Load-deflection resistance side pressing cylinder device

An anti-eccentric load and side-holding cylinder technology is applied in the field of hydraulic presses, which can solve the problems that the side-holding cylinder does not have anti-eccentric load measures, increased production and maintenance costs, hidden safety hazards, etc., so as to facilitate continuous work, reduce safety hazards, and increase use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

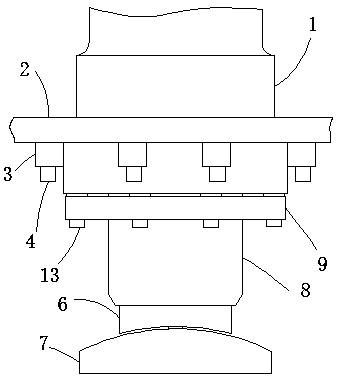

[0023] The anti-bias load side cylinder device includes a fixed frame 2, an oil cylinder body 1, a plunger rod 8 and a guide copper sleeve 15. The lower end of the oil cylinder body 1 is provided with an opening, and the upper end of the plunger rod 8 passes through the opening and connects with the oil cylinder body 1. The inner wall of the plunger rod 8 is slidingly socketed, and the lower end of the plunger rod 8 is provided with a cylindrical groove, and an anti-eccentric load mechanism is provided in the cylindrical groove, and the plunger rod 8 is connected with the lower spherical pad 7 through the anti-eccentric load mechanism. The inner edge is provided with an annular slot, and the oil cylinder body 1 is engaged with the outer wall of the guide copper sleeve 15 through the annular slot. The guide copper sleeve 15 and the annular slot are in an interference connection. The oil groove 16, the lubricating oil groove 16 and the rod wall of the plunger rod 8 jointly form a...

Embodiment 2

[0026] Embodiment 2: the difference based on Embodiment 1 is;

[0027] The anti-bias load mechanism includes an annular block 6 fixed on the lower end of the plunger rod 8. The opening edge of the lower end of the annular block 6 is provided with a concave surface matching the upper end of the lower spherical pad 7, and the center of the lower end of the lower spherical pad 7 is provided with a hemispherical concave. Groove, the first hemisphere 10 is slidingly connected in the hemispherical groove, the upper center of the first hemisphere 10 is screwed with the pull rod 20 through the first threaded hole, and the transition sleeve 11 is fixedly connected in the cylindrical groove, and the transition sleeve 11 The inner side is a frustum-shaped structure. The upper end of the pull rod 20 passes through the annular block 6 and the transition sleeve 11 and is sleeved with a spring 12 and an annular gasket 18. The upper end of the pull rod 20 is threaded with a nut 17 through an e...

Embodiment 3

[0030] Embodiment 3: the difference based on embodiment 1 is;

[0031]The sealing mechanism includes a sealing pressure ring 9 slidingly sleeved on the wall of the plunger rod 8. The lower end edge of the sealing pressure ring 9 is slidably sleeved with a plurality of fixing bolts 13 through through holes, and the lower end edge of the oil cylinder body 1 is through multiple bolts. A second threaded hole is threadedly connected with a plurality of fixing bolts 13 respectively, and the inner opening of the upper end of the sealing pressure ring 9 is provided with a positioning slot matched with the lower end of the guide copper sleeve 15, and the inner edge of the lower end opening of the guide copper sleeve 15 A sealing ring 14 is embedded, and the inner side of the sealing ring 14 is slidingly socketed with the rod wall of the plunger rod 8 .

[0032] The upper end of the sealing pressure ring 9 is provided with a plurality of adjusting washers 21, and the plurality of adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com