Method for conditioning sludge through amphoteric polymeric flocculant and biological nano zero-valent iron

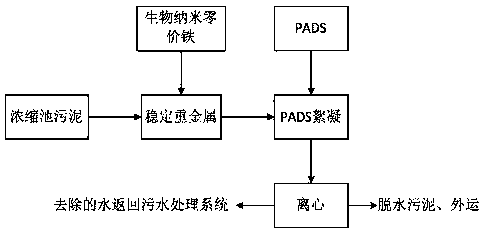

An amphoteric polymer and bio-nano technology, which is used in the field of amphoteric polymer flocculants combined with bio-nano zero-valent iron to adjust sludge, can solve the problems of restricting the utilization of sludge resources, secondary environmental pollution, etc. The effect of wide range, low moisture content and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

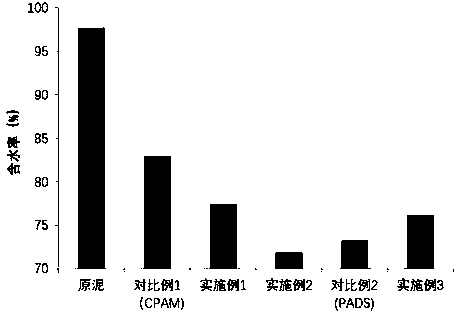

Embodiment 1

[0026] Preparation of bio-nano zero-valent iron suspension: To the dried and crushed grape skin pomace (mixture of grape skin and grape seeds), add 50% ethanol solution Extraction agent: 1 g of grape skin pomace powder is added to extract under the protection of nitrogen, heat and extract in a water bath at 80 °C for 40 min to obtain grape polyphenol extract, and the supernatant obtained by centrifugation at 8000 r / min is the grape polyphenol extract; 2 During the protection, under stirring at 60 r / min, the grape polyphenol extract was added dropwise and mixed in an equal volume of 0.1 M ferrous sulfate solution, and reacted at room temperature for 10 s to obtain a black fresh biological nano iron suspension.

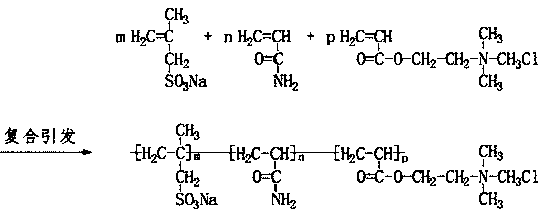

[0027] The preparation method of PADS is as follows: take AM, DAC and SMAS whose mass ratio is 78 / 12 / 10, prepare an aqueous solution with a mass fraction of 10% with distilled water, and pour it into a three-necked flask equipped with a condensation and stirring device; ...

Embodiment 2

[0031] Preparation of bio-nano zero-valent iron suspension: To the dried and crushed grape skin pomace (mixture of grape skin and grape seeds), add 50% ethanol solution Extraction agent: 1 g of grape skin pomace powder is added to extract under the protection of nitrogen, heat and extract in a water bath at 80 °C for 40 min to obtain grape polyphenol extract, and the supernatant obtained by centrifugation at 8000 r / min is the grape polyphenol extract; 2 During the protection, under stirring at 60 r / min, the grape polyphenol extract was added dropwise and mixed in an equal volume of 0.1 M ferrous sulfate solution, and reacted at room temperature for 10 s to obtain a black fresh biological nano iron suspension.

[0032] The preparation method of PADS is: weigh AM, DAC, SMAS with a mass ratio of 80 / 10 / 10, make an aqueous solution with a mass fraction of 10% with distilled water, and pour it into a three-necked flask equipped with a condensation and stirring device; Adjust the pH va...

Embodiment 3

[0037] Preparation of biological nanometer zero-valent iron suspension: Add 50% ethanol solution to the dried and pulverized grape pomace (mixture of grape skin and grape seed) powder Extractant: add 1g of grape pomace powder to extract 20 mL; under the protection of nitrogen, heat and extract in a water bath at 80°C for 40 minutes to obtain grape polyphenol extract, and the supernatant obtained by centrifugation at 8000r / min is the grape polyphenol extract; 2 During protection, under stirring at 60r / min, add the grape polyphenol extract dropwise and mix with a medium volume of 0.1M ferrous sulfate solution, and react at room temperature for 10s to obtain a black fresh bio-nano-iron suspension.

[0038] The preparation method of PADS is: weigh AM, DAC, SMAS with a mass ratio of 90 / 5 / 5, make an aqueous solution with a mass fraction of 10% with distilled water, and pour it into a three-necked flask equipped with a condensation and stirring device; Adjust the pH value of the aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com