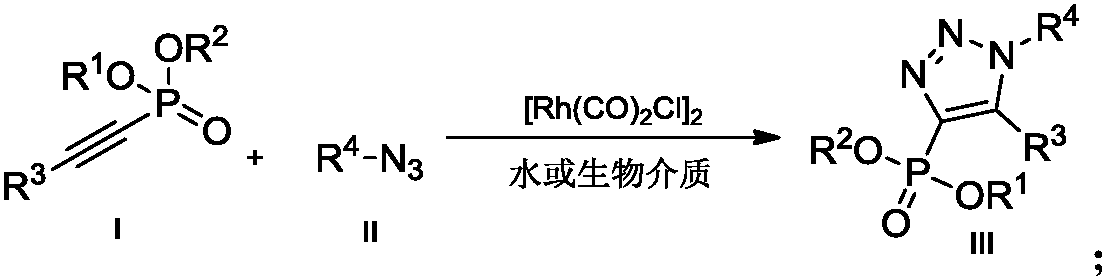

Method for preparing 4-phosphoryl-1,4,5-tri-substituted 1,2,3-triazole in water phase or biomedium

A biological medium and phosphoryl technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of preparation technology that have not been reported publicly, and achieve high reaction efficiency and reaction The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

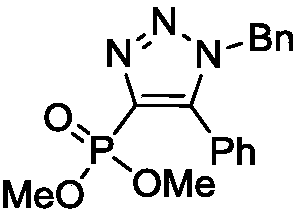

[0020] Example 1: Preparation of 4-phosphodimethyl-(1-benzyl)-5-phenyl-1H-1,2,3-triazole

[0021] Dissolve dimethyl phenylethynyl phosphate (0.2mmol, 42mg) in water (2mL) under air, then add benzyl azide (0.3mmol, 40.2mg) and [Rh(CO) 2 Cl] 2 (0.005mmol, 1.9mg), the reaction mixture was stirred at 40°C and reacted for 12h. After the reaction was completed, it was extracted with ethyl acetate, the solvent was selected to be dry, and the product was separated by column chromatography to obtain 54.9mg of a yellow oily product with a yield of 80%.

[0022]

[0023] 1 H NMR (500MHz, CDCl 3 ,TMS):δ7.50-7.43(m,3H),7.28-7.26(m,5H), 7.03-7.01(m,2H),5.45(s,2H),3.75(s,3H),3.73(s ,3H). 13 C NMR (125MHz, CDCl 3 ):δ143.4(d,J C-P =33.8Hz), 135.0(d, J C-P =241.3Hz), 134.6, 130.3, 129.8, 128.8, 128.7, 128.5, 127.6, 125.4, 53.3 (d, J C-P =6.3Hz), 52.1. 31 P NMR (200MHz, CDCl 3 ): δ9.9. HRMS (ESI) m / z calcdfor C 17 h 18 N 3 o 3 P(M+Na) + 366.0978,found 366.0984.

Embodiment 2

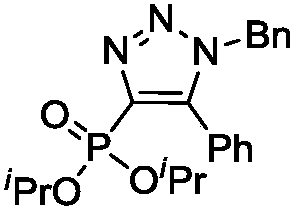

[0024] Example 2: Preparation of 4-diisopropyl phosphate-(1-benzyl)-5-phenyl-1H-1,2,3-triazole

[0025] Under air, diisopropyl phenylethynyl phosphate (0.2mmol, 53.2mg) was dissolved in water (2mL), and benzyl azide (0.3mmol, 40.2mg) and [Rh(CO) 2 Cl] 2 (0.005mmol, 1.9mg), the reaction mixture was stirred at 40°C and reacted for 12h. After the reaction was completed, it was extracted with ethyl acetate, the solvent was selected to be dry, and the product was separated by column chromatography to obtain 67mg of a yellow oily product with a yield of 84%.

[0026]

[0027] 1 H NMR (500MHz, CDCl 3 ,TMS):δ7.47-7.40(m,3H),7.28-7.24(m,5H), 7.02-7.00(m,2H),5.43(s,2H),4.77-4.71(m,2H),1.26 (d,J=10.0Hz,6H),1.16(d,J=10.0Hz,6H). 13 C NMR (125MHz, CDCl 3 ):δ142.6(d,J C-P =32.5Hz), 137.0(d, J C-P =241.3Hz), 134.8, 130.0, 130.0, 128.8, 128.5, 128.3, 127.5, 126.1, 71.6 (d, J C-P =5.0Hz),52.0,24.0(d,J C-P =3.8Hz), 23.6(d, J C-P =3.8Hz). 31 P NMR (200MHz, CDCl 3 ): δ5.5. HRMS (ESI...

Embodiment 3

[0028] Example 3: Preparation of 4-di-n-butyl phosphate-(1-benzyl)-5-phenyl-1H-1,2,3-triazole

[0029] Under air, di-n-butyl phenylethynyl phosphate (0.2mmol, 58.8mg) was dissolved in water (2mL), and benzyl azide (0.3mmol, 40.2mg) and [Rh(CO) 2 Cl] 2 (0.005mmol, 1.9mg), the reaction mixture was stirred at 40°C, and reacted for 12h. After the reaction, it was extracted with ethyl acetate, the solvent was selected to be dry, and the product was separated by column chromatography to obtain 60.6mg of a yellow oily product with a yield of 71%.

[0030]

[0031] 1 H NMR (500MHz, CDCl 3 ,TMS):δ7.48-7.41(m,3H),7.27-7.26(m,5H), 7.03-7.01(m,2H),5.44(s,2H),4.08-4.00(m,4H),1.55 -1.49(m,4H),1.29-1.24(m,4H),0.84(t,J=10.0Hz,6H). 13 C NMR (125MHz, CDCl 3 ):δ142.9(d,J C-P =32.5 Hz), 136.1(d, J C-P=241.3Hz), 134.7, 130.1, 130.0, 128.9, 128.6, 128.4, 127.5, 125.8, 66.5 (d, J C-P =6.3Hz), 52.0, 32.2(d, J C-P =6.3Hz), 18.6, 13.5. 31 P NMR (160MHz, CDCl 3 ): δ7.5. HRMS (ESI) m / z calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com