A biological carrier for coking wastewater biochemical system treatment and its application

A technology of biological carrier and coking wastewater, which is applied in the treatment of granular microbial carriers, natural water body treatment, and multi-stage water/sewage treatment to achieve the effect of promoting production, lowering production cost and improving treatment capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

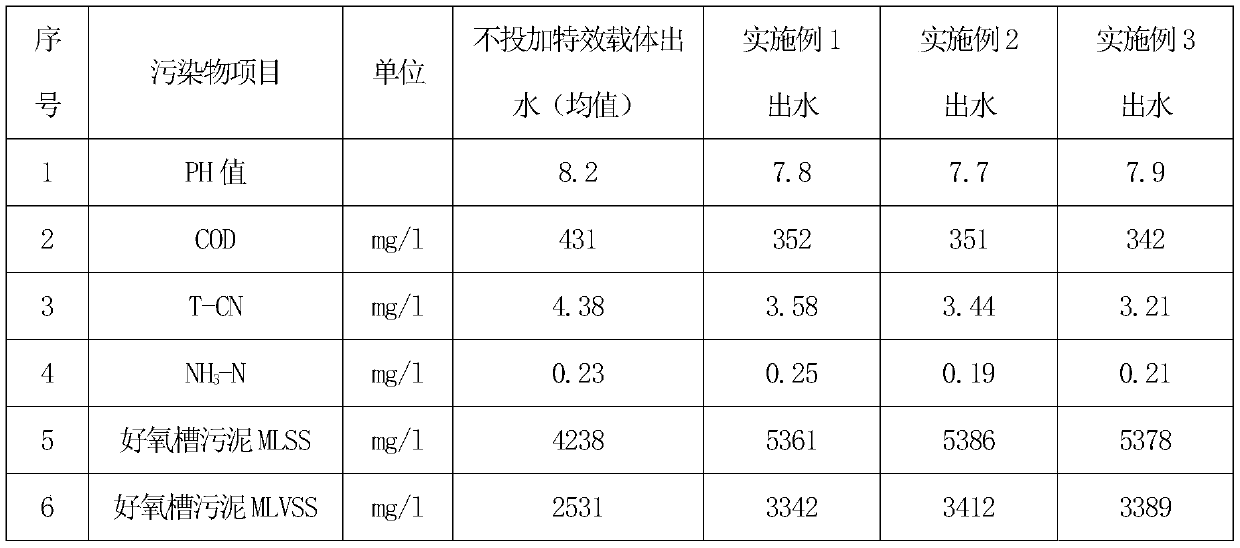

Embodiment 1

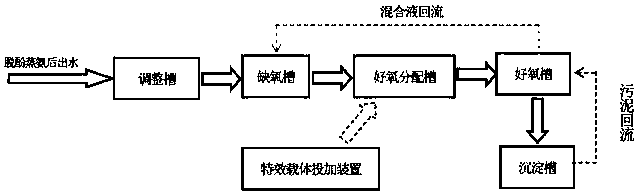

[0055] 1. After the ammonia distillation treatment, the effluent is pumped to the adjustment tank by the ammonia distillation effluent pump. The raw water quality: pH is 7.8, COD is 2250mg / l, phenol is 65mg / l, ammonia nitrogen is 220mg / l, oil is 16mg / l , T-CN is 12mg / l, and the water temperature is 28°C.

[0056] 2. The effluent from the adjustment tank is pumped to the anoxic tank through the transfer pump, and the water in the anoxic tank is treated with two parts: one part is the effluent from the adjustment tank, and the other part is the reflux mixture from the aerobic tank. The ratio of the effluent from the adjustment tank to the reflux mixture is 1:3, the effluent from the anoxic tank overflows to the aerobic distribution tank.

[0057] 3. The effluent from the anoxic tank flows into the aerobic distribution tank through the overflow, and the special-effect carrier and pure water are mixed into a slurry with a concentration of 10% through the powder dosing device, and ...

Embodiment 2

[0060] 1. After the ammonia distillation treatment, the effluent is pumped to the adjustment tank by the ammonia distillation effluent pump. The raw water quality: pH is 7.5, COD is 2050mg / l, phenol is 70mg / l, ammonia nitrogen is 200mg / l, oil is 15mg / l , T-CN is 10mg / l, and the water temperature is 29°C.

[0061] 2. The effluent from the adjustment tank is pumped to the anoxic tank through the transfer pump, and the water in the anoxic tank is treated with two parts: one part is the effluent from the adjustment tank, and the other part is the reflux mixture from the aerobic tank. The ratio of the effluent from the adjustment tank to the reflux mixture is 1:3, the effluent from the anoxic tank overflows to the aerobic distribution tank.

[0062] 3. The effluent from the anoxic tank flows into the aerobic distribution tank through the overflow, and the special-effect carrier and pure water are mixed into a slurry with a concentration of 10% through the powder dosing device, and ...

Embodiment 3

[0067] 1. After the ammonia distillation treatment, the effluent is pumped to the adjustment tank by the ammonia distillation effluent pump. The raw water quality: pH is 8.2, COD is 2540mg / l, phenol is 62mg / l, ammonia nitrogen is 205mg / l, oil is 17mg / l , T-CN is 16mg / l, and the water temperature is 30°C.

[0068] 2. The effluent from the adjustment tank is pumped to the anoxic tank through the transfer pump, and the water in the anoxic tank is treated with two parts: one part is the effluent from the adjustment tank, and the other part is the reflux mixture from the aerobic tank. The ratio of the effluent from the adjustment tank to the reflux mixture is 1:3, the effluent from the anoxic tank overflows to the aerobic distribution tank.

[0069] 3. The effluent from the anoxic tank flows into the aerobic distribution tank through the overflow, and the special-effect carrier and pure water are mixed into a slurry with a concentration of 10% through the powder dosing device, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com