Low-hydrogen high-tenacity self-protection flux-cored wire and preparation method thereof

A flux-cored wire, high toughness technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problems of low impact value, large dispersion of low-temperature impact toughness, etc., to avoid rust, good welding process performance, good The effect of all-position welding adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] A method for preparing a low-hydrogen high-toughness self-shielding flux-cored welding wire, mainly comprising the following steps:

[0059] Step 1, material preparation:

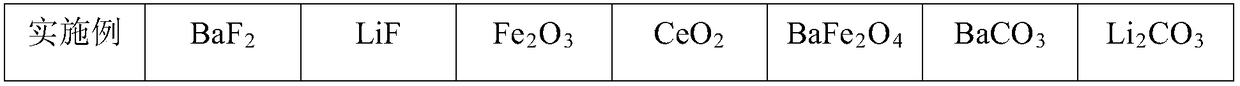

[0060] As shown in Table 1, according to the core ratio of low-hydrogen high-toughness self-shielding flux-cored welding wire, weigh fluoride, oxide, carbonate and sodium borate, and mix the fluoride, oxide and carbonate in the mixer Dry mix evenly to obtain mixed dry powder, dissolve sodium borate in distilled water to make a sodium borate aqueous solution with a concentration of 0.4-2.0 mg / ml;

[0061] Step 2, preprocessing:

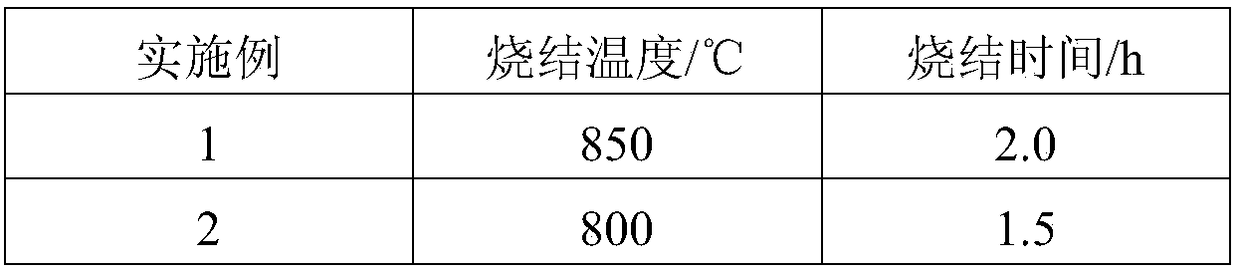

[0062] Add sodium borate aqueous solution to the mixed dry powder for wet mixing, and granulate through a granulator to obtain spherical or ellipsoidal particle powder with a particle size of 2-10mm. Sinter the above-mentioned particle powder in a resistance furnace, sintering temperature, heat preservation The time is shown in Table 2. After air-cooling to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com