Emulsifying equipment for cosmetic production

A technology for emulsification equipment and cosmetics, applied in chemical instruments and methods, chemical/physical processes, mixers with rotary stirring devices, etc., can solve problems such as large vibration of equipment, unstable emulsion, and unfavorable production efficiency of product production lines, etc. To achieve the effect of promoting exchange mixing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

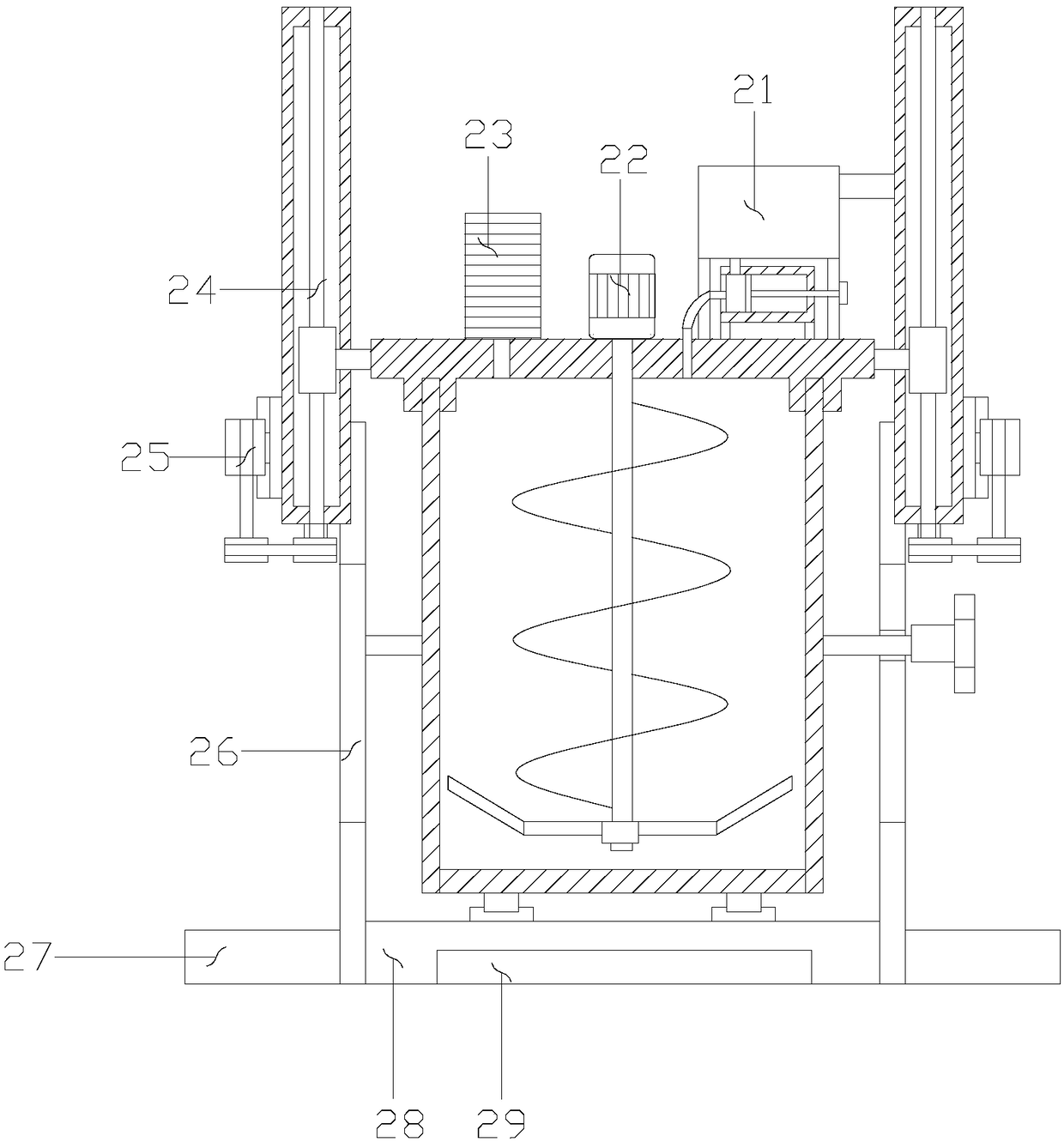

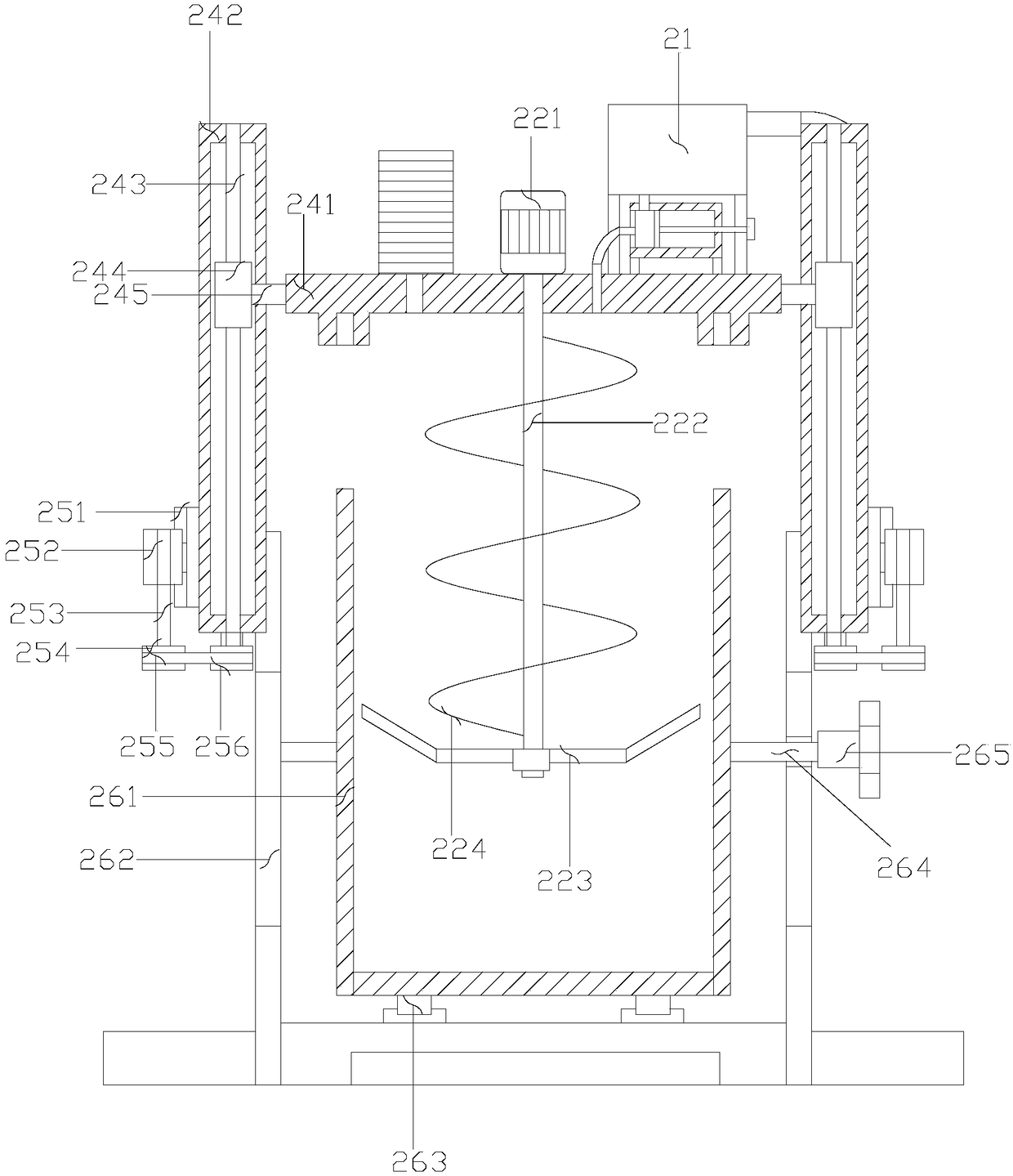

[0021] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of emulsification equipment for the production of cosmetics, its structure includes collection box 1, fast stirring emulsification mechanism 2, stirring rod 3, hydraulic cylinder 4, control panel 5, power supply device 6, frame working frame 7 , the fast stirring and emulsifying mechanism 2 is fixedly arranged on the front end of the frame working frame 7 and welded together between the two, and the collection box 1 is fixedly welded to the lower left corner of the fast stirring and emulsifying mechanism 2 and welded to the frame working frame 7 Together, the right side of the stirring rod 3 is fixedly embedded in the left side of the rapid stirring and emulsifying mechanism 2 and the two are matched and movably connected, and the hydraulic cylinder 4 is fixedly welded to the right side of the rapid stirring and emulsifying mechanism 2 and is tightly connected between the two. The power supply de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com