Permanent magnet synchronous motor drive control real-time voltage regulating circuit based on silicon carbide/gallium nitride MOSFET

A technology of permanent magnet synchronous motor and voltage regulating circuit, which is applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., and can solve the problem of low conversion efficiency, large heat generation of linear power amplifier, and limitation of motor drive control system Power level and other issues, achieve high conversion efficiency, solve the effect of large power amplifier loss and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

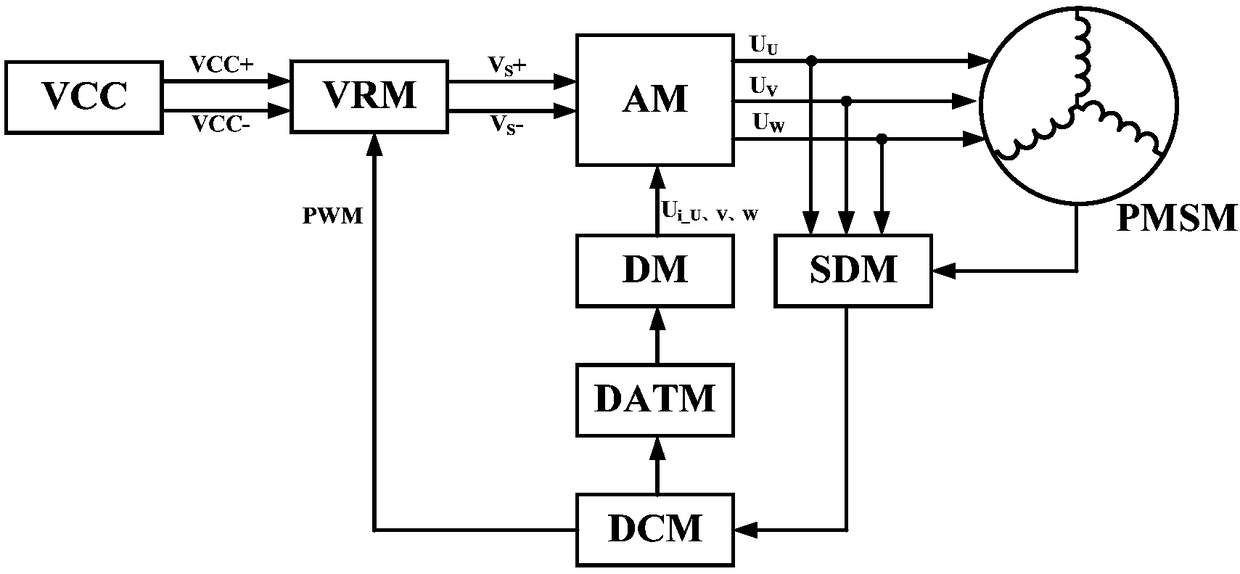

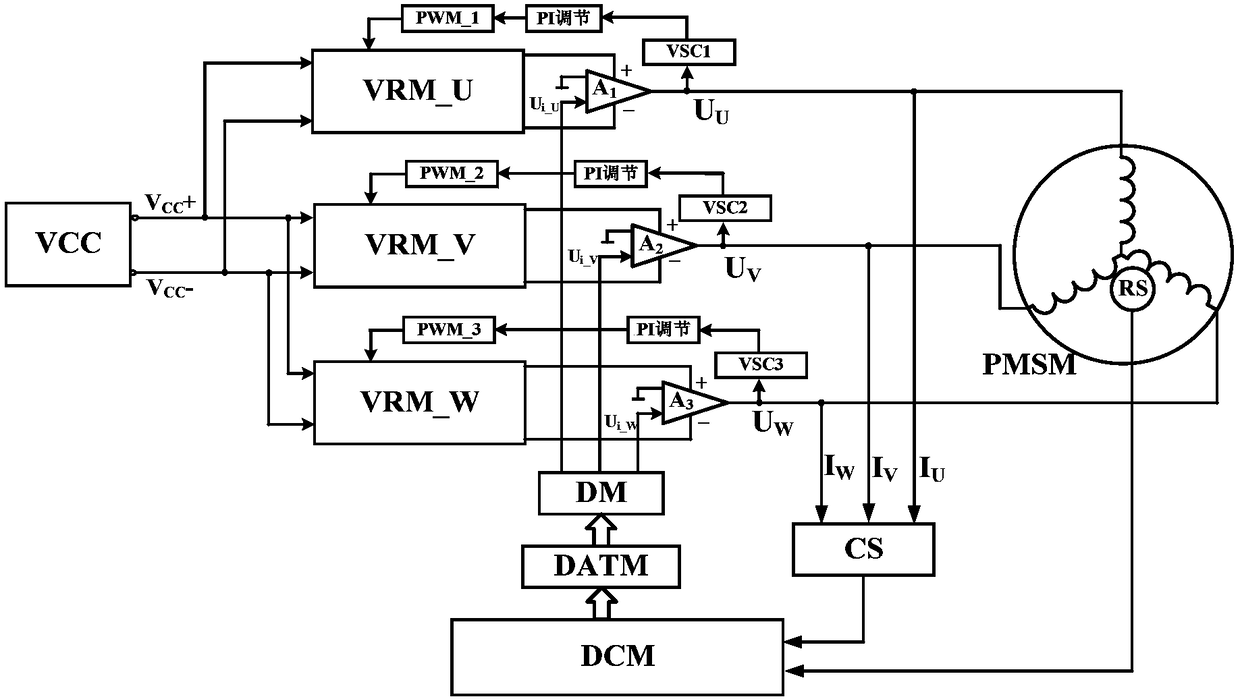

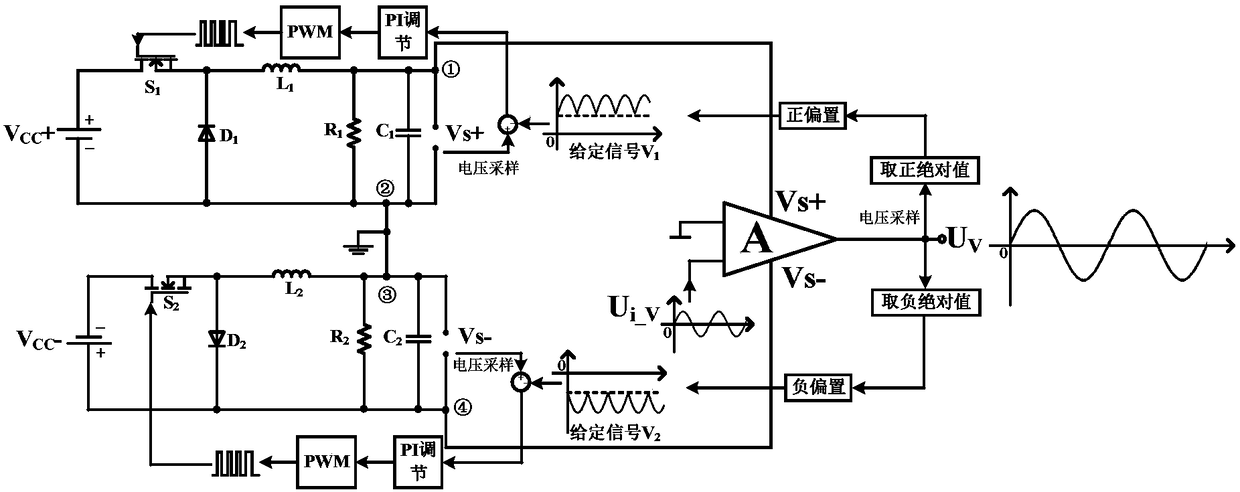

[0023] The implementation of the present invention will be further described below in conjunction with the accompanying drawings. see Figure 1-Figure 4 , the overall structural block diagram of the circuit is attached figure 2 As shown, it includes five parts: power amplifier power supply real-time voltage regulation module (VRM), power amplifier driver module (PAM), digital control module (DCM), signal detection processing module (SDM), and D / A conversion module (DATM).

[0024] Among them, the DSP adopts the 32-bit floating-point high-speed DSP TMS320F28335 of the Texas company in the United States, which has a high-speed processing capability of 150MHz and a 32-bit floating-point processing unit with high precision, low cost, low power consumption, high performance, and high peripheral integration. , a large amount of data and program storage; the switching device uses the CAS300M12BM2 silicon carbide MOSFET of the American CREE company, which has the advantages of fast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com