Mixing device of industrial tail gas purifying agent

A mixing device and industrial tail gas technology, which is applied in the direction of mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problems of affecting the effect of tail gas purification, solution confusion, and out-of-control input ratio, so as to achieve convenient continuous work, convenient use, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

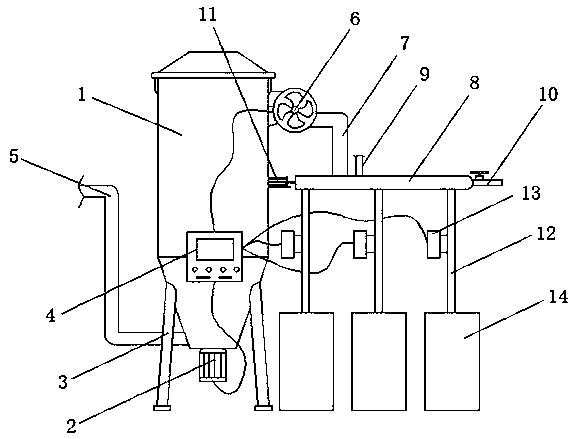

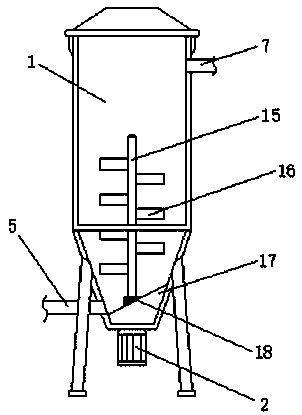

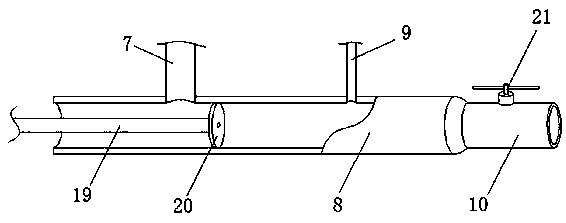

[0019] see Figure 1-2 Shown, a kind of mixing device of industrial tail gas purification agent comprises mixing barrel 1, liquid outlet pipe 5 and liquid inlet pipe 7, and the bottom end side wall of liquid outlet pipe 5 and mixing barrel 1 is pipeline connection, and liquid inlet pipe 7 and The top side wall of the mixing tank 1 is connected by pipelines, and the liquid inlet pipe 7 is controlled by the water pump 6 to pump liquid, the bottom of the mixing tank 1 is equipped with a motor 2, and the output end of the motor 2 is connected with the stirring rod 16 inside the mixing tank 1, The outer wall of the stirring rod 16 is welded with several stirring blades 16; one side of the mixing bucket 1 is placed on the ground with several reagent buckets 14, and the top of the reagent buckets 14 is connected to the suction pipe 12, and the several suction pipes 12 are all connected to the buffer tank 8. connected to each other, and a flow controller 13 is installed on the outer w...

Embodiment 2

[0021] In addition, refer to Figure 1-3 The outer wall of the mixing bucket 1 is equipped with a PLC controller 4, and the bottom of the mixing bucket 1 is welded with several supporting legs 3, and the supporting legs 3 support the mixing bucket 1 without shaking, and the PLC controller 4 is connected with the motor 2, the water pump 6, and the electric pusher Rod 11 is connected with flow controller 13, and the work of controlling motor 2, water pump 6, electric push rod 11 and flow controller 13 by PLC controller 4 can be more convenient. The output end of the motor 2 passes through the sealing ring 18 embedded in the slope bottom 17 and is connected to the stirring rod 15. The slope bottom 17 prevents the mixed cleaning agent inside the mixing bucket 1 from accumulating at the bottom of the bucket, and the sealing ring 18 prevents the mixed cleaning agent from flowing from the motor. The output end of 2 leaks out of the mixing tank 1, and the position of the end of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com