Multi-layer thermal insulation protection sleeve and application thereof

A technology for protecting casing and heat resistance, which is applied in the direction of protecting pipelines through thermal insulation, pipeline protection, and heat preservation, etc., can solve problems such as explosions, and achieve the effect of improving safety and not easy to burn through.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

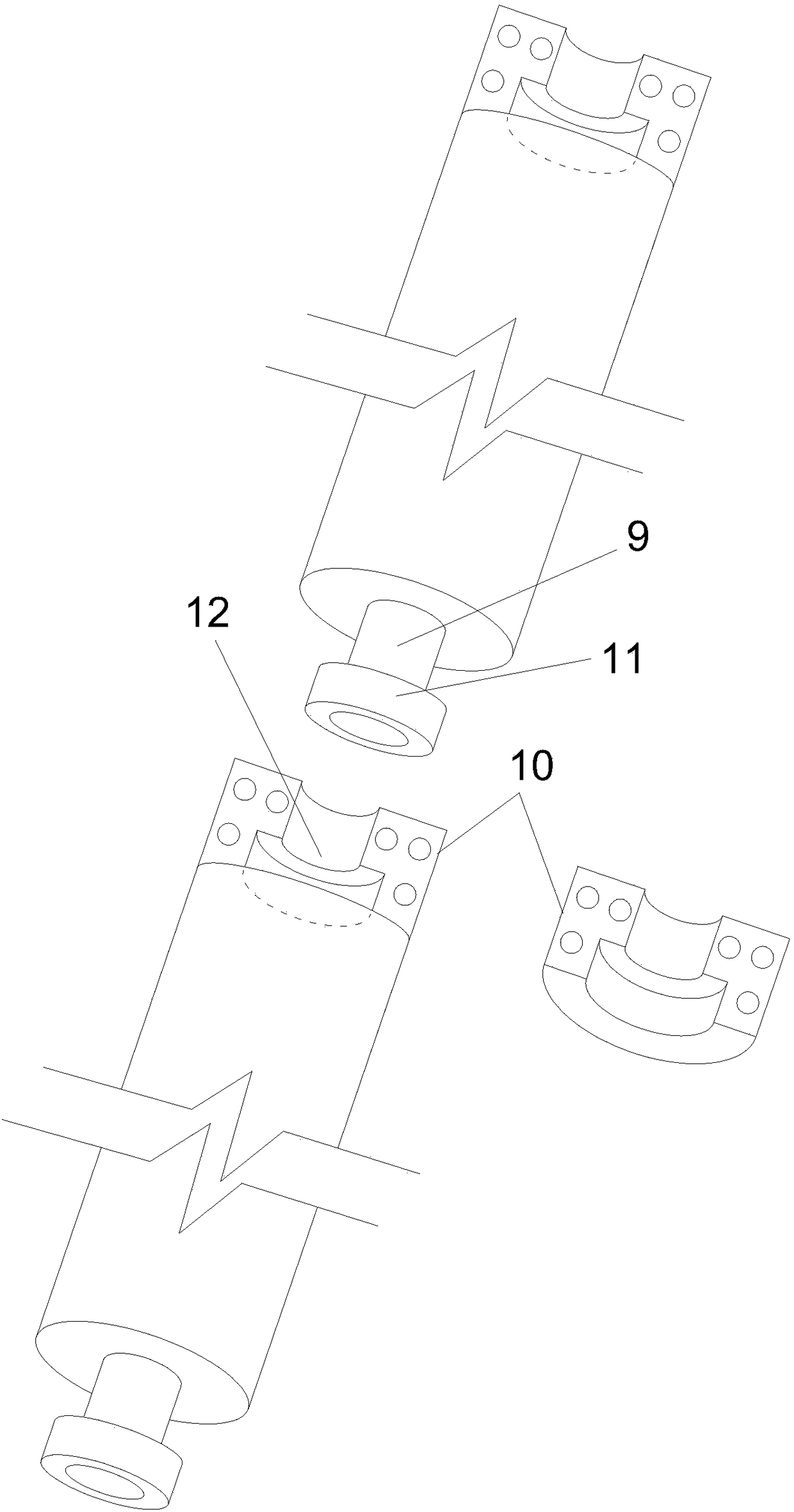

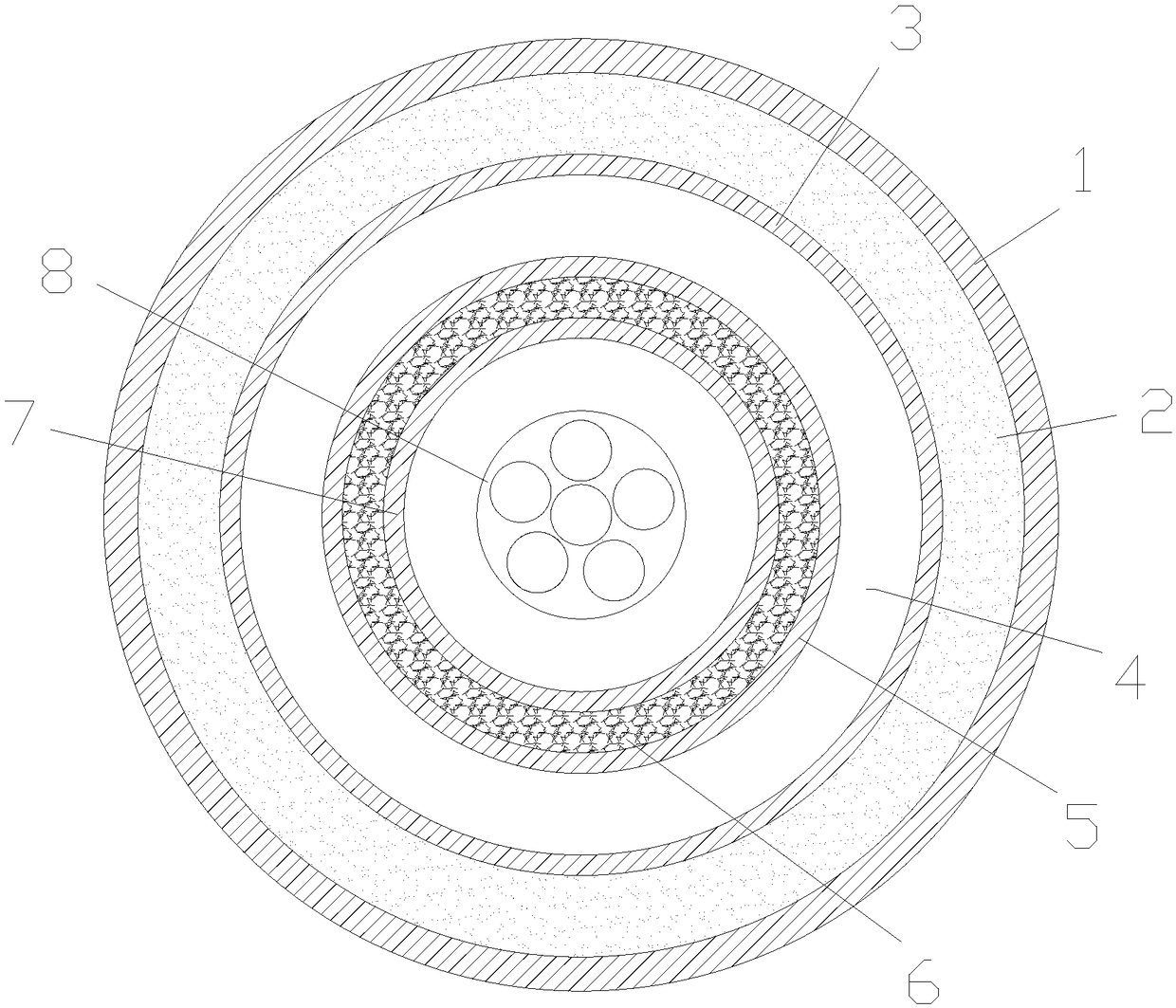

[0022] In order to better understand the present invention, the technical scheme of the present invention will be further described below in conjunction with embodiment and accompanying drawing (as figure 1 , 2 shown).

[0023] Multi-layer heat-resistant protective casing, which includes a stainless steel casing; its feature is that: the pipe wall of the stainless steel casing is the first stainless steel layer 1, the corundum ramming material layer 2, and the second stainless steel layer from outside to inside. Layer 3, vacuum layer 4, third stainless steel layer 5, thermal insulation material layer 6 and fourth stainless steel layer 7.

[0024] The first stainless steel layer 1 is: SUS314 stainless steel with metal composite material added with 5% palladium metal (the first stainless steel layer 1 has high hardness, high oxidation resistance, and is used to protect inner layer structures such as the corundum ramming material layer 2); The second stainless steel layer 3 , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com