Hopkinson press rod system with true triaxial dynamic loading and testing functions and method

A technology of dynamic loading and testing functions, applied in the testing/calibration of velocity/acceleration/shock measurement equipment, velocity/acceleration/shock measurement, measurement devices, etc., which can solve the problems of dynamic calibration, difficult decoupling, and synchronization of shock wave structure It can solve the problems of complex shape consistency, etc., to achieve the effect of wide range of applications, high measurement accuracy, and avoidance of decoupling structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

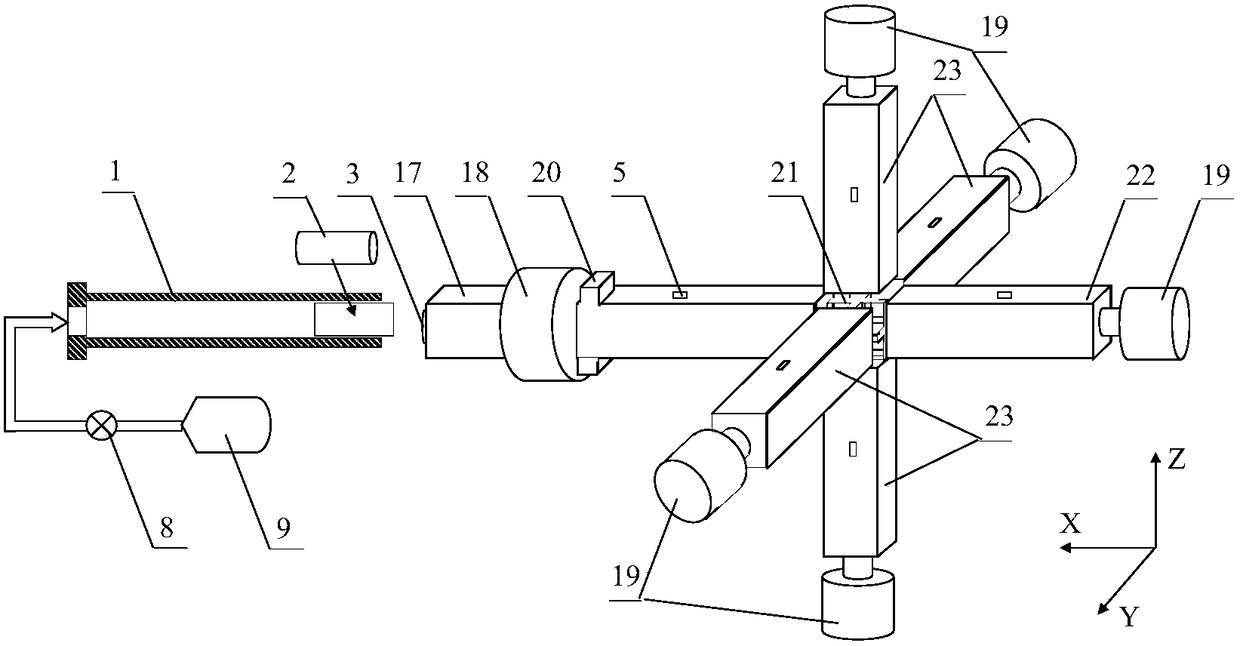

[0034] refer to image 3 and Figure 4 , the present invention adopts the square prism titanium alloy rod of sectional side length 30mm, length 1800mm as incident rod 17 (also can adopt different material hollow tube, circular cross-section rod according to needs), and the incident rod pressurization is set at the distance from the incident rod end 700mm The boss 20 is used for the hydraulic servo control system 18 to pressurize the injection rod. The main shaft transmission rod 22 and the secondary shaft transmission rod 23 are tetragonal prism titanium alloy rods with a section side length of 30 m and a length of 1200 mm (hollow tubes of different materials and circular cross-section rods can also be used as required). The roughness of all waveguide rods is 0.8, and the coaxiality and straightness are within 0.05mm deviation per meter. A pair of 120 ohm strain gauges 5 are pasted on the upper and lower surfaces of the six waveguide rods at a distance of 600 mm from the ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com