Ignition fuel oil flow control method for circled oil supply of auxiliary power unit

An auxiliary power unit, fuel flow technology, applied in engine control, fuel injection control, electrical control, etc., can solve problems such as failure to start, sudden drop in fuel pressure, and deterioration of fuel atomization, and achieve guaranteed ignition, reliable ignition, Good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

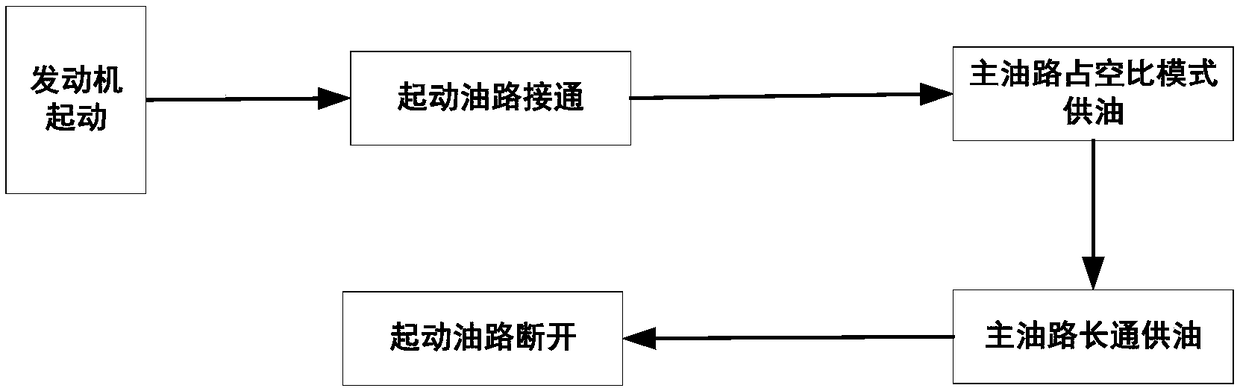

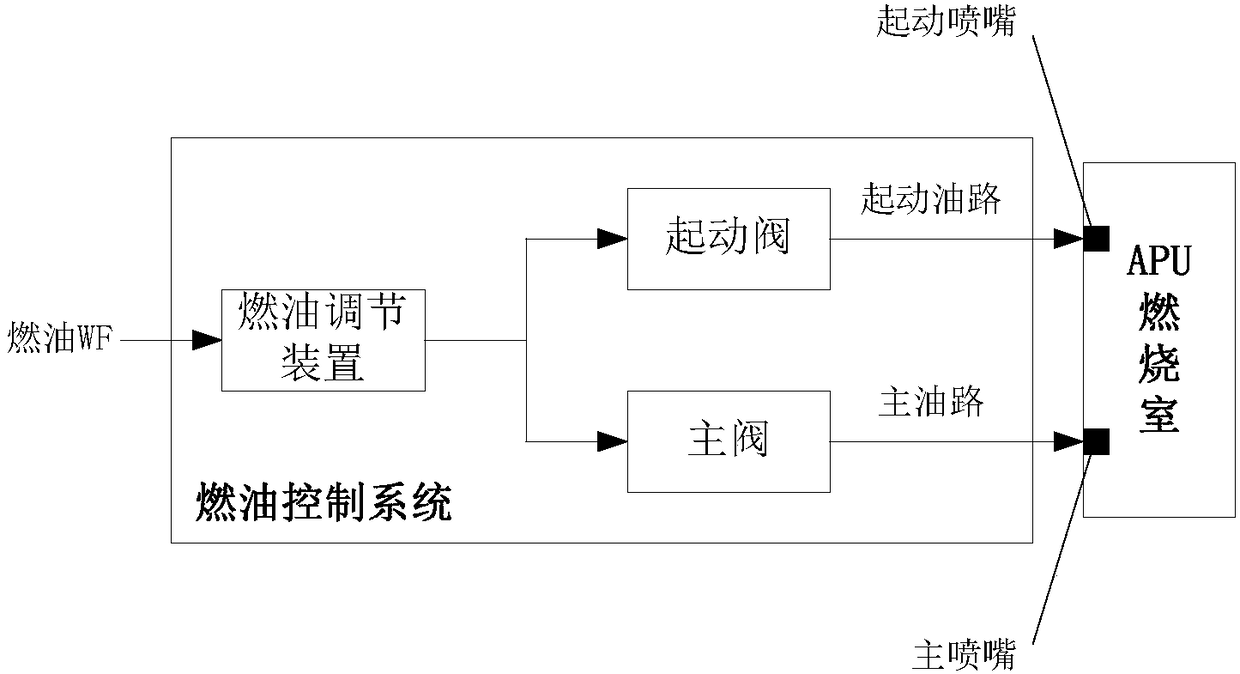

[0028] APU fuel control system such as figure 1 As shown, the fuel regulating device outputs fuel according to the control plan WF=F(NG, P1), and the main valve and the starting valve respectively control the on-off of the main oil circuit and the starting oil circuit. In the formula, NG is the speed of APU, P1 is the inlet pressure of APU, and WF is the fuel flow. In this example, the flow area of the main oil circuit is large, and after the main valve is connected, the fuel pressure drops sharply, and it is very easy to stall.

[0029] The specific implementation steps and related parameters are as follows:

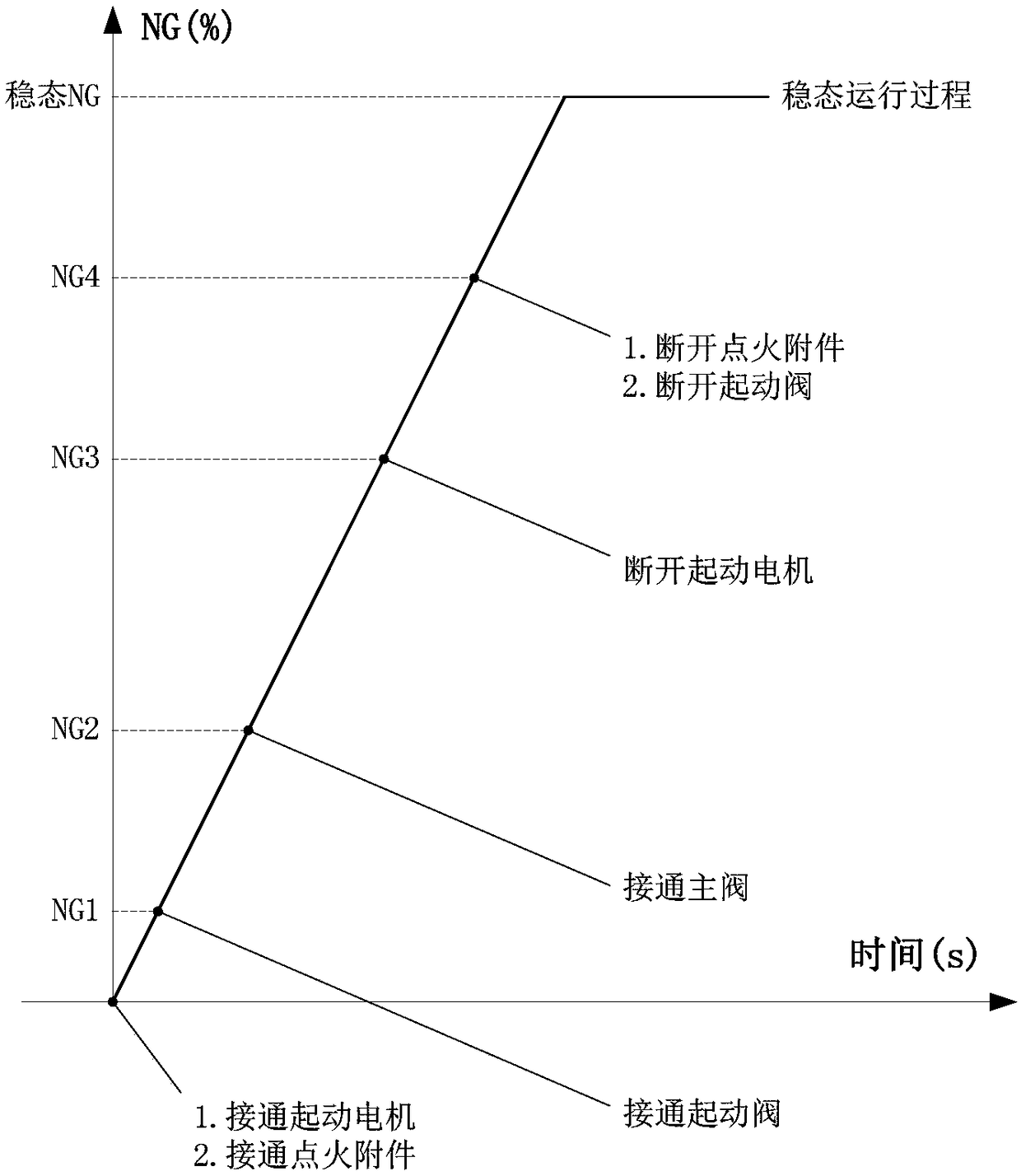

[0030] 1. The APU is in the prohibited state. After receiving the starting command, connect the starter motor and ignition accessories, and the starter motor will turn the APU;

[0031] 2. When the APU speed reaches 3%, record the exhaust temperature at this moment, record it as T40, connect the starting valve, and supply oil according to WF=F(NG, P1);

[0032] 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com