Safety protection system and method for cutting low-pressure cylinder operation of thermal power unit

A thermal power unit and safety protection technology, which is applied to safety devices, mechanical equipment, steam engine devices, etc., can solve problems such as unit shutdown, unreasonable coordination and cooperation, and unreasonable control, so as to reduce unit output, ensure safe shutdown, and increase supply. The effect of heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

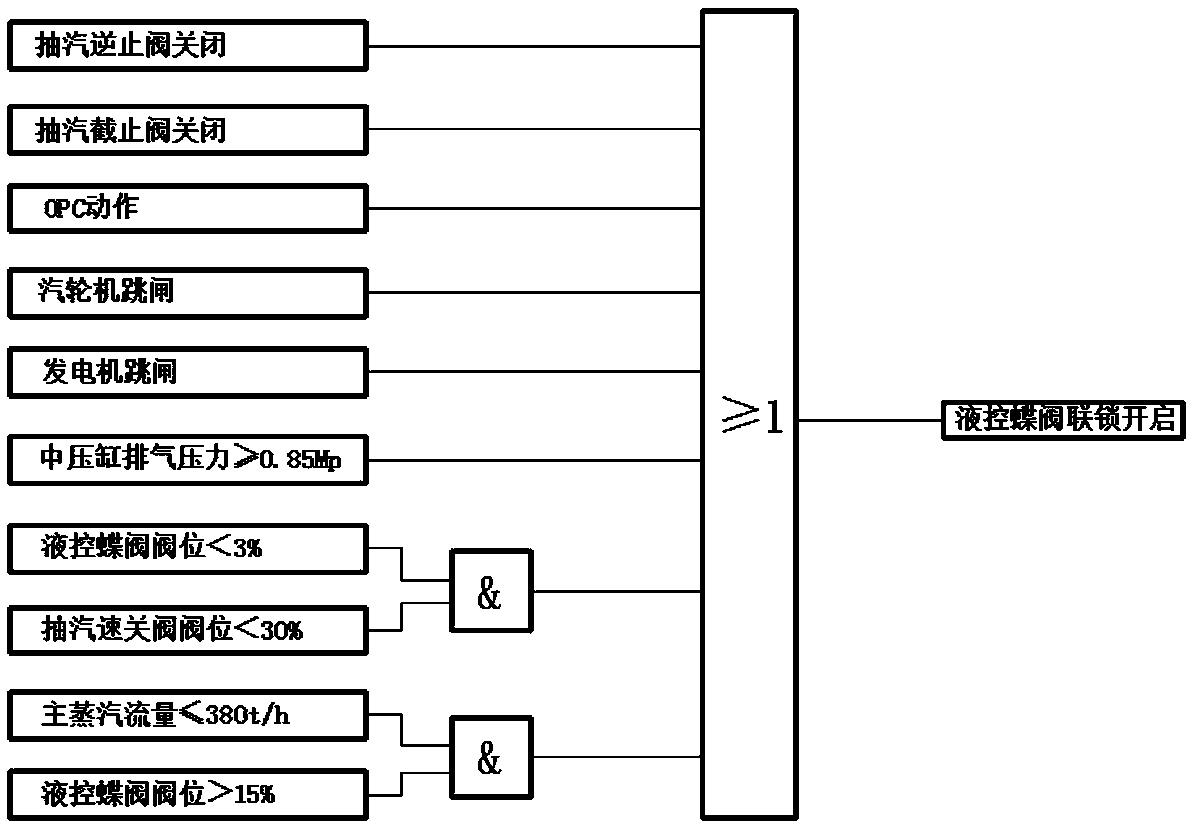

[0056] The present invention will be further explained below in conjunction with the drawings:

[0057] Such as figure 1 As shown, the present invention provides a safety protection system for the operation of a thermal power unit with a low-pressure cylinder cut off, including a thermal power generating set. The boiler outlet of the thermal power generating set is connected with a high-pressure cylinder 32 through a pipeline, and the pipeline connecting the boiler outlet and the high-pressure cylinder 32 is provided with flow metering. The device 22, the main steam valve 6 of the steam turbine and the high pressure regulating valve 7, the exhaust pipe of the high pressure cylinder 32, that is, the inlet pipe of the intermediate pressure cylinder, passes through the boiler and communicates with the intermediate pressure cylinder 33. The inlet pipe of the intermediate pressure cylinder 33 is provided with In the medium pressure regulating valve 8, the medium pressure cylinder 33 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com