Error detection and separation method of high-precision laser measurement system

A laser measurement system and error detection technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of inability to detect and separate the measurement system structure, complex system structure, expensive price, etc., to achieve convenient operation and measurement accuracy High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

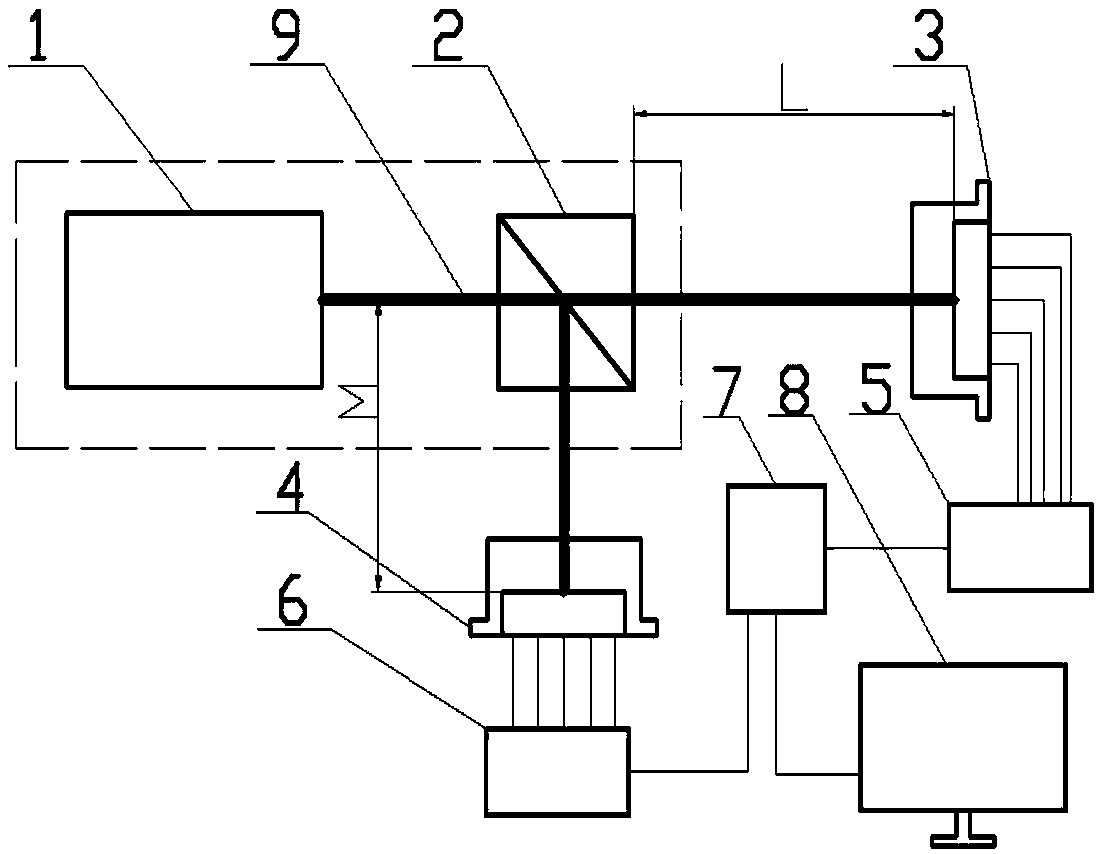

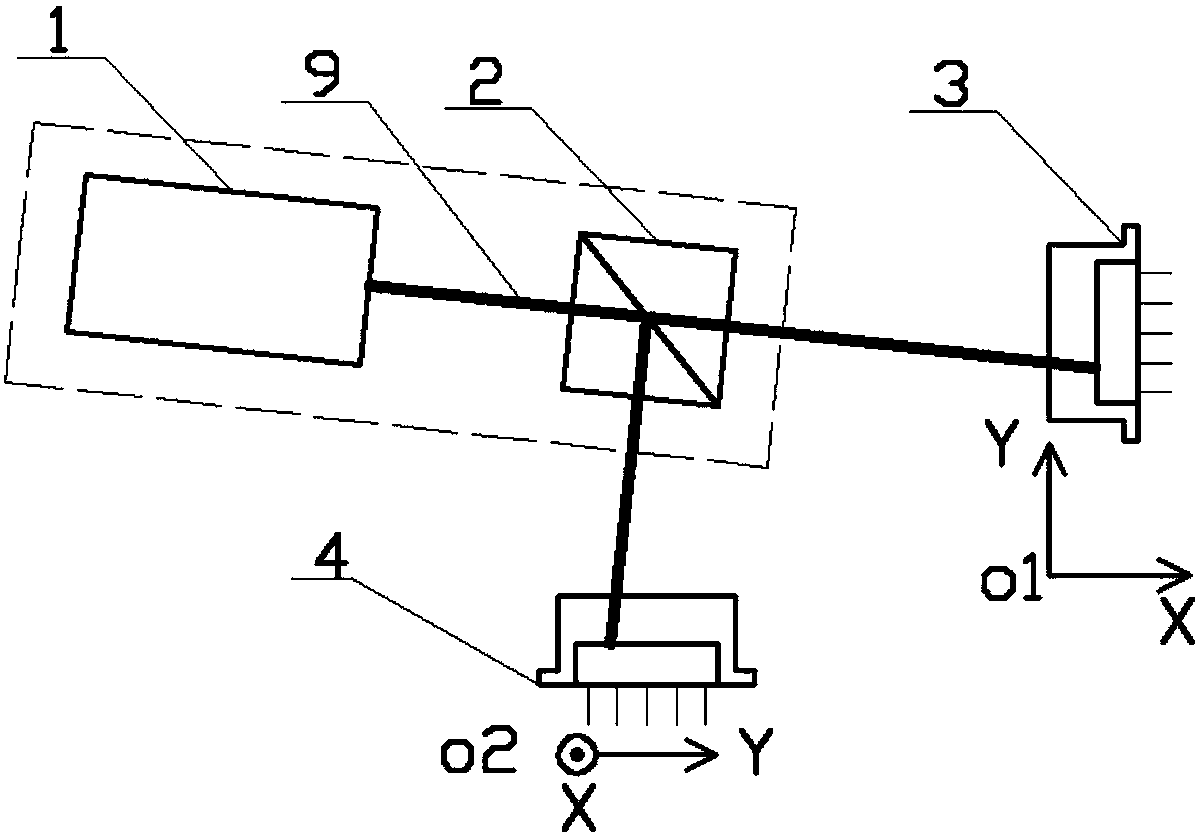

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0019] Use an ordinary semiconductor laser with a power of 5mW and a beam diameter of 3mm as the light source. The beam is irradiated vertically on the surface of the beam splitter prism, and the laser beam is split into two beams at 90 degrees. Location. The distances L and M from the beam splitting prism to the four-quadrant detector ① and the four-quadrant detector ② are 150mm.

[0020] Four-quadrant detectors such as Figure 4 The photosensitive part shown is divided into four parts, and the four quadrants A, B, C, and D are respectively named along the counterclockwise direction. The current generated by each quadrant after laser irradiation is I A , I B , I C , I D , the output current through the current conversion board is converted to the corresponding voltage V ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Beam diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com