Rice vibration dryer

A technology for drying machine and rice, applied in the direction of drying machine, drying machine, non-progressive drying machine, etc., can solve the problem of uneven heating of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

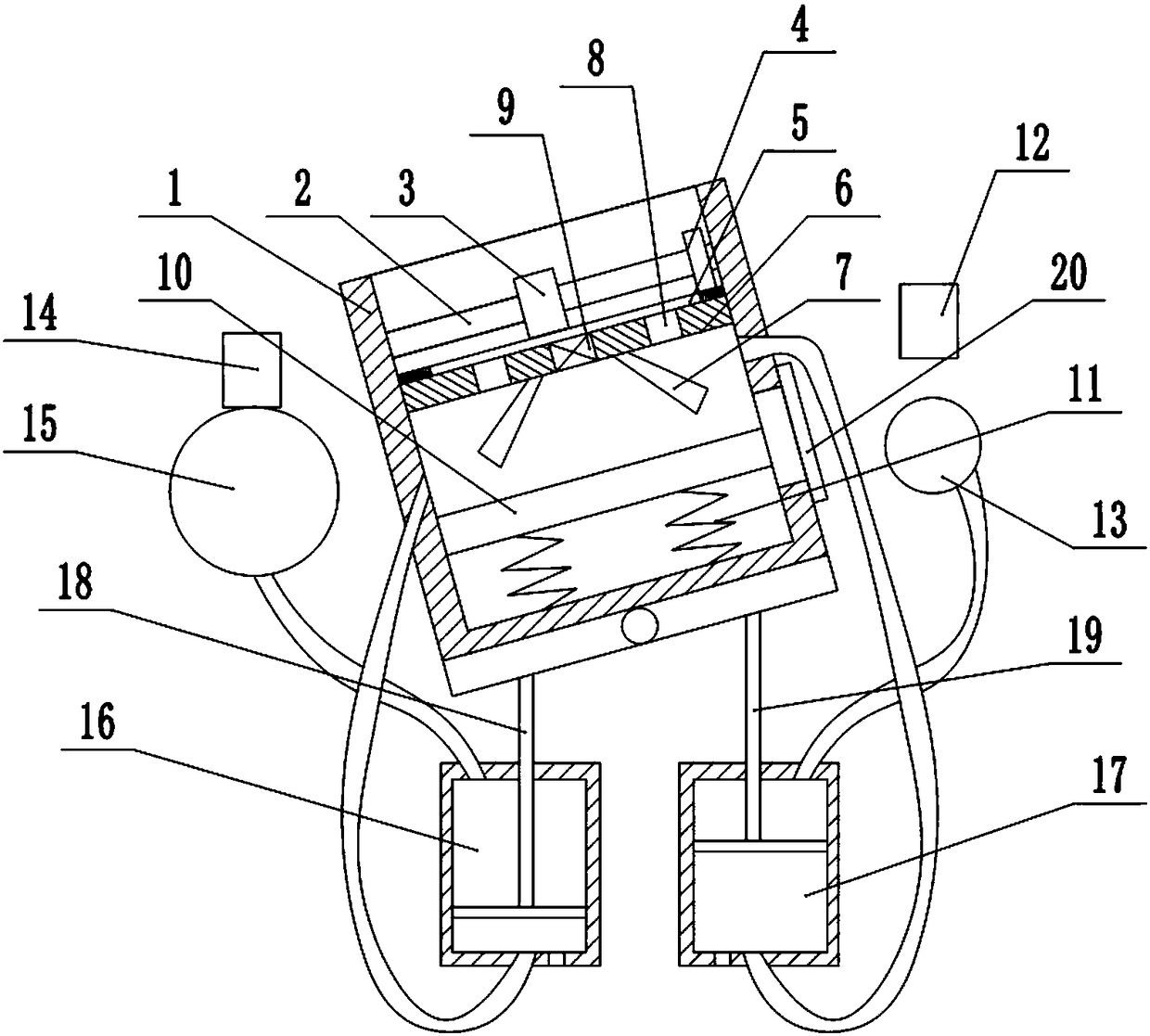

[0021] The reference signs in the drawings of the description include: drying barrel 1, ball screw 2, counterweight 3, gear 4, end gear 5, partition 6, stirring blade 7, through hole 8, first air outlet 9, Skateboard 10, spring 11, second electromagnet 12, second airbag 13, first electromagnet 14, first airbag 15, first piston barrel 16, second piston barrel 17, first piston rod 18, second piston rod 19, baffle plate 20.

[0022] Such as figure 1 As shown, the rice vibrating dryer includes a frame on which a support rod is hinged, and a drying bucket 1 is fixedly connected to the support rod, and the inside of the drying bucket 1 is sequentially connected with a ball screw 2, A partition 6 and a sliding plate 10 are connected in rotation, and a counterweight 3 is threaded on the ball screw 2, and the counterweight 3 is slidably connected with the inner wall of the drying barrel 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com