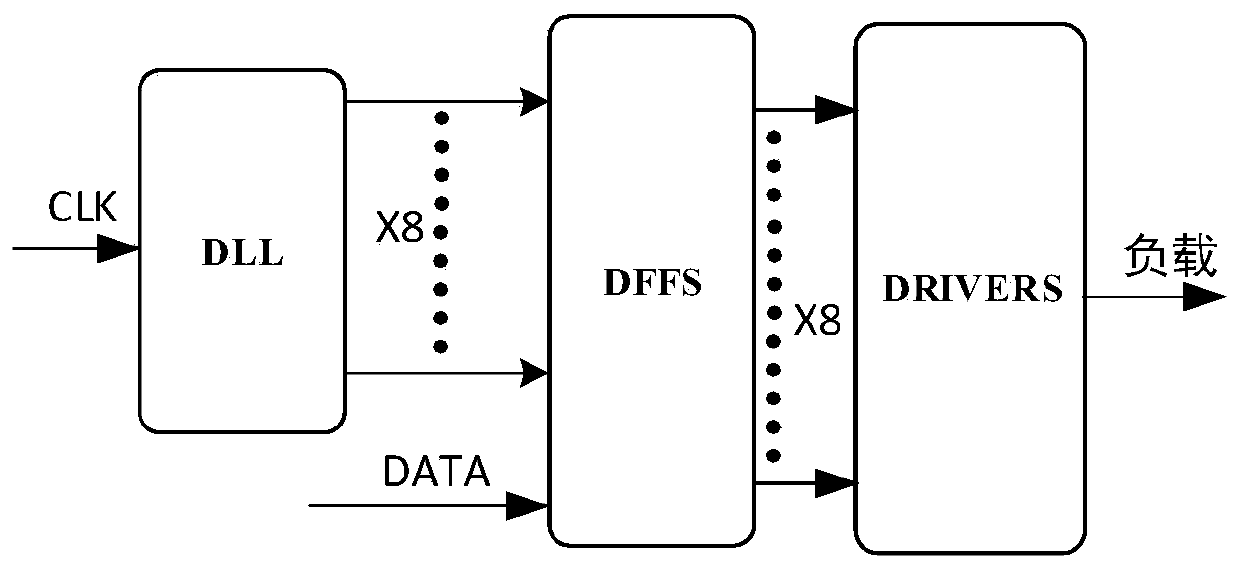

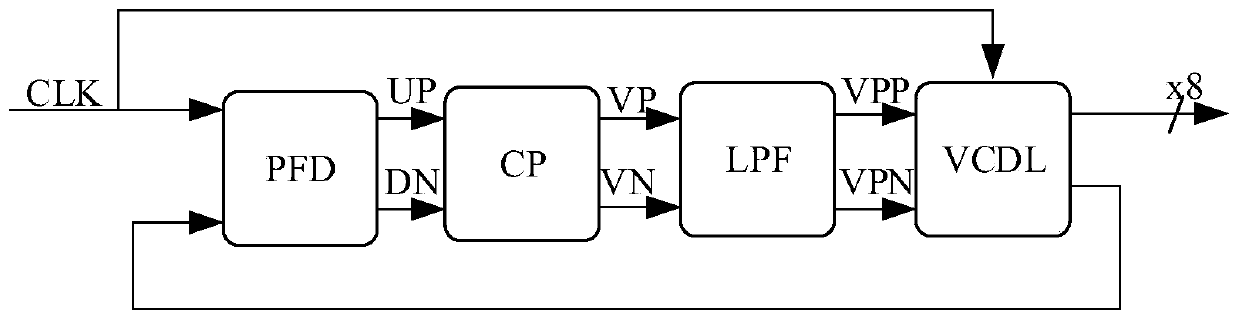

[0022] Aiming at the problem that the traditional three-state gate output signal slew rate control driver changes with the PVT, the driving capability changes greatly, resulting in a large change in the output signal slew rate. The present invention designs a CMOS driver applied to output signal slew rate control, and its driving ability does not change with process deviation, working environment temperature and power supply voltage. The present invention uses a delay phase-locked loop to generate an equal-delay signal that does not change with PVT , and then use 8 equal-delay signals for superimposition and averaging to achieve a constant rising and falling speed of the output signal jump edge, that is, to generate an output slew rate signal that does not vary with proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com