Operation device for mixed material

A technology of operation device and unloading device, applied in the field of mechanical transmission, can solve the problems of poor work continuity and difficult to guarantee the accuracy of feeding amount, etc., and achieve the effect of improving compactness, reducing equipment complexity and accurate feeding amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

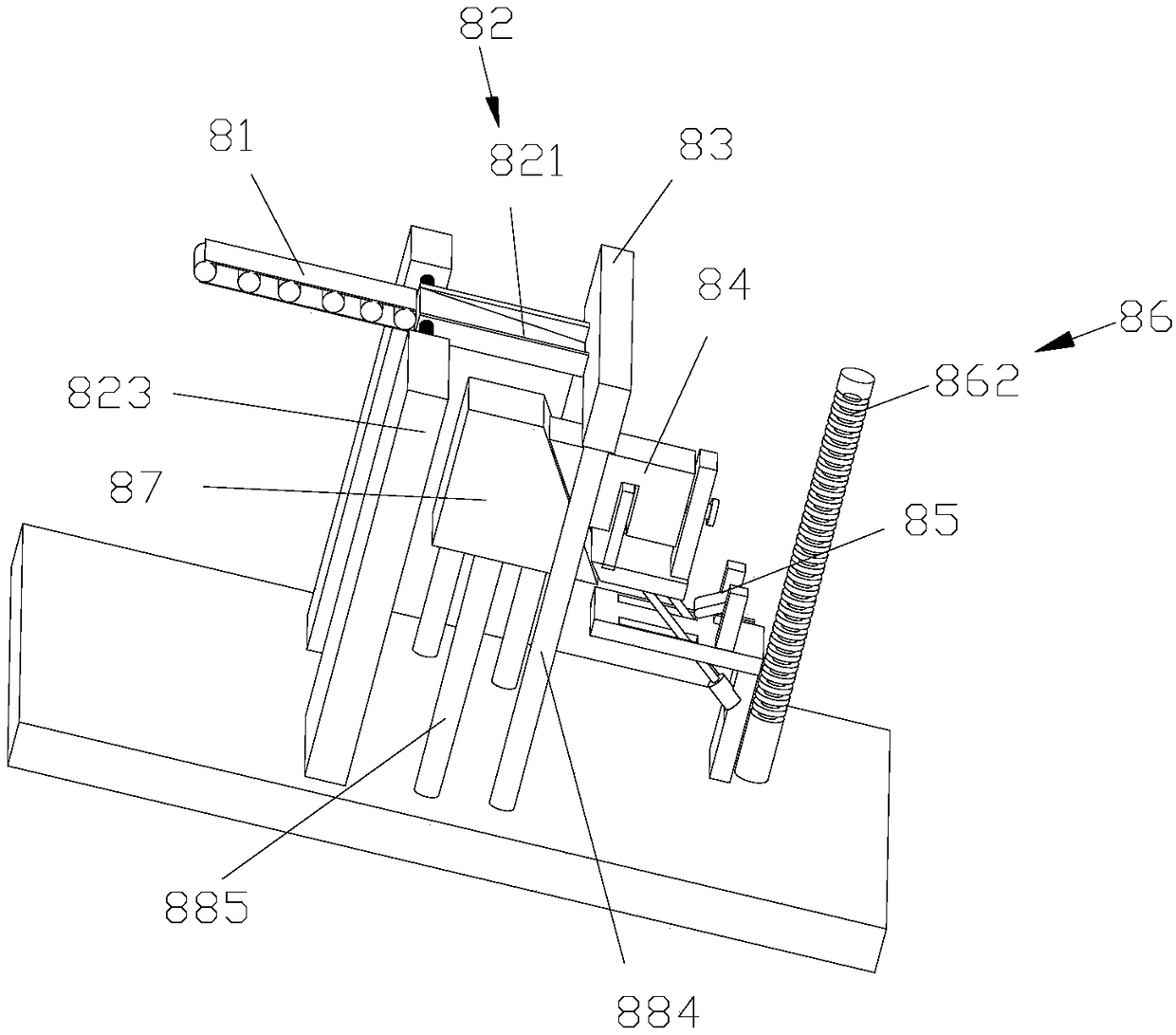

[0038] Such as Figure 1-2 As shown, the present invention discloses a mixed material running device, which includes a running conveyor belt 81, a flipping unloading device 82, a running baffle 83, a hopper 84, a running elastic device 85, and a running lifting device arranged sequentially from front to back. Abutment 86. The running conveyor belt 81 is used to convey the material to the turning-type unloading device 82 , and the running baffle 83 is in contact with the end of the upper turning-type unloading device 82 to confine the material in the turning-type unloading device 82 . The running baffle 83 of the present invention is supported by the fourth running frame 884 . The hopper 84 is located below the turning-type unloading device 82 , and the turning-type unloading device 82 rotates clockwise to discharge the materials therein into the hopper 84 . Also comprise operation guide table 87, the bottom of operation guide table 87 is supported by the 5th operation frame ...

Embodiment 2

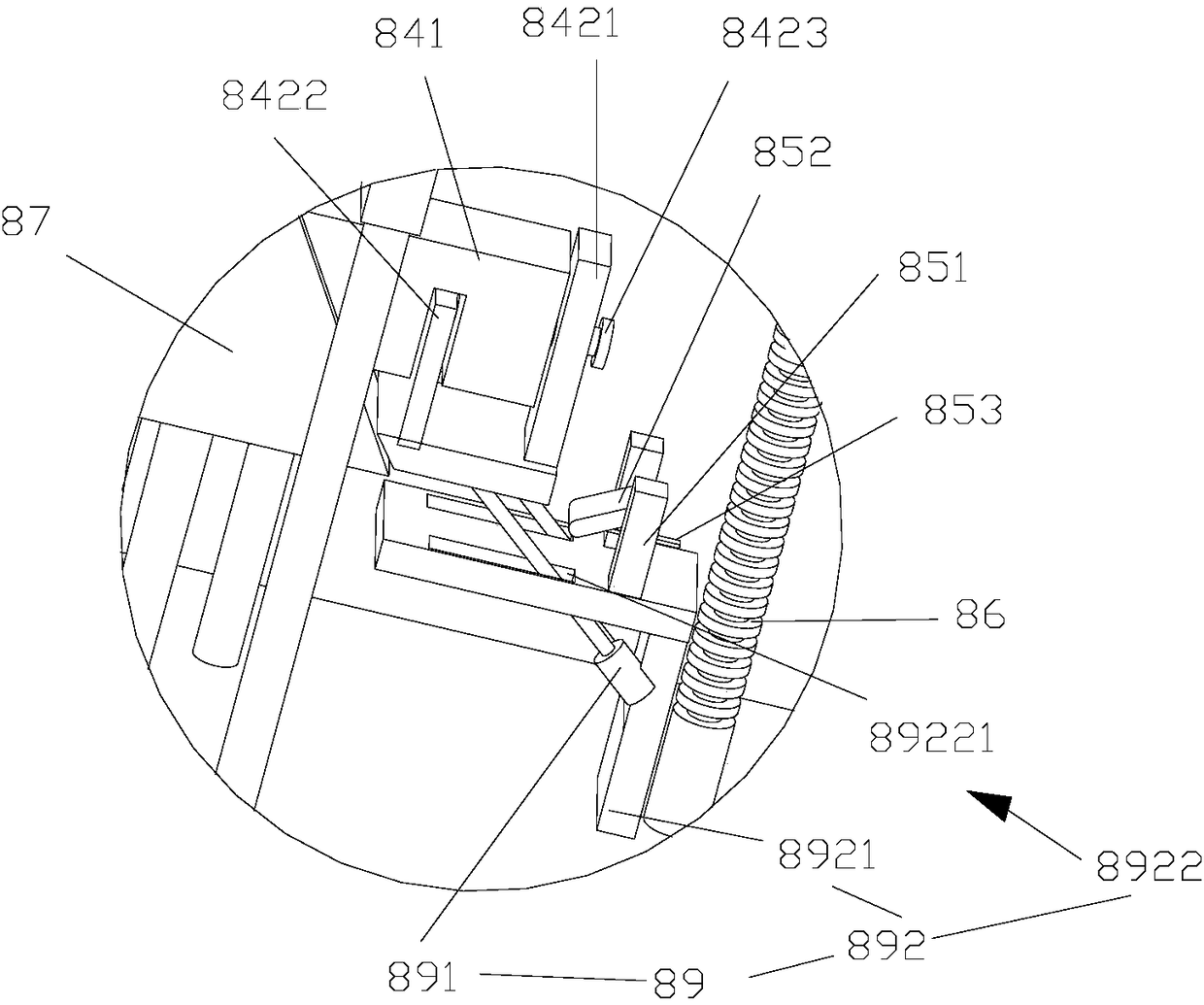

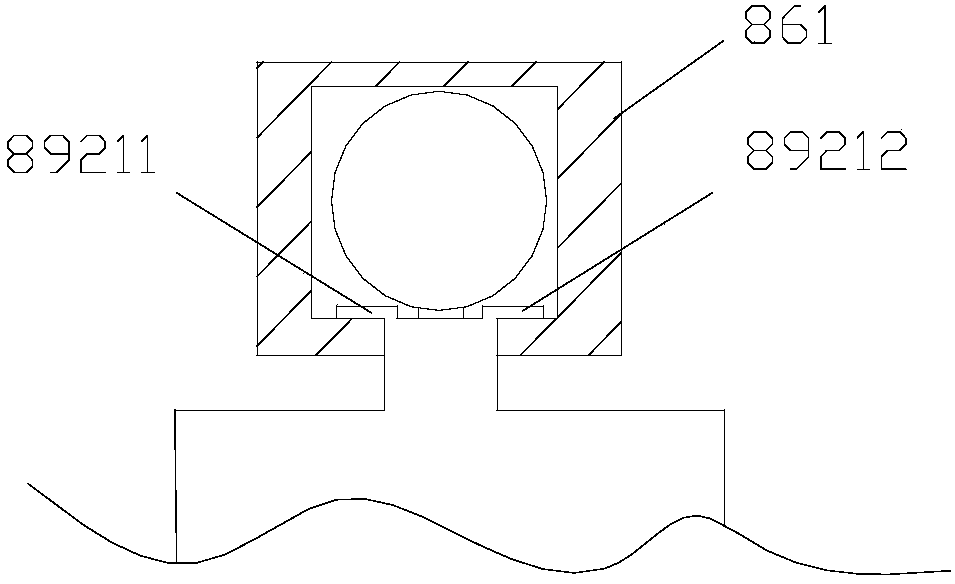

[0042] Such as figure 1 , 5 As shown in -7, the difference between this embodiment and the above-mentioned embodiments is that: the flip-type unloading device 82 includes a running loading plate 821, a first running shaft 822, a first running frame 823, a first running torsion spring 824, and running The front end of the loading plate 821 is hinged with the first running shaft 822, the first running shaft 822 is arranged on the first running frame 823, and the first running torsion spring 824 is connected to the first running frame 823 and the bottom of the running charging plate 821. Between the front ends, the first running torsion spring 824 is assembled so that the rear end face of the running charging plate 821 is against the front end face of the running baffle plate 83; the running charging plate 821 includes a running bottom plate 8211 and two running side plates 8212 , the running bottom plate 8211 and two running side plates 8212 are surrounded by a structure with a...

Embodiment 3

[0046] Such as figure 2 , 4 , shown in 6, the difference between the present embodiment and the above-mentioned embodiment is: the operation elastic device 85 comprises the second operation frame 851, the operation connecting plate 852, the operation protrusion 853, the second operation torsion spring 854, the second operation rotating shaft ( not shown in the figure). The second running shaft is arranged on the second running frame 851, the upper end of the running connecting plate 852 is hinged with the second running rotating shaft, and the second running torsion spring 854 is connected between the second running frame 851 and the upper end of running connecting plate 852 , the lower end of the running connecting plate 852 extends toward the direction of the hopper 84 , and the running protrusion 853 is mounted on the running connecting plate 852 . The oblique downward movement of the hopper 84 can drive the running connecting plate 852 to rotate until the running protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com