Synthesis of iron-supported nitrogen-doped porous carbon materials with excellent electrocatalytic oxygen reduction performance

A technology of nitrogen-doped porous carbon and synthesis method, which is applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, can solve the problems of high price, inactivation, and easy poisoning, and achieve low price and environmental Small pollution, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of synthetic method of the nitrogen-doped porous carbon material of iron load with excellent electrocatalytic oxygen reduction performance, comprises the steps:

[0030] 1) Mix 150 parts of pentacyanoammonium ferric acid sodium salt, 600 parts of molecular sieve SBA-15, 2000 parts of [VMlm]DCA and 5 parts of anhydrous N,N-dimethylformamide solution (DMF) and ultrasonically homogenize ; Add it to a hydrothermal kettle, heat it at 80-100°C for 6 hours, add 20 parts of anhydrous N,N-dimethylformamide solution and transfer it to a flask; take 20 parts of 2,2'-azobis (Isobutyronitrile) dissolved in 5 parts of anhydrous N,N-dimethylformamide solution, ultrasonically uniform, poured into the flask; nitrogen gas was passed through the above flask for 30-40 minutes, sealed, and transferred to 60-80°C oil In the bath, stop the reaction after stirring for 6-10 hours;

[0031] 2) Drop the solution in step 1) into 200 parts of acetone solution. After standing still, suction ...

Embodiment 1

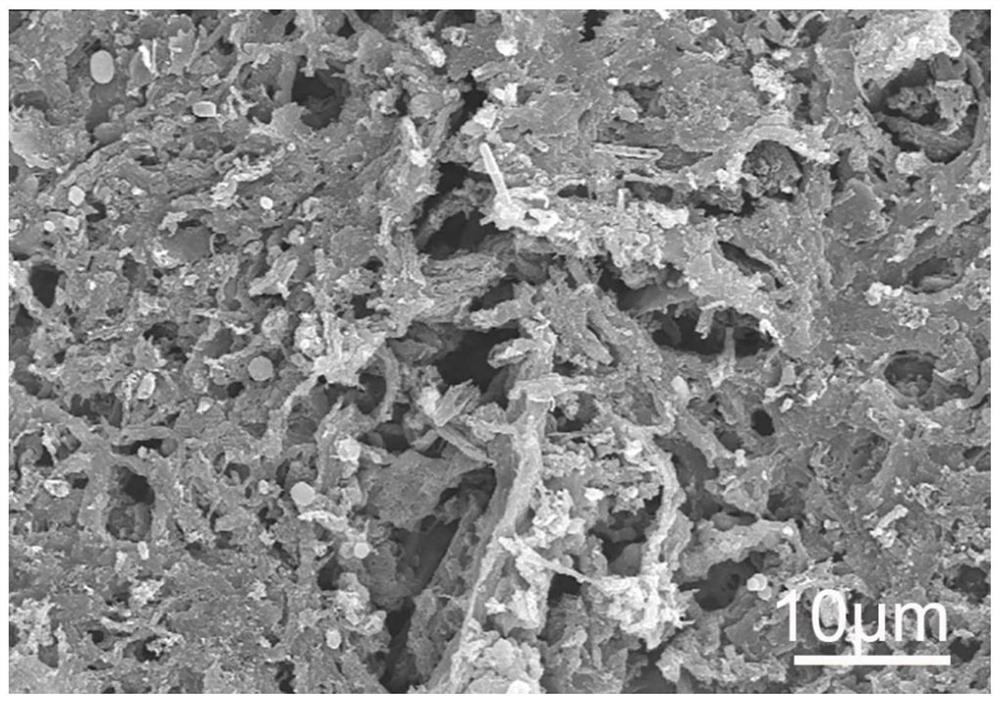

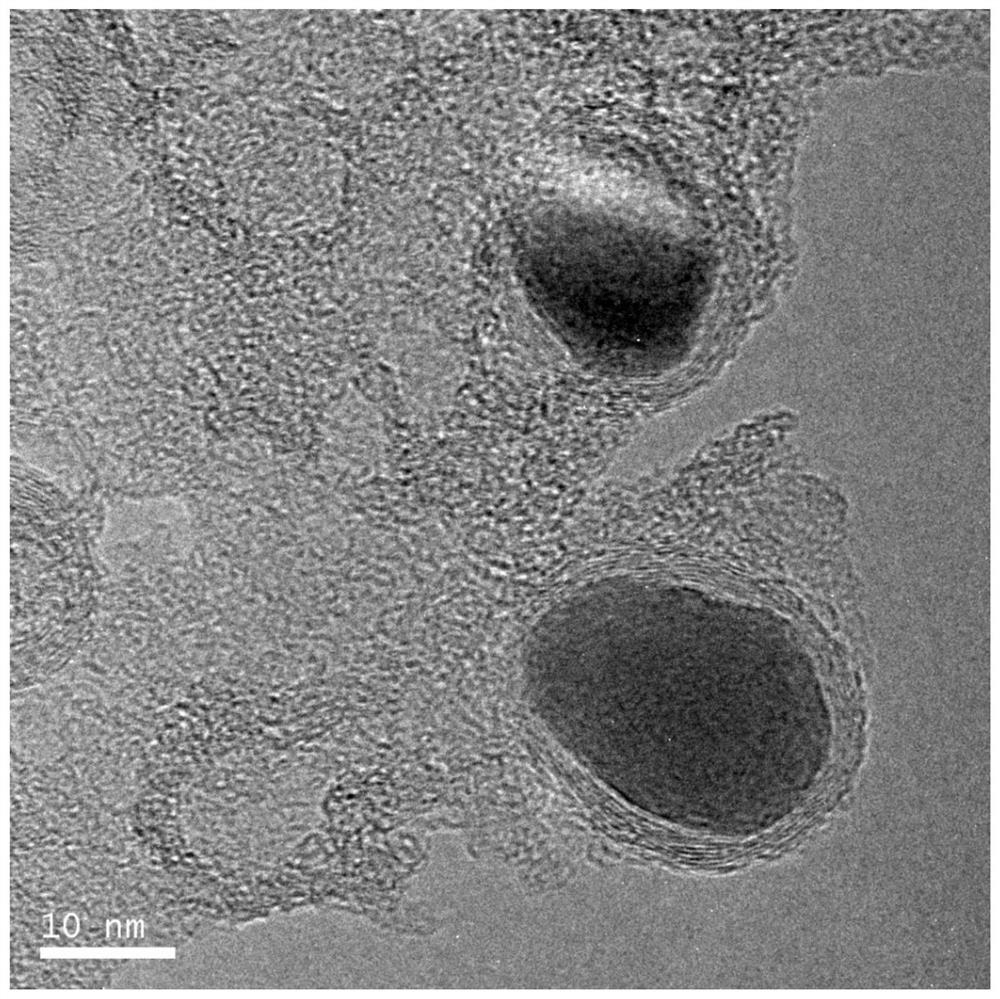

[0037] Preparation of nitrogen-doped porous carbon material Fe@NCNTs-800 supported by metallic iron:

[0038]Measure 5 mL of N,N-dimethylformamide solution (DMF) into a 50 mL beaker, add 150 mg of pentacyanoaminoferric acid sodium salt and 2000 mg of [VMlm]DCA, after ultrasonication, the mixture Transfer to the liner of a hydrothermal kettle, heat at 80°C for 6 hours, add 20 mL of N,N-dimethylformamide solution (DMF) and transfer to a 100 mL flask. Measure another 5 mL of N,N-dimethylformamide solution (DMF) into a 50 mL beaker, add 20 mg of 2,2’-azobis(isobutyronitrile), and add it into the above-mentioned flask after ultrasonication. After blowing nitrogen into the above flask for 40 minutes, seal the flask and transfer it to an oil bath at 70°C, stir and heat for 8 hours, stop the reaction, cool to room temperature, drop it into 200 mL of acetone solution, and let it stand for 2 hours Afterwards, the product was obtained by suction filtration. The product was dried in a v...

Embodiment 2

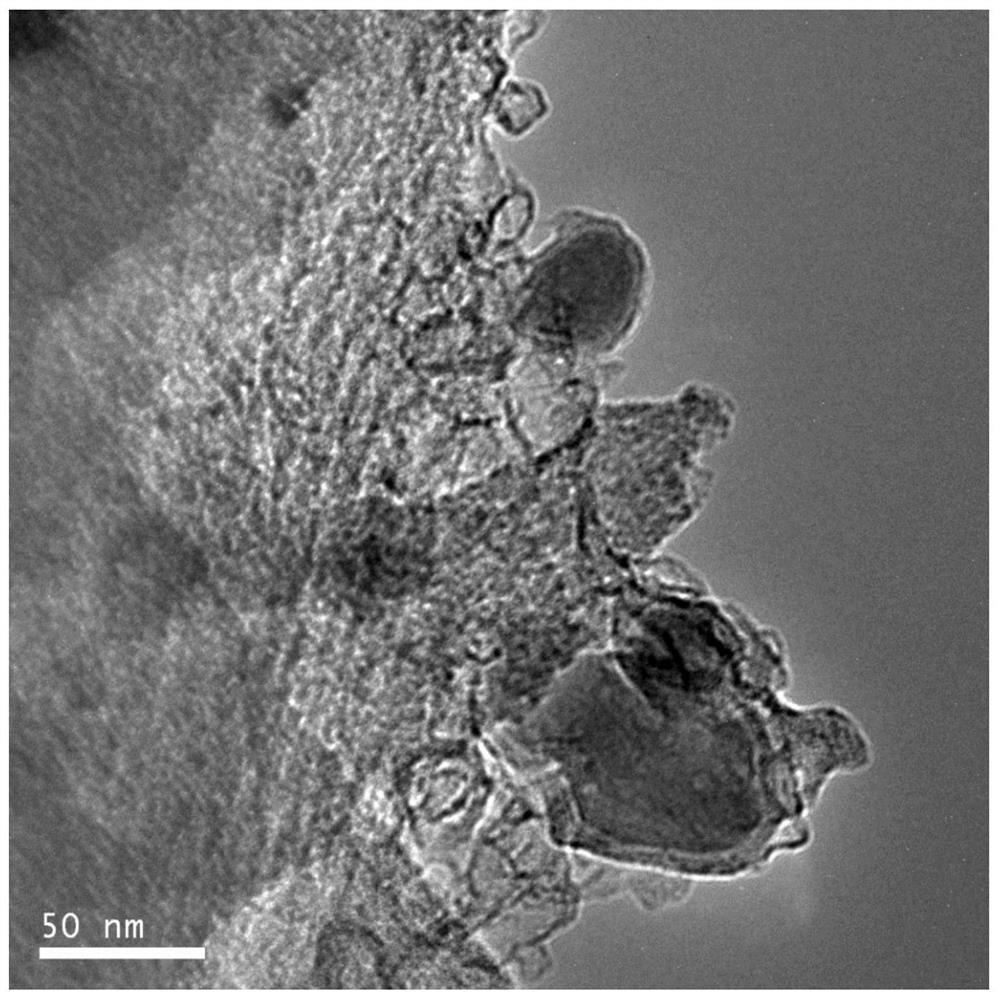

[0041] Preparation of nitrogen-doped porous carbon material Fe@NCNTs-400 supported by metallic iron:

[0042] Measure 5mL of N,N-dimethylformamide solution (DMF) into a 50 mL beaker, add 150mg of sodium pentacyanoaminoferrate and 2000 mg of [VMlm]DCA, after ultrasonication, transfer the mixture to water In the inner tank of the hot kettle, after heating with water at 80°C for 6 hours, add 20 mL of N,N-dimethylformamide solution (DMF) and transfer to a 100 mL flask. Measure another 5mL of N,N-dimethylformamide solution (DMF) into a 50 mL beaker, add 20mg of 2,2’-azobis(isobutyronitrile), and add it into the above flask after ultrasonication. After blowing nitrogen into the above flask for 40 minutes, seal the flask and transfer it to an oil bath at 70°C, stir and heat for 8 hours, stop the reaction, cool to room temperature, drop it into 200 mL of acetone solution, and let it stand, The product was obtained by suction filtration. The product was dried in a vacuum oven at 80° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com