Preparation method and application of phase-controllable manganese oxide

An oxide and phase technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, manganese oxide/hydroxide, etc., can solve the problems of complex preparation process, consumption of large chemical substances and energy, etc., and achieve rich sources. , low cost, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Five comparison experiments were set up: under the condition of 60ml water as solvent, 5mmol manganese chloride tetrahydrate provided manganese source, the amount of added carbon source glucose was 0mmol, 5mmol, 10mmol, 15mmol, 20mmol respectively, and in the presence of 100mmol urea , placed in a polytetrafluoroethylene-lined autoclave for hydrothermal reaction, centrifuged, washed and dried to obtain manganese carbonate@carbon composites.

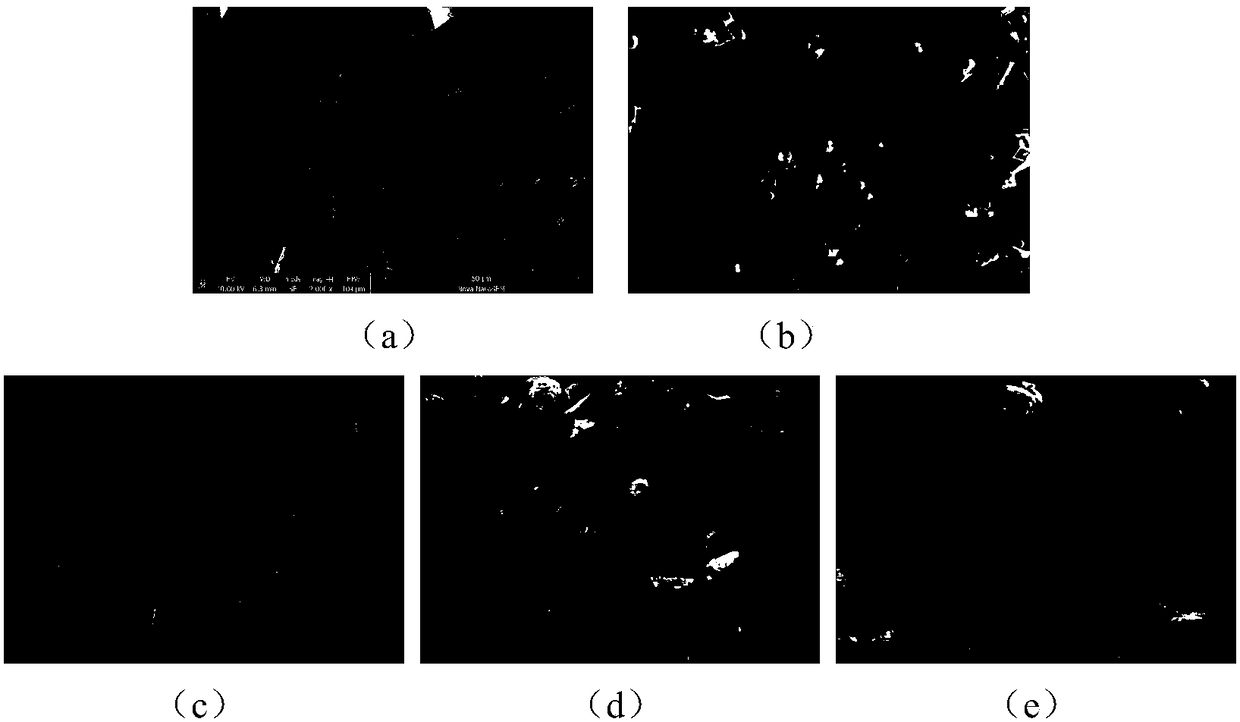

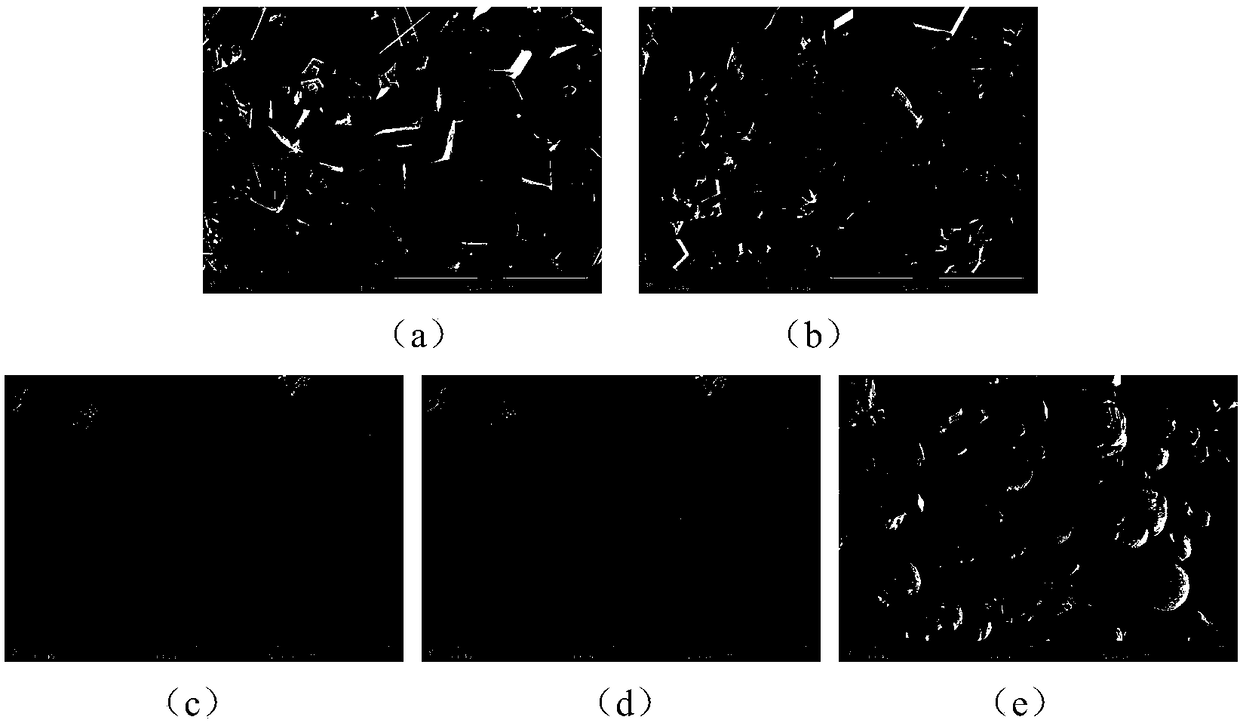

[0037] figure 1 In (a) is the sample MnCO prepared without adding glucose 3 The scanning electron microscope figure, (b)-(e) is the preparation precursor MnCO of adding different content glucose in embodiment 1 3 SEM image of @C. from figure 1 It can be seen that the morphology of the manganese carbonate@carbon composite material is clearly visible. By comparing the graphs (a) and (b-e), it can be seen that the increase in the amount of glucose changes the morphology of the composite material, and some square structures A spheri...

Embodiment 2

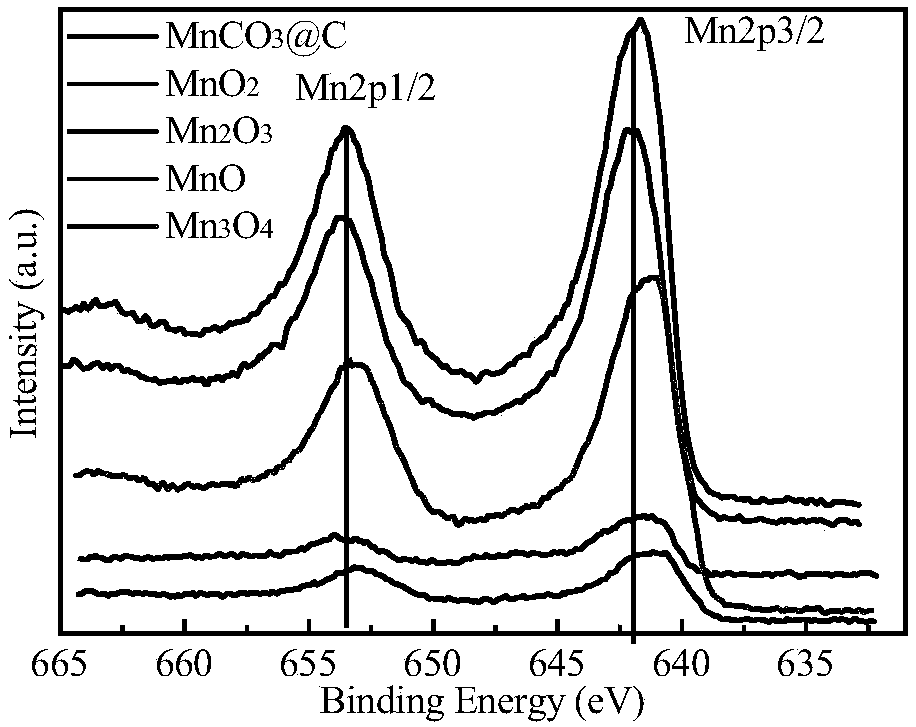

[0041] Under the condition of 60ml of water as solvent, 5mmol of manganese chloride tetrahydrate provides manganese source, 15mmol of glucose provides carbon source, and under the condition of 100mmol of urea, it is hydrothermally reacted in a high-pressure reactor lined with polytetrafluoroethylene , Manganese carbonate@carbon composites were obtained by centrifugation, washing and drying. The precursor composite was placed in a porcelain ark and pyrolyzed in a tube furnace. Under air conditions, the temperature is 500°C, the heating rate is 3°C / min, and the temperature is kept for 5 hours to obtain manganese trioxide.

Embodiment 3

[0043] Under the condition of 60ml of water as solvent, 5mmol of manganese chloride tetrahydrate provides manganese source, 15mmol of glucose provides carbon source, and under the condition of 100mmol of urea, it is hydrothermally reacted in a high-pressure reactor lined with polytetrafluoroethylene , Manganese carbonate@carbon composites were obtained by centrifugation, washing and drying. The precursor composite was placed in a porcelain ark and pyrolyzed in a tube furnace. Under the condition of nitrogen protection, the temperature is 500°C, the heating rate is 3°C / min, and the temperature is kept for 5h to obtain manganese monoxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com