Trestle type downhole flow adaptive liquid-liquid separation device

A liquid-liquid separation and self-adaptive technology, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc., which can solve the limitations of high operating conditions of cyclone separation devices, single operating conditions and application scope, and inability to apply To solve problems such as performance, to achieve the effect of simple device structure, efficient separation, and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing:

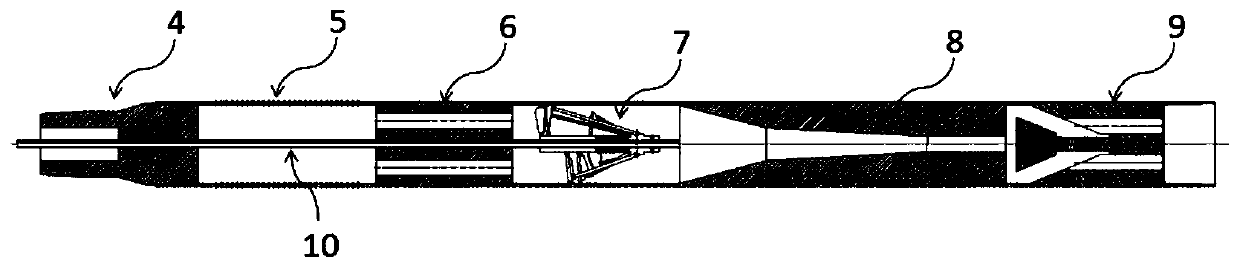

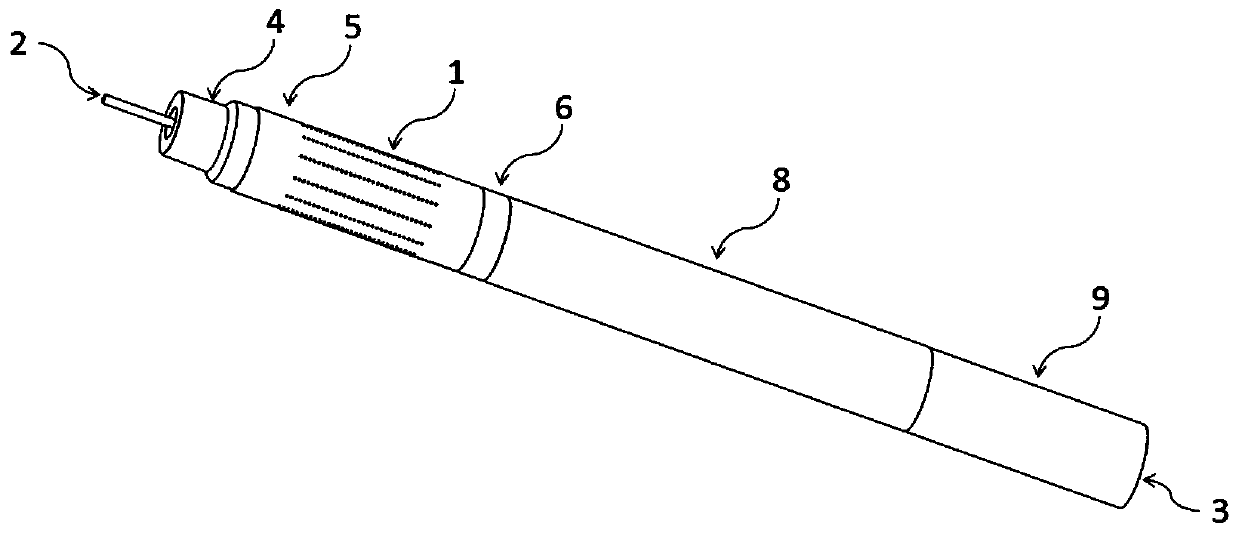

[0051] This trestle type downhole flow self-adaptive liquid-liquid separation device includes a variable diameter joint 4, an inlet pipe 5, a ring type centralizer 6, a trestle type flow stabilization unit 7, a variable diameter separation pipe 8, an overflow pipe 10 and a float type stabilizer. Compressor 9; the top of the overflow pipe 10 is the oil phase outlet 2.

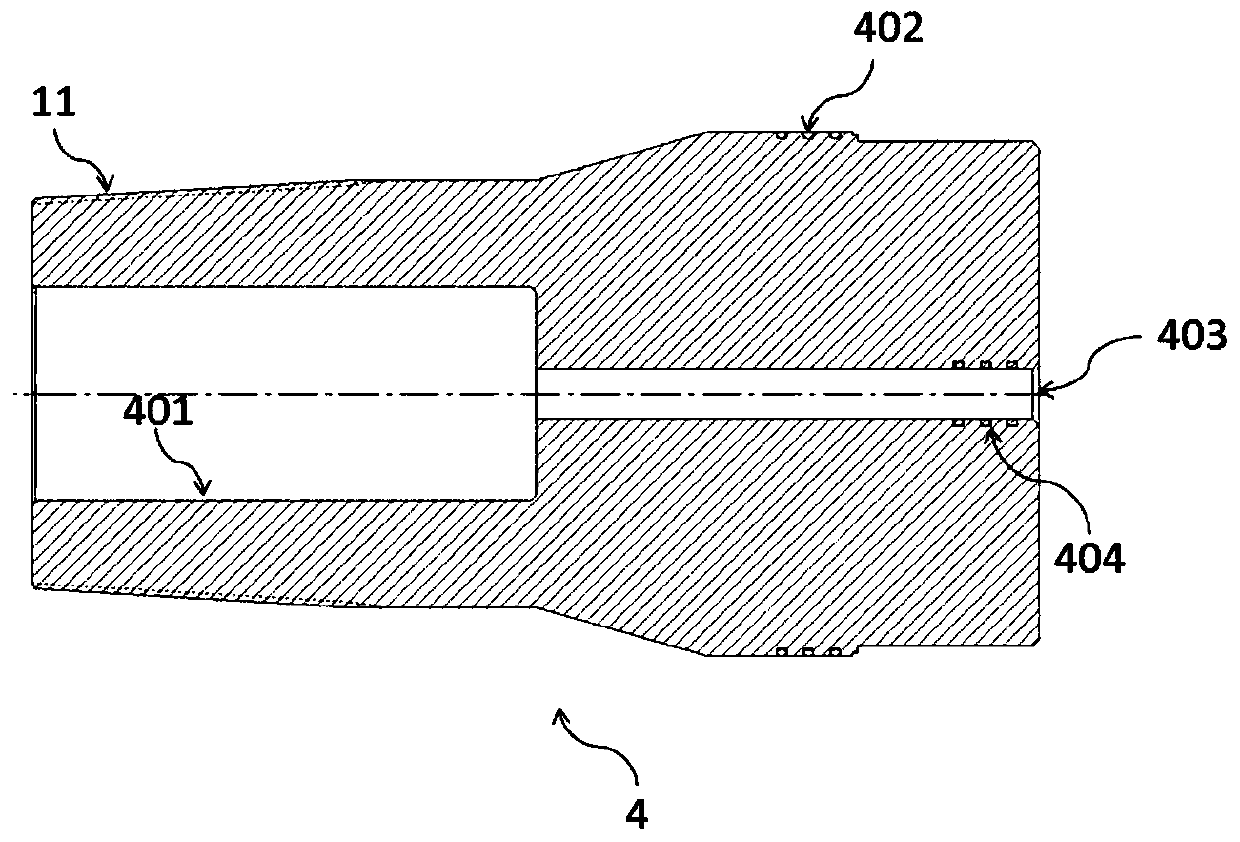

[0052] Among them, the upper end of the variable diameter joint 4 is provided with a pipe taper thread 11 for connecting with the downhole oil pipe, and the lower end is provided with an inlet sealing thread 402 for connecting with the inlet pipe 5, and a through hole is opened in the center, and the overflow pipe 10 runs through this passage. hole; the upper end of the variable diameter joint 4 has an assembly hole 401, and the lower end of the variable diameter joint 4 has a positioning hole 403, and the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com