Flue gas dust removal process

A flue gas and process technology, which is applied in the field of waste gas treatment process, can solve the problems of easy clogging of cloth bags and poor dust removal effect, and achieve good dust removal effect and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

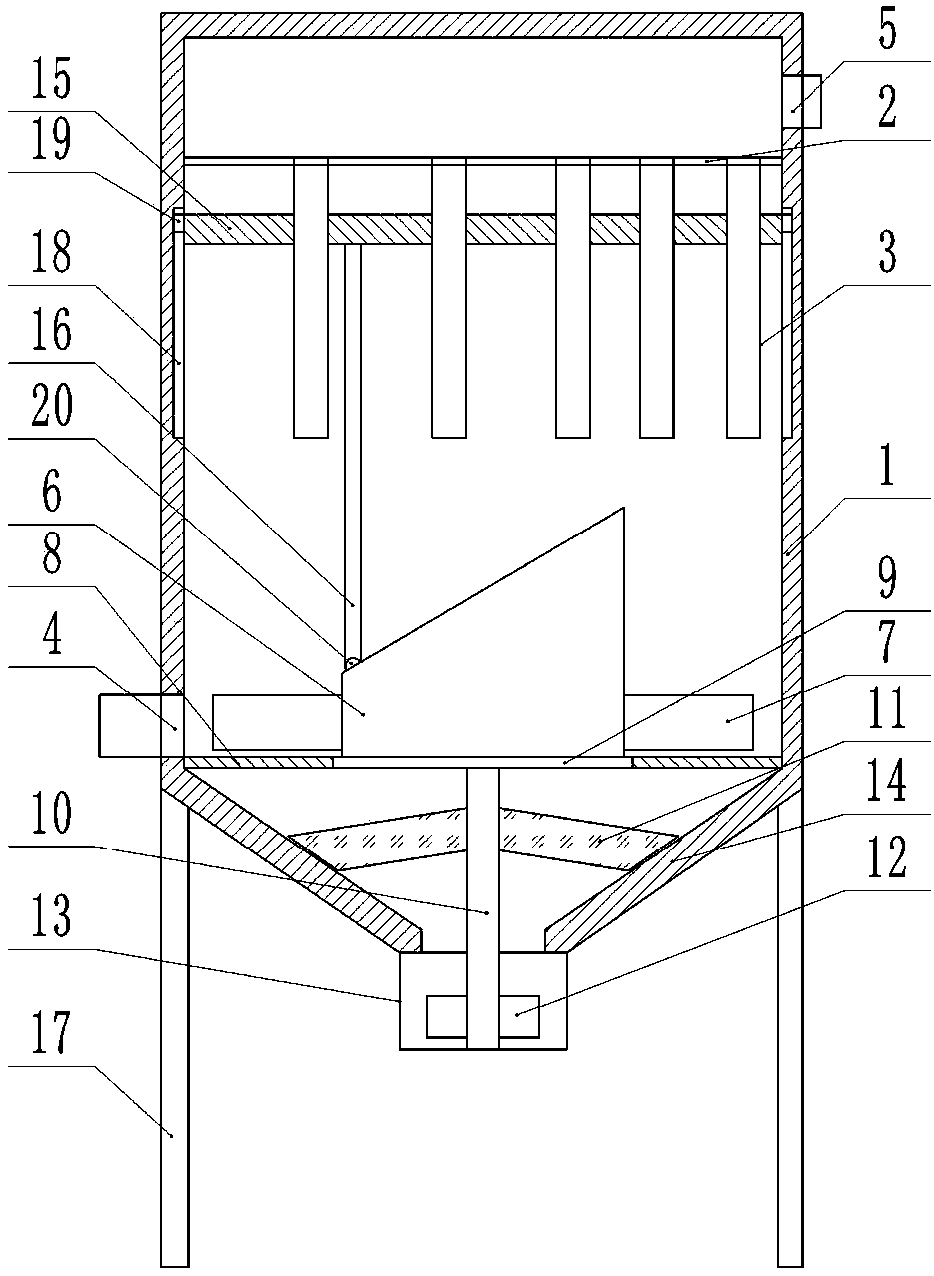

[0023] The reference signs in the drawings of the specification include: box body 1, flower plate 2, cloth bag 3, air inlet 4, air outlet 5, pillar platform 6, fan blade 7, support rod 8, support frame 9, rotating shaft 10, brush plate 11. Pushing plate 12, material guiding cylinder 13, ash hopper 14, pushing plate 15, ejector rod 16, bracket 17, vertical groove 18, fixed block 19.

[0024] like figure 1 and figure 2 As shown, a flue gas dedusting process includes the following process steps:

[0025] (1) Pass the flue gas produced by the electric furnace into the cooler, and the flue gas cools down in the cooler to discharge water;

[0026] (2) Pass the flue gas in the cooler into the bag filter through the induced draft fan. After the flue gas passes through the bag filter to remove dust, the flue gas after dust removal passes through the integrated tower of dust removal, desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com